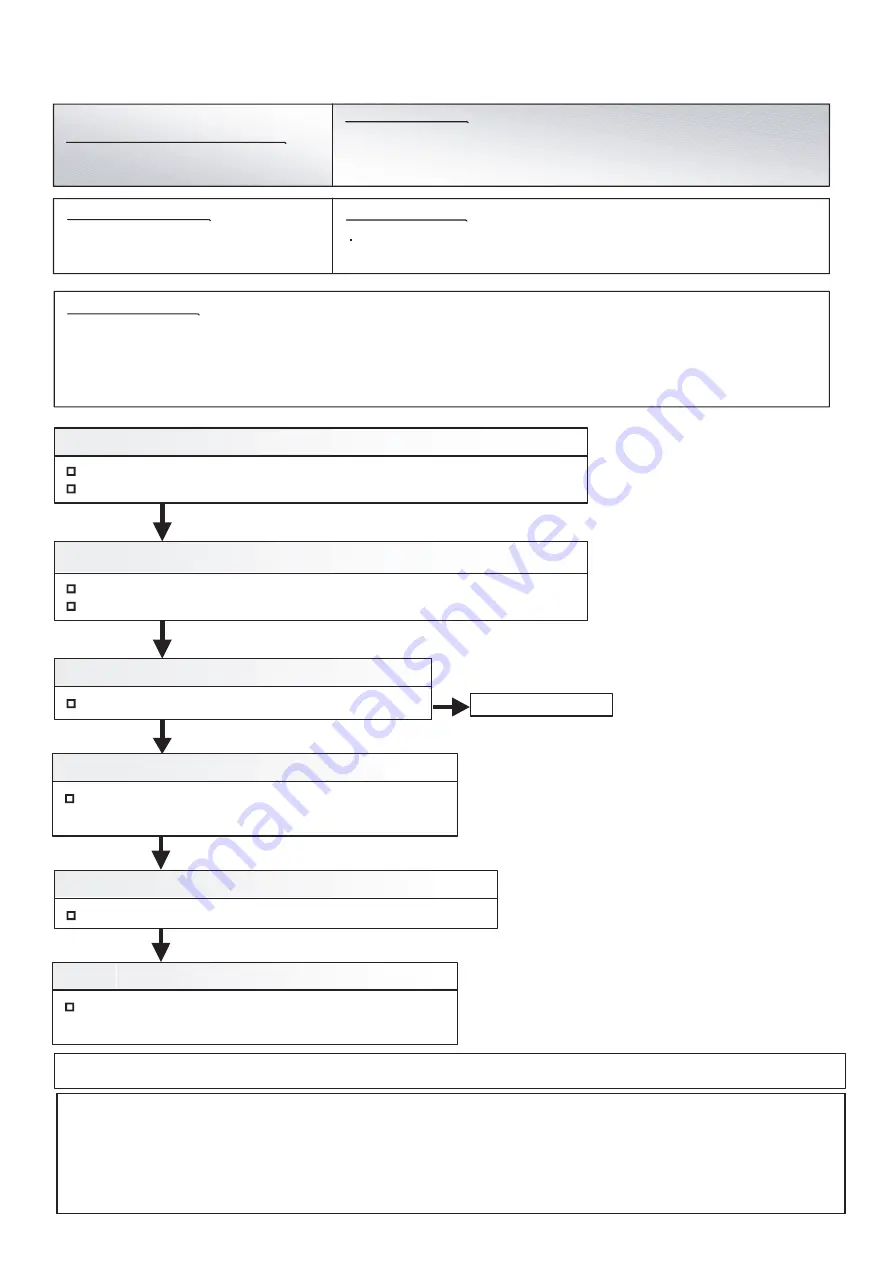

Rush Current Limiting Resistor

Temp Rise Protection

Inverter PCB

1. Magnetic relay (for INV) coil side wiring disconnection, open

2. Power supply to Filter PCB (INV) to Inverter PCB wiring disconnection, open

3. Magnetic relay activation circuit defective

4. Main PCB to Inverter PCB wiring disconnection, open

5. Main PCB output

AC208- 230V

on CN130 defective

Main PCB defective (output

AC208- 230V

on CN130 for Magnetic relay (INV) defective)

"Protection stop by "Rush current limiting resistor temperature rise detection''

of inverter PCB" was generated 2 times.

OK

OK

OK

Check Point 1 : Check the magnetic relay (for invertert) coil side wiring

Connector and wiring connection state check

Cable open check

Cable open check

Check Point 2 : Check Power supply to Filter PCB (INV) to inverter PCB wiring

Connector and wiring connection state check

Check Point 3-1 : Magnetic relay activation circuit

Chack the DC Voltage (12V) of

CN330 on

INVERTER PCB

Check Point 5 : Main PCB output

AC208- 230V

for Magnetic relay

Check the

AC208- 230V

of CN130 on Main PCB

Indoor Unit : Operation LED 9 times Flash, Timer LED 15 Times Flash,

Filter LED Continuous Flash.

Outdoor Unit : E. 6 8. 2

Error Code : 9 U / 6 8

Trouble shooting 33 E68. 2

Indicate or Display:

Detective Actuators:

Detective details:

OUTDOOR UNIT Error Method:

Forecast of Cause :

After fixing the problem and for canceling the Error, Error Reset (F3-40) will be required after power reset

OK

OK

Check Point 4 : Check the wiring (Main PCB to Inverter PCB)

Replace Inverter PCB

NG

Check the wiring connection.

(CN138 on Main PCB to CN330 on Inverter PCB)

Check Point 6 : Replace Main PCB

Change Main PCB and set up the original address.

Caution

By changing of DIP SW 4-2 to ON, the Back-up operation can start when the active outdoor unit exists on the multi outdoor unit connection.

(Stand alone outdoor unit is impossible)

The following conditions will be concerned in use of back-up operation. (Please do not use the system with back-up operation for long time.)

- The operating compressor life time becomes shorter.

- The operating performance may drop due to the limited active compressor(s).

- The compressor may stop frequently by protection controlling.

*In order to keep the operating capacity, the release of the Low noise mode setting might be necessary.

04-42

Summary of Contents for Airstage UTP-RU01AH

Page 1: ...SERVICE MANUAL 208 230V 60Hz ...

Page 5: ...1 TEST RUN ...

Page 6: ......

Page 34: ...2 OUTDOOR UNIT OPERATION CONTROL ...

Page 59: ...3 INDOOR UNIT OPERATION ...

Page 60: ......

Page 82: ......

Page 83: ...4 TROUBLE SHOOTING ...

Page 84: ......

Page 186: ...04 96 0 24 AOUA120 208 230 AOUA72 90 0 19 RED WHITE BLACK U V W ...

Page 208: ...5 APPENDING DATA UNIT ...

Page 209: ......

Page 215: ...CASSETTE TYPE MODELS AUUB18TLAV AUUB24TLAV AUUB30TLAV AUUB36TLAV 05 06 ...

Page 217: ...MEDIUM STATIC PRESSURE DUCT TYPE MODEL ARUM24TLAV 05 08 MODEL ARUM30TLAV ARUM36TLAV ...

Page 218: ...HIGH STATIC PRESSURE DUCT TYPE MODELS ARUH36TLAV ARUH48TLAV ARUH60TLAV 05 09 ...

Page 219: ...FLOOR CEILING TYPE MODELS ABUA12TLAV ABUA14TLAV ABUA18TLAV ABUA24TLAV 05 10 ...

Page 220: ...CEILING TYPE MODELS ABUA30TLAV ABUA36TLAV INDOOR UNITS INDOOR UNITS 05 11 ...

Page 221: ...WALL MOUNTED TYPE MODELS ASUA7TLAV ASUA9TLAV ASUA12TLAV ASUA14TLAV 05 12 ...

Page 222: ...MODELS ASUB18TLAV ASUB24TLAV 05 13 ...

Page 224: ...MODEL UTP RU01AH MODEL UTP RU01BH 5 2 3 RB Unit 05 15 ...

Page 225: ...MODEL UTP RU01CH 05 16 ...

Page 226: ...MODEL UTP RU04BH 05 17 ...

Page 227: ...MODELS AAUA48TLAV 5 2 4 Outdoor Air Unit 05 18 MODELS AAUA72TLAV ...

Page 228: ...MODELS AAUA96TLAV 05 19 ...

Page 230: ...6 DISASSEMBLY PROCESS ...

Page 245: ......