En-9

6. ELECTRICAL WIRING

6.1. Notes for electrical wiring

WARNING

Wiring connections must be performed by a qualified person in accordance with the

specifications. The voltage rating for this product is 220-240 V at 50 Hz. It should be

operated within the range of 198 to 264 V.

Before connecting the wires, make sure the power supply is OFF.

Use a dedicated power supply circuit. Insufficient power capacity in the electrical circuit

or improper wiring may cause electric shock or fire.

Install a breaker at the power supply for each outdoor unit. Improper breaker selection

can cause electric shock or fire.

Install a leakage circuit breaker in accordance with the related laws and regulations. An

improperly installed electrical box cover can cause serious accidents such as electric

shock or fire through exposure to dust or water.

A circuit breaker is installed in the permanent wiring. Always use a circuit that can trip all

the poles of the wiring and has an isolation distance of at least 2/16 in. (3mm) between

the contacts of each pole.

Use designated cables and power cables. Improper use may cause electric shock or fire

by poor connection, insufficient insulation, or over current.

Do not modify power cable, use extension cable or branch wiring. Improper use may

cause electric shock or fire by poor connection, insufficient insulation or over current.

Connect the connector cable securely to the terminal. Check no mechanical force bears

on the cables connected to the terminals. Faulty installation can cause a fire.

Use crimp-type terminals and tighten the terminal screws to the specified torques,

otherwise, abnormal overheating may be produced and possibly cause serious damage

inside the unit.

Make sure to secure the insulation portion of the connector cable with the cable clamp.

Damaged insulation can cause a short circuit.

Fix cables so that cables do not make contact with the pipes (especially on high

pressure side). Do not make power supply cable and transmission cable come in

contact with valves (Gas).

Never install a power factor improvement condenser. Instead of improving the power

factor, the condenser may overheat.

Be sure to perform the earthing (grounding) work.

Do not connect earthing (grounding) wires to a gas pipe, water pipe, lightning rod or

earthing (grounding) wire for a telephone.

• Connection to a gas pipe may cause a fire or explosion if gas leaks.

•

Connection to a water pipe is not an effective earthing (grounding) method if PVC

pipe is used.

•

Connection to the earthing (grounding) wire of a telephone or to a lightning rod may

cause a dangerously abnormal rise in the electrical potential if lightning strikes.

Improper earthing (grounding) work can cause electric shocks.

Securely install the electrical box cover on the unit. An improperly installed service panel

can cause serious accidents such as electric shock or fire through exposure to dust or

water.

CAUTION

The primary power supply capacity is for the air conditioner itself, and does not include

the concurrent use of other devices.

Do not start operation until the refrigerant is charged completely. The compressor will

fail if it is operated before the refrigerant piping charging is complete.

Transmission cable between indoor unit and outdoor unit is 240 V.

Be sure not to remove thermistor sensor etc. from power wiring and connection wiring.

Compressor may fail if operated while removed.

Start wiring work after closing branch switch and over current breaker.

Use an earth leakage breaker that is capable of handling high frequencies. Because the

outdoor unit is inverter controlled, a high-frequency earth leakage breaker is necessary

to prevent a malfunction of the breaker itself.

When using an earth leakage breaker that has been designed solely for earth (ground)

fault protection, be sure to install a fuse-equipped switch or circuit breaker.

Do not connect the AC power supply to the transmission line terminal board. Improper

wiring can damage the entire system.

Do not use crossover power supply wiring for the outdoor unit.

If the temperature surrounding the breaker is too high, the amperage at which the

breaker cuts out may decrease.

Tightening torque [N·m (lbs·ft)]

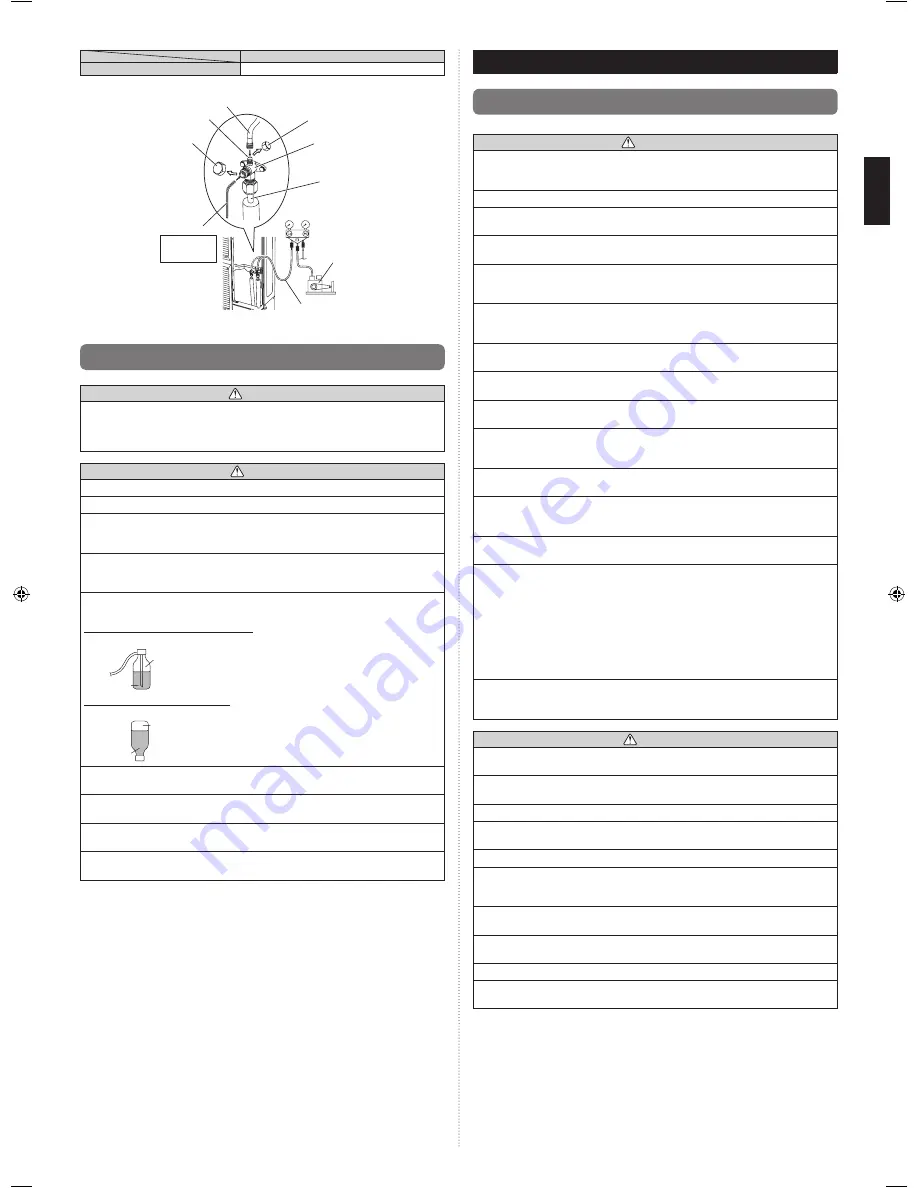

Charging port cap

10 to 12 (7 to 9)

Service hose

Service hose with valve core

Charging port

Blank cap

Hexagon wrench

Connecting pipe

Gauge manifold

Vacuum pump

Charging port cap

3-way valve

Use a 4 mm

hexagon

wrench

5.6. Additional charging

WARNING

When moving and installing the air conditioner, do not mix gas other than the specified

refrigerant R410A inside the refrigerant cycle.

If air or other gas enters the refrigerant cycle, the pressure inside the cycle will rise to an

abnormally high value and cause breakage, injury, etc.

CAUTION

After vacuuming the system, add refrigerant.

Do not reuse recovered refrigerant.

When charging the refrigerant R410A, always use an electronic scales for refrigerant

charging (to measure the refrigerant by weight). Adding more refrigerant than the

specified amount will cause a malfunction.

When charging the refrigerant, take into account the slight change in the composition

of the gas and liquid phases, and always charge from the liquid phase side whose

composition is stable. Adding refrigerant through the gas pipe will cause a malfunction.

Check if the steel cylinder has a siphon installed or not before filling. (There is an

indication “with siphon for filling liquid” on the steel cylinder.)

Filling method for cylinder with siphon

R410A

Gas

Liquid

Set the cylinder vertical and fill with the liquid.

(Liquid can be filled without turning bottom up with the

siphon inside.)

Filling method for other cylinders

R410A

Gas

Liquid

Turn bottom up and fill with liquid.

(Be careful to avoid turning over the cylinder.)

Be sure to use the special tools for R410A for pressure resistance and to avoid mixing

of impure substances.

If the units are further apart than the maximum pipe length, correct operation can not be

guaranteed.

Make sure to back closing valve after refrigerant charging. Otherwise, the compressor

may fail.

Minimize refrigerant release to the air. Excessive release is prohibited under the Freon

Collection and Destruction Law.

9379069762_IM.indb 9

3/4/2016 09:03:15