En-7

Thicknesses of Annealed Copper Pipes (R410A)

Pipe outside diameter [in

(mm)]

Thickness [in

(mm)] *1

Material

1/4 (6.35)

0.032 (0.80)

COPPER JIS H3300 C1220T-O

or equivalent

(Allowable tensile stress

≥

33

(N/mm

2

))

3/8 (9.52)

0.032 (0.80)

1/2 (12.7)

0.032 (0.80)

5/8 (15.88)

0.039 (1.00)

3/4 (19.05)

0.047 (1.20)

7/8 (22.22)

0.039 (1.00)

COPPER JIS H3300 C1220T-

H or equivalent

(Allowable tensile stress

≥

61

(N/mm

2

))

*1 Endurance pressure of the pipes :609 psi (4.2 MPa)

6.3. Pipe connection

6.3.1. Brazing

CAUTION

If air or different type of refrigerant enters the refrigeration cycle, the internal

pressure in the refrigeration cycle will become abnormally high and prevent the unit

from exerting its full performance.

Apply nitrogen gas while brazing the pipes.

Nitrogen gas pressure: 2.9 psi (0.02 MPa)

(= suf

fi

cient pressure to be felt on the back

of your hand or more)

Pressure regulating valve

Brazing area

Nitrogen gas

Cap

If a pipe is brazed without applying nitrogen gas, it will create an oxidation

fi

lm.

This can degrade performance or damage the parts in the unit (such as the

compressor or valves).

Do not use

fl

ux to braze pipes. If the

fl

ux is the chlorine type, it will cause the pipes

to corrode.

In addition, if the

fl

ux contains

fl

uoride, it will affect the refrigerant piping system due

to deterioration of refrigerant oil.

For brazing material, use phosphor copper that does not require

fl

ux.

6.3.2. Bending pipes

The pipes are shaped by your hands. Be careful not to collapse them. Do not bend the

pipes in an angle more than 90°.

When pipes are repeatedly bent or stretched, the material will harden, making it dif

fi

cult

to bend or stretch them any more. Do not bend or stretch the pipes more than 3 times.

CAUTION

To prevent breaking of the pipe, avoid sharp bends. Bend the pipe with a radius of

curvature of 3-15/16 in (100 mm) or over.

If the pipe is bent repeatedly at the same place, it will break.

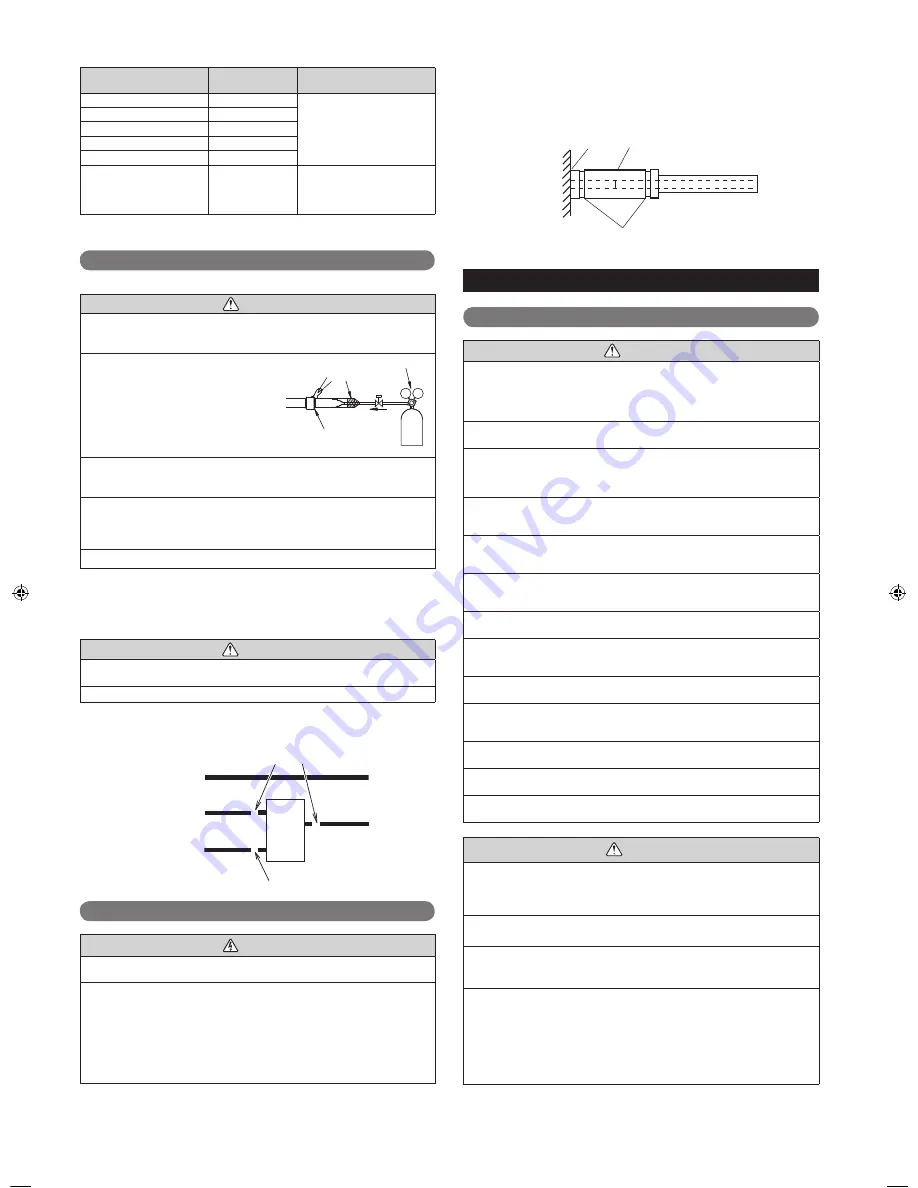

6.3.3. Pipe connection

Liquid pipe

Suction

gas pipe

unit

RB

Discharge

gas pipe

The pipe can be connected by brazing

Brazing

Brazing

RB

unit

6.4. Installing heat insulation

CAUTION

Insulate the suction gas pipe, discharge gas pipe, liquid pipe, and gas pipe with heat

insulation.

Use heat insulation with heat resistance above 248 °F (120 °C).

In addition, if the humidity level at the installation location of the refrigerant piping is

expected to exceed 70%, install heat insulation around the refrigerant piping. If the

expected humidity level is 70-80%, use heat insulation that is 9/16 in (15 mm) or

thicker and if the expected humidity exceeds 80%, use heat insulation that is 13/16 in

(20 mm) or thicker.

If heat insulation is used that is not as thick as speci

fi

ed, condensation may form on

the surface of the insulation. In addition, at 68 °F (20 °C), use heat insulation with

heat conductivity of 0.045 W/(m·K) or less.

6.4.1. Piping insulation

(1) After the sealing test is complete, carry out insulation work.

(2)

Insulate all pipes and piping connection parts so that there is no gap in it.

(3) Firmly connect the terminal part (a) so that no air comes in or out.

(4)

Do not squeeze the cable ties excessively so as to ensure that the insulation

material is thick.

(a)

Insulation (Locally purchased)

Cable tie (Locally purchased)

RB Unit

7. ELECTRICAL WIRING

7.1. Safety precautions for electrical wiring

WARNING

Electrical work must be performed in accordance with this Manual by a person

certi

fi

ed under the national or regional regulations. Be sure to use a dedicated circuit

for the unit.

An insufficient power supply circuit or improperly performed electrical work can

cause serious accidents such as electric shock or

fi

re.

Before starting work, check that power is not being supplied to the RB unit, indoor

unit and outdoor unit.

For wiring, use the prescribed type of cables, connect them securely, making sure

that there are no external forces of the cables applied to the terminal connections.

Improperly connected or secured cables can cause serious accidents such as

overheating the terminals, electric shock, or

fi

re.

Securely install the electrical box cover on the unit.

An improperly installed electrical box cover can cause serious accidents such as

electric shock or

fi

re through exposure to dust or water.

Use the included connection cables and power cables or ones specified by the

manufacturer. Improper connections, insufficient insulation, or exceeding the

allowable current can cause electric shock or

fi

re.

Do not modify the power cables, use extension cables, or use any branches in the

wiring. Improper connections, insufficient insulation, or exceeding the allowable

current can cause electric shock or

fi

re.

Match the terminal block numbers and connection cable colors with those of the

indoor unit or outdoor unit. Erroneous wiring may cause burning of the electric parts.

Securely connect the connection cables to the terminal board. In addition, secure

the cables with wiring holders. Improper connections, either in the wiring or at the

ends of the wiring, can cause a malfunction, electric shock, or

fi

re.

Always fasten the outside covering of the connection cable with the cable clamp. (If

the insulator is chafed, electric discharge may occur.)

We suggest installing GFEB breakers or follow local electrical code. When installing

this system, install using ground fault equipment breakers (GFEB) to reduce the risk

of leaking current which result in electric shock or potential

fi

re.

Always connect the earth (ground) cable.

Improper earthing (grounding) work can cause electric shocks.

Perform wiring work in accordance with standards so that the air conditioner can be

operated safely and positively.

If the supply cable is damaged, it must be replaced by the manufacturer, its service

agent or similarly quali

fi

ed persons in order to avoid a hazard.

CAUTION

Earth (Ground) the unit.

Do not connect the earth (ground) cable to a gas pipe, water pipe, lightning rod, or

a telephone earth (ground) cable.

Improper earthing (grounding) may cause electric shock.

Do not connect power supply cables to the transmission terminals, as this will

damage the product.

Never bundle the power supply cable and transmission cable, together.

Separate these cable by 2 in (50 mm) or more.

Bundling these cables together will cause miss operation or breakdown.

When handling PC board, static electricity charged in the body may cause

malfunction of the PC board. Follow the cautions below:

• Establish an earth (ground) for the RB units, indoor units, outdoor units and

peripheral devices.

• Cut power (breaker) off.

• Touch metal part of the RB units, indoor units and outdoor units for more than

10 seconds to discharge static electricity charged in the body.

• Do not touch terminals of parts and patterns implemented on PC board.

9366249030-05_IM.indb Sec1:7

9366249030-05_IM.indb Sec1:7

2015/2/26 13:11:33

2015/2/26 13:11:33