En-18

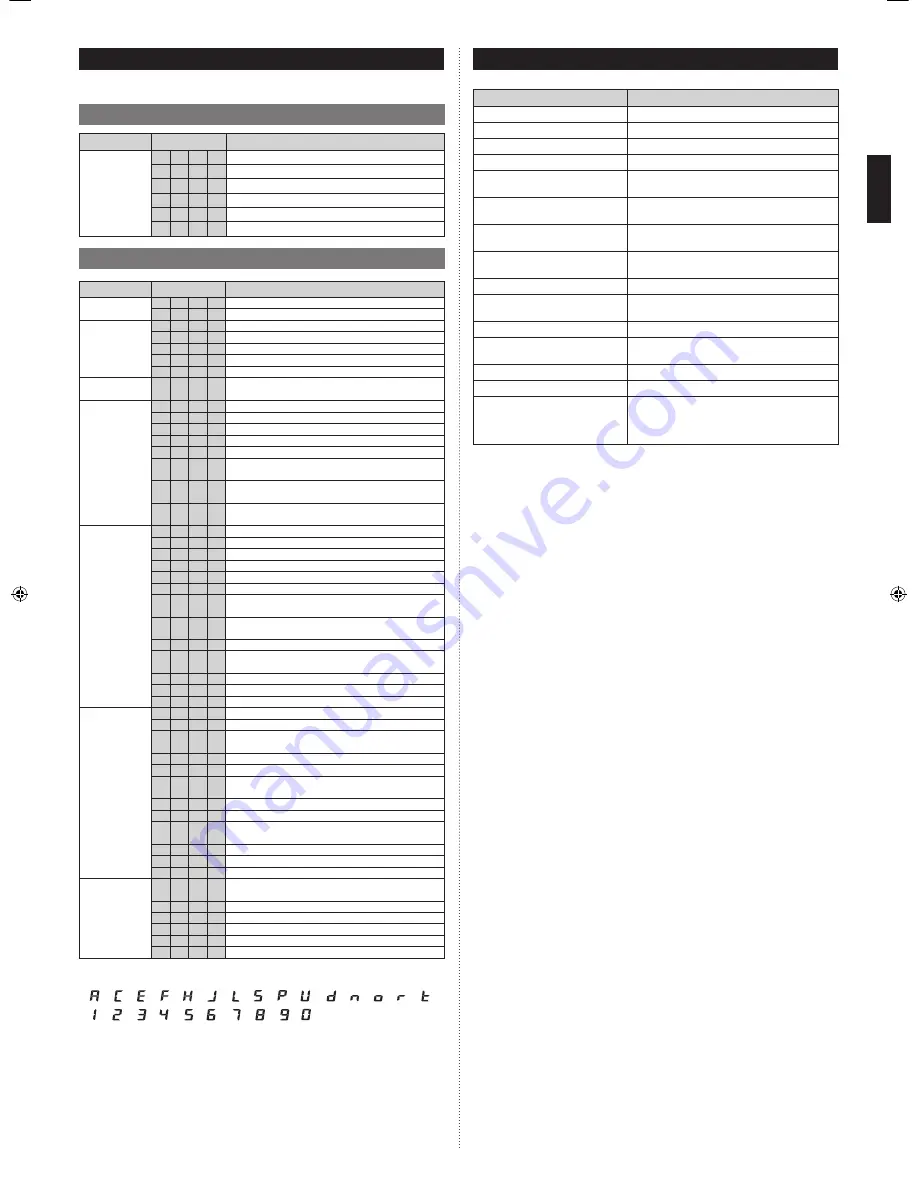

10. LED STATUS

You can determine the operating status by the lighting up and blinking of the LED display.

Check the status using the table below.

10.1. Normal operation codes

Mode

CODE

DESCRIPTION

Operation

C

L

Cooling

H

t

Heating

o

r

During oil recovery operation

d

F

During defrosting operation

P

C

During power saving operation

L

n

During low noise operation

10.2. Error codes

Mode

CODE

DESCRIPTION

Communication

error

E

1

4.

2 Outdoor unit network communication 2 error

E

1

4.

5 The number of indoor unit shortage

Function setting

error

E

2

2.

1 Indoor unit capacity error

E

2

4.

2 Connection unit number error (Indoor unit)

E

2

6.

1 Indoor unit duplicate address error

E

2

8.

1 Auto address setting error

E

2

8.

4 Signal amplifier auto address error

Indoor unit

actuator error

E

5

U.

1 Indoor unit miscellaneous error

Outdoor unit

PCB/Electrical

component/

Switch error

E

6

1.

5 Outdoor unit reverse/missing phase & wiring error

E

6

2.

3 Outdoor unit EEPROM access error

E

6

2.

6 Outdoor unit inverters communication error

E

6

2.

8 Outdoor unit EEPROM data corruption error

E

6

3.

1 Outdoor unit inverter error

E

6

7.

2

Outdoor unit inverter PCB power short interruption

error

E

6

8.

2

Outdoor unit rush current limiting resister temp. rise

error (protective operation)

E

6

9.

1

Outdoor unit transmission PCB parallel communica-

tion error

Outdoor unit

sensor error

E

7

1.

1 Outdoor unit discharge temp. thermistor 1 error

E

7

2.

1 Outdoor unit compressor temp. thermistor 1 error

E

7

3.

3 Outdoor unit heat ex. liquid temp. thermistor error

E

7

4.

1 Outside air temp. thermistor error

E

7

5.

1 Outdoor unit suction gas temp. thermistor error

E

7

7.

1 Outdoor unit heat sink temp. thermistor error

E

8

2.

1

Outdoor unit sub-cool heat ex. gas inlet temp.

thermistor error

E

8

2.

2

Outdoor unit sub-cool heat ex. gas outlet temp.

thermistor error

E

8

3.

2 Outdoor unit liquid pipe temp. thermistor 2 error

E

8

4.

1

Outdoor unit current sensor 1 error

(permanent stop)

E

8

6.

1 Outdoor unit discharge pressure sensor error

E

8

6.

3 Outdoor unit suction pressure sensor error

E

8

6.

4 Outdoor unit high pressure switch 1 error

Outdoor unit

actuator error

E

9

3.

1 Outdoor unit inverter compressor start up error

E

9

4.

1 Outdoor unit trip detection

E

9

5.

5

Outdoor unit compressor motor loss of synchroniza-

tion

E

9

7.

1 Outdoor unit fan motor 1 lock error

E

9

7.

4 Outdoor unit fan motor 1 undervoltage error

E

9

7.

5

Outdoor unit fan motor 1 temperature error

(protective action)

E

9

7.

9 Outdoor unit fan motor 1 driver error.

E

9

8.

1 Outdoor unit fan motor 2 lock error

E

9

8.

5

Outdoor unit fan motor 2 temperature error

(protective action)

E

9

8.

9 Outdoor unit fan motor 2 driver error.

E

9

A.

1 Outdoor unit coil 1 (expansion valve 1) error

E

9

A.

2 Outdoor unit coil 2 (expansion valve 2) error

Refrigerant

system error

E

A

1.

1

Outdoor unit discharge temperature 1 error (perma-

nent stop)

E

A

3.

1 Outdoor unit compressor 1 temperature error

E

A

4.

1 Outdoor unit high pressure error

E

A

4.

2 Outdoor unit high pressure protective action 1

E

A

5.

1 Outdoor unit low pressure error

E

A

C.

4 Outdoor unit heat sink temperature error

,,

,

,

,

,

,

,

,

,

,

t:

L:

7:

H:

J:

6:

A:

C:

E:

F:

,

,

,

d:

n:

o:

r:

,

,

,

,

,

9:

P:

U:

S:

8:

,

,

,

,

5:

3:

4:

1:

2:

,

0:

7 segment LED indicator:

11. INFORMATION

Main contents of label

Item

Detail

1. Model name

Model name

2. Serial number

Serial number

3. Electric characteristics

Phase, rated voltage, and frequency

4. Weight

Product

weight

5. Capacity

Cooling/heating capacity under cooling/heating

condition (refer to item 15)

6. Current

Electric current during cooling/heating operation

under cooling/heating condition (refer to item 15)

7. Input

power

Input during cooling/heating operation under cool-

ing/heating condition (refer to item 15)

8. Max.

Current

Maximum electric current

(Test condition: IEC60335-2-40)

9. Refrigerant

Refrigerant type and initial charging amount

10. Max. pressure (HP/LP)

Means pressure of High Pressure side/Low Pres-

sure side

11. Protection

Protection level against dust and water

12. Condition of cooling/heating

Dry-bulb temperature and wet-bulb temperature

under standard cooling/heating condition

13. Manufacture year

Manufacture year

14. Origin

Origin country

15. Manufacturer

Manufacturer

FUJITSU GENERAL LIMITED

Address: 3-3-17, Suenaga, Takatsu-ku, Kawasaki

213-8502, Japan

9380545200-03_IM.indb 18

9380545200-03_IM.indb 18

4/6/2017 3:20:35 PM

4/6/2017 3:20:35 PM