En-3

Energy-saving combination

Combination (HP)

8

10

12

14

16

18

20

22

24

26

28

Outdoor Unit 1 (HP)

–

–

–

–

8

–

–

14

8

10

12

Outdoor Unit 2 (HP)

–

–

–

–

8

–

–

8

8

8

8

Outdoor Unit 3 (HP)

–

–

–

–

–

–

–

–

8

8

8

Maximum Connectable

Indoor Unit

*

*

*

*

30

*

*

33

36

39

42

Combination (HP)

30

32

34

36

38

40

42

44

46

48

Outdoor Unit 1 (HP)

14

12

14

14

–

14

14

16

–

–

Outdoor Unit 2 (HP)

8

12

12

14

–

14

14

14

–

–

Outdoor Unit 3 (HP)

8

8

8

8

–

12

14

14

–

–

Maximum Connectable

Indoor Unit

45

48

48

48

*

48

48

48

*

*

* Means that the energy-saving combination is unavailable.

When connecting outdoor units, install the outdoor unit with the largest nominal system capac-

ity nearest to the refrigerant pipe and indoor unit, followed by those with lesser nominal system

capacities. (Outdoor unit 1

≥

Outdoor unit 2

≥

Outdoor unit 3)

Optional parts

2. 5.

CAUTION

The following parts are optional parts speci

fi

c to R410A refrigerant.

Do not use parts other than those listed below.

Outdoor unit branch kit

2. 5. 1.

Model

Total cooling capacity of indoor unit (kW)

UTP-CX567A, UTR-CP567X

ALL

Separation tube

2. 5. 2.

Model

Total cooling capacity of indoor unit (kW)

UTP-AX090A , UTR-BP090X

28.0 or less

UTP-AX180A , UTR-BP180X

28.1 to 56.0

UTP-AX567A , UTR-BP567X

56.1 or more

Header

2. 5. 3.

3-6 branches

3-8 branches

Total cooling capacity of indoor unit (kW)

UTR-H0906L

UTR-H0908L

28.0 or less

UTR-H1806L

UTR-H1808L

28.1 to 56.0

INSTALLATION WORK

3.

Please obtain the approval of the customer when selecting the location of installation

and installing the main unit.

Selecting an installation location

3. 1.

WARNING

Install the unit in a location that can withstand its weight, and where it will not topple

or fall.

Calculate the proper refrigerant concentration if you will be installing it in an en-

closed location.

Total amount of replenished refrigerant in refrigerant facility (kg)

≤

Refrigerant concentration (kg/m

3

)

Capacity of smallest room where unit is installed (m

3

)

(0.3kg/m

3

)

If the results of the calculation exceed the concentration limit, increase the room

surface area or install a ventilation duct.

CAUTION

Select an installation location by observing the following precautions:

Install the unit level. (Within 3 degrees)

Install this unit in a location with good ventilation.

If the unit must be installed in an area within easy reach of the general public, install

as necessary a protective fence or the like to prevent their access.

Install the unit in an area that would not inconvenience your neighbors, as they could

be affected by the air

fl

ow coming out from the outlet, noise, or vibration.

If it must be installed in proximity to your neighbors, be sure to obtain their approval.

If the unit is installed in a cold region that is affected by snow accumulation, snow fall,

or freezing, take appropriate measures to protect it from those elements.

To ensure a stable operation, install inlet and outlet ducts.

Install the unit in an area that would not cause problems even if the drain water is

discharged from the unit. Otherwise, provide drainage that would not affect people or

objects.

CAUTION

Install the unit in an area that has no heat sources, vapors, or the risk of the leakage

of

fl

ammable gas in the vicinity.

Install the unit in an area that is away from the exhaust or vent ports that discharge

vapor, soot, dust, or debris.

Install the indoor unit, outdoor unit, power supply cable, transmission cable and

remote control cable at least 1 meter away from a television or radio.

The purpose of this is to prevent TV reception interference or radio noise. (Even if

they are installed more than 1 meter apart, you could still receive noise under some

signal conditions.)

Keep the length of the piping of the indoor and outdoor units within the allowable

range.

For maintenance purposes, do not bury the piping.

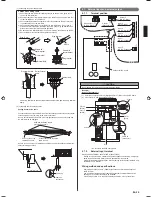

Drain processing

3. 2.

The drain water is discharged from the bottom of the equipment. Construct a drain

•

ditch around the base and discharge the drain water properly.

When installing on a roof, perform

fl

oor waterproo

fi

ng properly.

•

Drain processing:

The drain water from the base of the outdoor unit may generate during operations.

•

Perform drain processing, as necessary.

When you want to prevent the drain water from leaking at the perimeter, construct

•

a ditch for the drain water as shown in the

fi

gure.

Provide a central drain pan, as necessary.

•

Outdoor unit

10mm or more

50mm or

more

Installation dimensions

3. 3.

CAUTION

When installing the outdoor unit, pay attention to the following items.

Provide suf

fi

cient installation space, such as transportation route, maintenance

space, ventilation space, refrigerant piping space, and passageways.

Pay attention to the speci

fi

cations of the installation space as shown in the

fi

gure.

If the unit is not installed according to speci

fi

cations, it may cause short circuit or

poor performance. The unit may be prone to lapse into non-operation due to high

pressure protection.

Do not place obstructions in the air

fl

ow outlet direction. If there is an obstruction in

the outlet direction, install an outlet duct.

When there is a wall in front of the unit, provide a space of 500mm or more as

maintenance space.

When there is a wall at the left side of the unit, provide a space of 30mm or more

as maintenance space.

An outdoor temperature of 35 degrees in air-conditioned operation is assumed for

the installation space in this item. If the outdoor temperature exceeds 35 degrees

and the outdoor unit is operating at a load exceeding its rated ability, provide a

larger inlet space.

If you are installing more outdoor units than indicated here, please ensure suf

fi

cient

space or consult your distributing agent as it may affect the performance due to

short circuit and other problems.

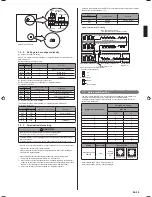

When install near by limited height wall

3. 3. 1.

Single and multiple installations

(1)

There are no restrictions on the height of the side wall.

•

Provide installation spaces L1 and L2 in accordance with the table below according

•

to the wall height (front side, rear side) conditions.

Provide installation spaces other than L1 and L2 in accordance with the conditions

•

shown in the

fi

gure below.

Ventilation resistance can be ignorable when the distance from a wall or product,

•

etc. is larger than 2m.

Wall height condition

Necessary installation space

When H1 is 1500 (mm) or less

L1

≥

500 (mm)

When H1 is 1500 (mm) or more

L1

≥

500+h1÷2 (mm)

When H2 is 500 (mm) or less

L2

≥

100 (mm)

When H2 is 500 (mm) or more

L2

≥

100+h2÷2 (mm)

9378945104-01_IM.indb Sec1:3

9378945104-01_IM.indb Sec1:3

2013-3-12 14:08:13

2013-3-12 14:08:13