En-9

9. FRONT PANEL REMOVAL AND INSTALLATION

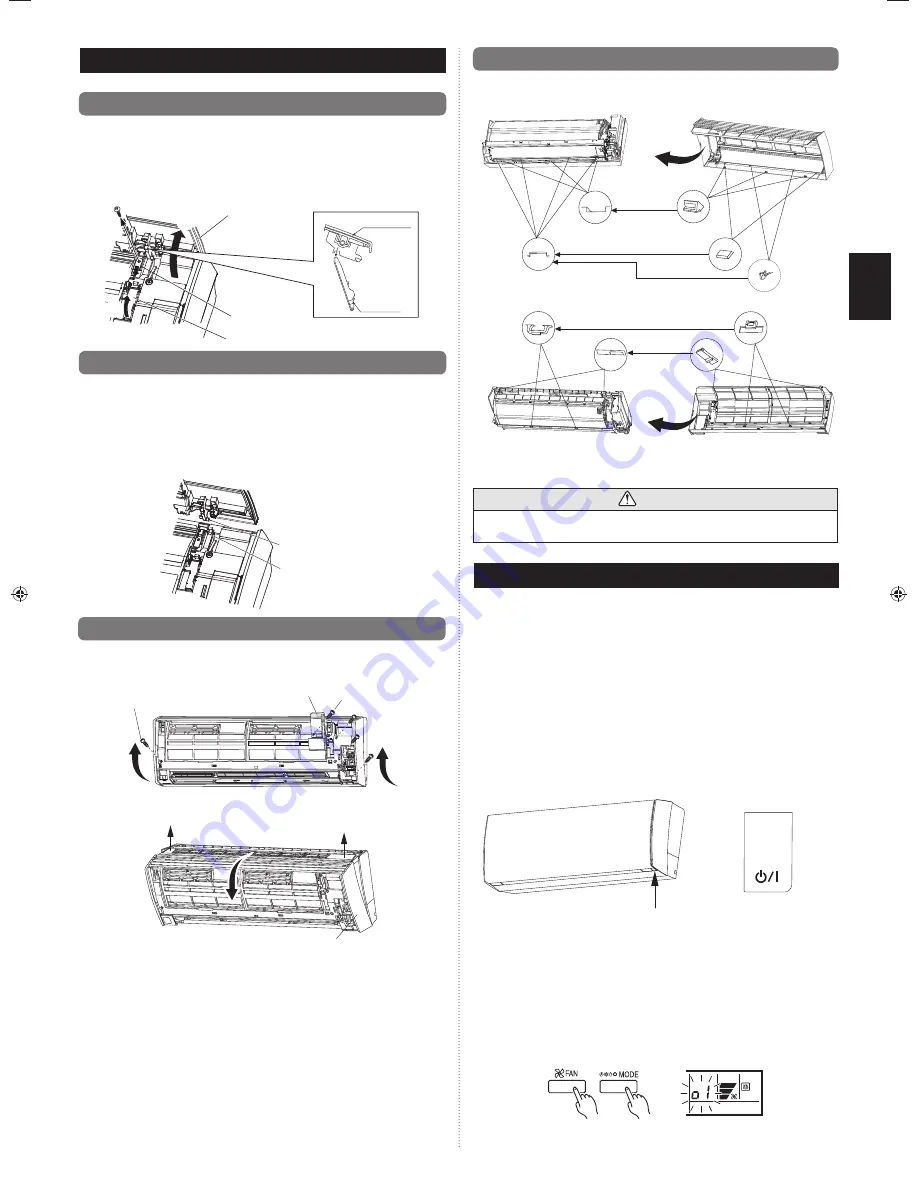

9.1. Intake grille removal

(1) Open the intake grille.

(2) While holding the intake grille, lift up the grille stay and secure the intake grille.

(3) Remove the screws from the arm-cover on the top part of the front panel

(in 2 places, one on the left and one on the right).

(4) Push down the arm-cover grips to release the lock.

(5) Open the intake grille until it is horizontal, and pull it towards you to remove it.

(1)

(2)

(3)

(4)

Intake grille

Arm-cover knob

Grille stay

Intake grille

Grille stay

9.2. Intake grille installation

(1) Make the intake grille horizontal and push the attachment shafts into the holes for

them in the top of the front panel (in 2 places, one on the left and one on the right).

(2) While holding the intake grille, lift up the grille stay and secure the intake grille.

(3) Push the arm-cover grips up, and lock the intake grille attachment shaft.

(4) Fix the arm-cover on the top part of the front panel using screws (in 2 places, one on

the left and one on the right).

(5) Lift up the intake grille a little, and return the grille stay to its original position.

(6) Close the intake grille.

Attachment shaft

Hole

9.3. Front panel removal

(1) Remove intake grille. (Reference the intake grille removal.)

(2) Remove wire cover. (Remove the 1 screw.)

(3) Remove 4 screws.

Screws (4 position)

Wire cover Screw (Wire cover)

(4) The front panel is pulled to the front, raising the upper surface, and a front panel is

removed.

Front panel

9.4. Front panel installation

(1) First,

fi

t the lower part of the front panel, and insert top and bottom hooks. (2 top

sides, 7 bottom sides, 2 center)

Indoor unit

Bottom holes

(3 position)

Bottom hooks

(3 position)

Bottom holes

(4 position)

Center holes

(2 position)

Center hooks

(2 position)

Top hooks

(2 position)

Top holes

(2 position)

Indoor unit

Front panel

Bottom hooks

(2 position)

Bottom hooks

(2 position)

Front panel

(2) Attach the 4 screws.

(3) Attach the wire cover. (Attach the 1 screw.)

(4) Attach the intake grille.

CAUTION

Install the Front panel and Intake grille securely. If installation is imperfect, the Front

panel or Intake grille may fall off and cause injury.

10. TEST RUN

Check items

(1) Is operation of each button on the remote controller unit normal?

(2) Does each lamp light normally?

(3) Do

air

fl

ow direction louvers operate normally?

(4) Is the drain normal?

(5) Do not have an abnormal noise and vibration during operation?

Do not operate the air conditioner in test run for a long time.

[Operation method]

For the operation method, refer to the operating manual.

The outdoor unit, may not operate, depending on the room temperature. In this case,

keep on pressing the MANUAL AUTO button of the indoor unit for more than 10

seconds. The OPERATION indicator lamp (green) and TIMER indicator lamp (orange)

will begin to

fl

ash simultaneously during cooling test run. Then, heating test run will

begin in about 3 minutes when HEAT is selected by the remote control operation. (Please

follow the operating manual for remote control operation.)

(When the air conditioner is running by pressing the test run button, the OPERATION

indicator lamp and TIMER indicator lamp will simultaneously

fl

ash slowly.)

Press and hold MANUAL AUTO

button for 10 seconds

MANUAL AUTO button

When ending the test run, keep on pressing the MANUAL AUTO button of the indoor

unit for more than 3 seconds.

[Using the wired remote controller] (Option)

For the operation method, refer to the operating manual.

(1) Stop the air conditioner operation.

(2) Press the MODE button and the FAN button simultaneously for

2 seconds or more to start the test run.

Test run display

(3) Press the start/stop button to stop the test run.

9319357041_IM.indb 9

9319357041_IM.indb 9

11/30/2011 1:32:51 PM

11/30/2011 1:32:51 PM

Summary of Contents for 9319357041

Page 14: ......