En-11

(4) Auto restart

Enable or disable automatic system restart after a power outage.

(

♦

... Factory setting)

Setting description

Function

number

Setting value

♦

Yes

40

00

No

01

* Auto restart is an emergency function such as for power failure etc. Do not start and stop

the indoor unit by this function in normal operation. Be sure to operate by the control unit,

or external input device.

(5) Indoor room temperature sensor switching function

(Only for Wired remote controller)

The following settings are needed when using the Wired remote controller temperature

sensor.

(

♦

... Factory setting)

Setting description

Function

number

Setting value

♦

No

42

00

Yes

01

* If setting value is “00” :

Room temperature is controlled by the indoor unit temperature sensor.

* If setting value is “01” :

Room temperature is controlled by either indoor unit temperature sensor or remote con-

troller unit sensor.

(6) External input control

“Operation/Stop” mode or “Forced stop” mode can be selected.

(

♦

... Factory setting)

Setting description

Function

number

Setting value

♦

Operation/Stop mode

46

00

(Setting forbidden)

01

Forced stop mode

02

(7) Room temperature control switching

• This setting is used to set the room temperature control method when the wired remote

controller is selected by the Indoor Room Temperature Sensor Switching Function.

(

♦

... Factory setting)

Setting description

Function

number

Setting value

♦

Control by the sensors of both the

indoor unit and the wired remote

controller.

48

00

Control only by the sensor of the

wired remote controller

01

Setting record

•

Record any changes to the settings in the following table.

Setting

Setting Value

(1) Filter sign

(2) Cooling room temperature correction

(3) Heating room temperature correction

(4) Auto restart

(5) Indoor room temperature sensor switching

function

(6) External input control

(7) Room temperature control switching

After completing the FUNCTION SETTING, be sure to turn off the power and turn it on

again.

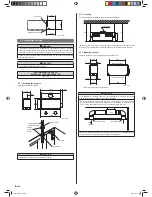

SETTING THE ROOM TEMPERATURE DETECTION

LOCATION

The detection location of the room temperature can be selected from the following 2 examples.

Choose the detection location that is best for the installation location.

A. Indoor unit setting (factory setting)

The room temperature is detected by the indoor unit temperature sensor.

(1) When the THERMO SENSOR button is pressed, the lock display

fl

ashes because the

function is locked at the factory.

A

Indoor unit

B. Indoor unit/remote controller setting (room tempera-

ture sensor selection)

The temperature sensor of the indoor unit or the remote controller can be used to detect

the room temperature.

(1) Enable the room temperature sensor selection in FUNCTION SETTING, which will be

“(5) Indoor room temperature sensor switching function”.

(2) Press the THERMO SENSOR button for 5 seconds or more to select the temperature

sensor of the indoor unit or the remote controller.

B

Indoor unit

CAUTION

When select the “Remote controller setting”, if the detected

temperature value between the temperature sensor of the in-

door unit and the temperature sensor of the remote controller

varies signi

fi

cantly, it is likely to return to the control status of

temperature sensor of the indoor unit temporarily.

As the temperature sensor of remote controller detects the temperature near the

wall, when there is a certain difference between the room temperature and the

wall temperature, the sensor will not detect the room temperature correctly some-

times.

Especially when the outer side of the wall on which the sensor is positioned is

exposed to the open air, it is recommended to use the temperature sensor of the

indoor unit to detect the room temperature when the indoor and outdoor tempera-

ture difference is signi

fi

cant.

The temperature sensor of the remote controller is not only used when there is a

problem in the detection of the temperature sensor of the indoor unit.

NOTES

If the function to change the temperature sensor is used as shown in examples A (other

than example B), be sure to lock the detection location. If the function is locked, the lock

display

will

fl

ash when the THERMO SENSOR button is pressed.

9379123037-02.indb 11

9379123037-02.indb 11

7/4/12 3:47 PM

7/4/12 3:47 PM