En-8

8. FINISHING

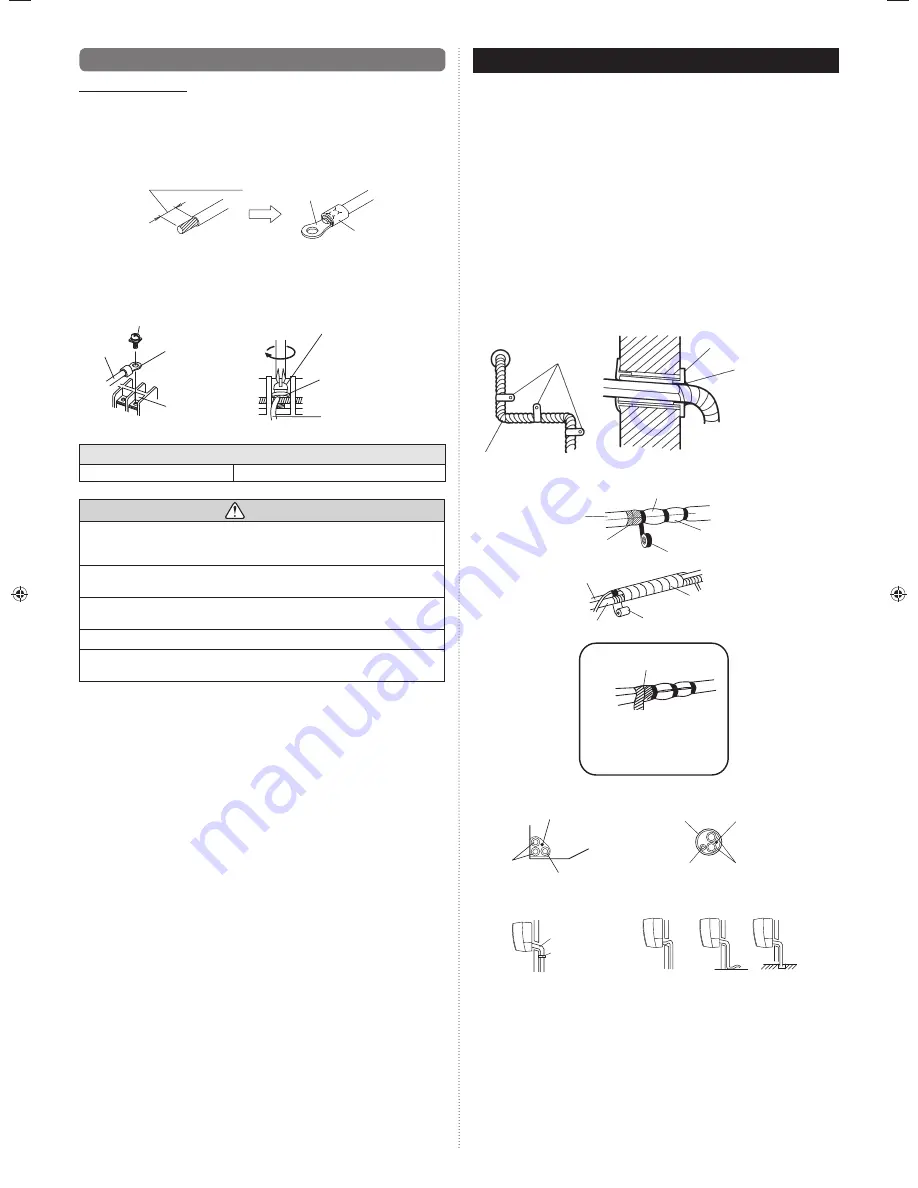

(1) Insulate between pipes.

• Insulate suction and discharge pipes separately.

• For rear, right, and bottom piping, overlap the connection pipe heat insulation and

indoor unit pipe heat insulation and bind them with vinyl tape so that there is no

gap.

• For left and left rear piping, butt the connection pipe heat insulation and indoor

unit pipe heat insulation together and bind them with and vinyl tape so that there

is no gap.

• For left and left rear piping, wrap the area which accommodates the rear piping

housing section with cloth tape.

• For left and left rear piping, bind the connection cable to the top of the pipe with

vinyl tape.

• For left and left rear piping, bundle the piping and drain hose together by wrapping

them with cloth tape over the range within which they

fi

t into the rear piping

housing section.

(2) Temporarily fasten the connection cable along the connection pipe with vinyl tape.

(Wrap to about 1/3 the width of the tape from the bottom of the pipe so that water

does not enter.)

(3) Fasten the connection pipe to the outside wall with a saddle, etc.

(4) Fill the gap between the outside wall pipe hole and the pipe with sealer so that rain

water and wind cannot blow in.

(5) Fasten the drain hose to the outside wall, etc.

Pipe

Saddle*

Outside wall cap*

Sealer putty*

(Outdoors)

*Field supplied

Wall

Seal A is used when the diameter of gas

pipe is Ø12.70 mm (1/2 in.) or more.

Butt connection pipe (heat

insulation) against the indoor

unit pipe (heat insulation) and

wrap with seal A so that there

is no gap.

Overlap the insulation

Vinyl tape

Wrap with cloth tape

Cloth tape

Drain hose

Connection cable

Pipe

Drain hose

Check the following:

GOOD

Drain hose

Saddle

Lifted up

Wave

End in water

Drain hose

Connection pipe

Wall pipe

Connection cable

Left piping

For connection from the left rear

PROHIBITED

Pipe

Connection pipe

(heat insulation)

Bind the pipes together

so that there is no gap.

Indoor unit pipe

(heat insulation)

7.4. How to connect wiring to the terminals

Caution when wiring cable

When stripping off the insulation of a lead wire, always use a special tool such as a wire

stripper. If there is no special tool available, carefully strip the insulation with a knife etc.

(1) Use crimp-type terminals with insulating sleeves as shown in the

fi

gure below to con-

nect to the terminal block.

(2) Securely clamp the crimp-type terminals to the wires using an appropriate tool so that

the wires do not come loose.

Strip : 10 mm (13/32 in.)

Crimp-type

terminal

Sleeve

(3) Use the speci

fi

ed wires, connect them securely, and fasten them so that there is no

stress placed on the terminals.

(4) Use an appropriate screwdriver to tighten the terminal screws. Do not use a screw-

driver that is too small, otherwise, the screw heads may be damaged and prevent the

screws from being properly tightened.

(5) Do not tighten the terminal screws too much, otherwise, the screws may break.

Screw with special washer

Wire

Crimp-type terminal

Terminal blocks

Wire

Screw with special washer

Crimp-type

terminal

(6) See the table below for the terminal screw tightening torques.

Tightening torque [N·m (lbf·in)]

M4 screw

1.2 to 1.8 (11 to 16)

CAUTION

Match the terminal block numbers and connection cable colors with those of the

outdoor unit or branch box.

Erroneous wiring may cause burning of the electric parts.

Connect the connection cables

fi

rmly to the terminal block. Imperfect installation may

cause a

fi

re.

Always fasten the outside covering of the connection cable with the cable clamp. (If

the insulator is chafed, electric discharge may occur.)

Always connect the earth (ground) wire.

Do not use the earth (ground) screw of the indoor unit for the connection other than a

speci

fi

ed outdoor unit or branch box.

9319357041_IM.indb 8

9319357041_IM.indb 8

11/30/2011 1:32:50 PM

11/30/2011 1:32:50 PM

Summary of Contents for 9319357041

Page 14: ......