En-3

Tapping screw A

(Ø4×10)

6

For suspending the RB unit from

ceiling

Tapping screw B

(Ø4×25)

4

For suspending the RB unit from

wall

Cable tie

2

For mounting the transmission

cable

Cable clamp

1

For mounting the cable

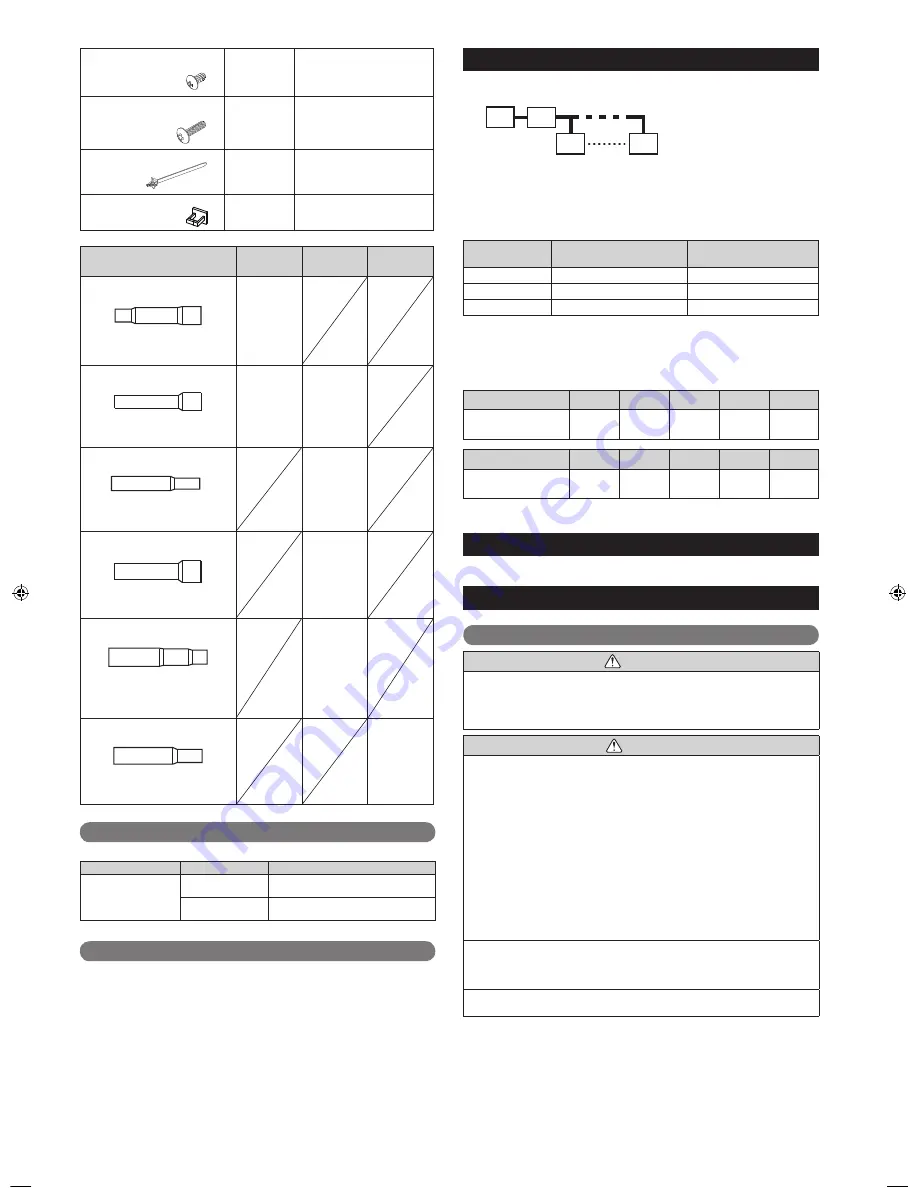

Reducer type [in (mm)]

UTP-

RU01AH

UTP-

RU01BH

UTP-

RU01CH

Reducer-A

a

b

a: 3/8 (9.52) [O.D.]

b: 1/2 (12.7) [I.D.]

4

Reducer-B

a

b

a: 1/2 (12.7) [O.D.]

b: 5/8 (15.88) [I.D.]

2

1

Reducer-C

a

b

a: 1/2 (12.7) [O.D.]

b: 3/8 (9.52) [I.D.]

1

Reducer-D

a

b

a: 3/4 (19.05) [O.D.]

b: 7/8 (22.22) [I.D.]

2

Reducer-E

a

b

с

a: 3/4 (19.05) [O.D.]

b: 1/2 (12.7) [I.D.]

c: 5/8 (15.88) [I.D.]

2

Reducer-F

a

b

a: 3/4 (19.05) [O.D.]

b: 5/8 (15.88) [I.D.]

1

2.4. Optional parts

The following optional parts are available.

Description

Model No.

Application

External connect kit

UTY-XWZXZ6

For external input

(Dry contact terminal / CNA01)

UTY-XWZXZB

For external input

(Apply voltage terminal / CNA02)

2.5. About unit of the length

All Fujitsu General products are manufactured to metric units and tolerances. United

States customary units are provided for reference only.

In cases where exact dimensions and tolerances are required, always refer to metric

units.

3. PRODUCT SELECTION

• Select the RB unit to

fi

t the total capacity and number of the indoor units to be con-

nected downstream. (Refer to Tables 1 and 2)

I.U.=Indoor unit

RB=RB unit

O.U.=Outdoor unit

O.U.

RB

I.U.

I.U.

Calculation example: If the connected indoor units model code is 07, 09, 12 and 18.

Q1=

7,500 Btu/h + 9,500 Btu/h + 12,000 Btu/h +

18,000 Btu/h=47,000 Btu/h

→

Select “UTP-RU01BH”

Table 1) Conditions in which connection is possible

Model Name

Indoor unit capacity

Maximum number of con-

nectable indoor units

UTP-RU01AH

7,500

≤

Q1

≤

27,000 Btu/h

Up to 3 units

UTP-RU01BH

7,500

≤

Q1

≤

60,000 Btu/h

Up to 8 units

UTP-RU01CH

7,500

≤

Q1

≤

96,000 Btu/h

Up to 8 units

* Indoor units connected downstream of the RB unit can operate all in the same operat-

ing mode. Indoor units within the same RB group cannot simultaneously operate heat-

ing and cooling.

Table 2) Indoor unit model codes and model selection capacity

Model code

07

09

12

14

18

Indoor unit capacity

[Btu/h]

7,500

9,500

12,000

14,000

18,000

Model code

24

30

36

48

60

Indoor unit capacity

[Btu/h]

24,000

30,000

36,000

48,000

60,000

• For connectable indoor units, refer to the catalogue or the Design & Technical manual.

4. PIPING SPECIFICATIONS

For details of piping speci

fi

cations, refer to the outdoor unit installation manual.

5. INSTALLATION WORK

5.1. Selecting an installation location

WARNING

Take into consideration whether the place you install the main unit can fully with-

stand its weight.

For hanger bolts, use embedded inserts or embedded foundation bolts in the case

of new installation, and use a hole-in-anchor if already installed, and attach in a

way so that the unit’s weight can be supported.

CAUTION

Do not install this unit in the following areas:

• Area with high salt content, such as at the seaside. It will deteriorate metal parts,

causing the parts to fail or the unit to leak water.

• Area

fi

lled with mineral oil or containing a large amount of splashed oil or steam,

such as a kitchen. It will deteriorate plastic parts, causing the parts to fail or the unit

to leak water.

• Area that generates substances that adversely affect the equipment, such as sulfu-

ric gas, chlorine gas, acid, or alkali. It will cause the copper pipes and brazed joints

to corrode, which can cause refrigerant leakage.

• Area containing equipment that generates electromagnetic interference. It will cause

the control system to malfunction, preventing the unit from operating normally.

• Area that can cause combustible gas to leak, contains suspended carbon

fi

bers or

fl

ammable dust, or volatile in

fl

ammables such as paint thinner or gasoline. If gas

leaks and settles around the unit, it can cause a

fi

re.

• Area where small animals may live. It may cause failure, smoke or

fi

re if small

animals enter and touch internal electrical parts.

• Area where animals may urinate on the unit or ammonia may be generated.

Install this unit, power supply cable and transmission cable at least 40 in (1 m)

away from a television or radio receivers. The purpose of this is to prevent TV

reception interference or radio noise. (Even if they are installed more than 40 in (1 m)

apart, you could still receive noise under some signal conditions.)

If children under 10 years old may approach the unit, take preventive measures so

that they cannot reach the unit.

Select the place to install the product after taking into consideration the following condi-

tions, and after obtaining approval from the customer.

• Install this unit in a location that has strong support and no vibrations.

• Install in a location that has enough space for this unit installation.

• Install in a well-ventilated area.

• Install in a location that is not exposed to high temperatures or humidity over a long

periods.

• Do not install the unit near a bedroom. Refrigerant noise may be heard from the pip-

ing.

9366249030-05_IM.indb Sec1:3

9366249030-05_IM.indb Sec1:3

2015/2/26 13:11:33

2015/2/26 13:11:33