En-7

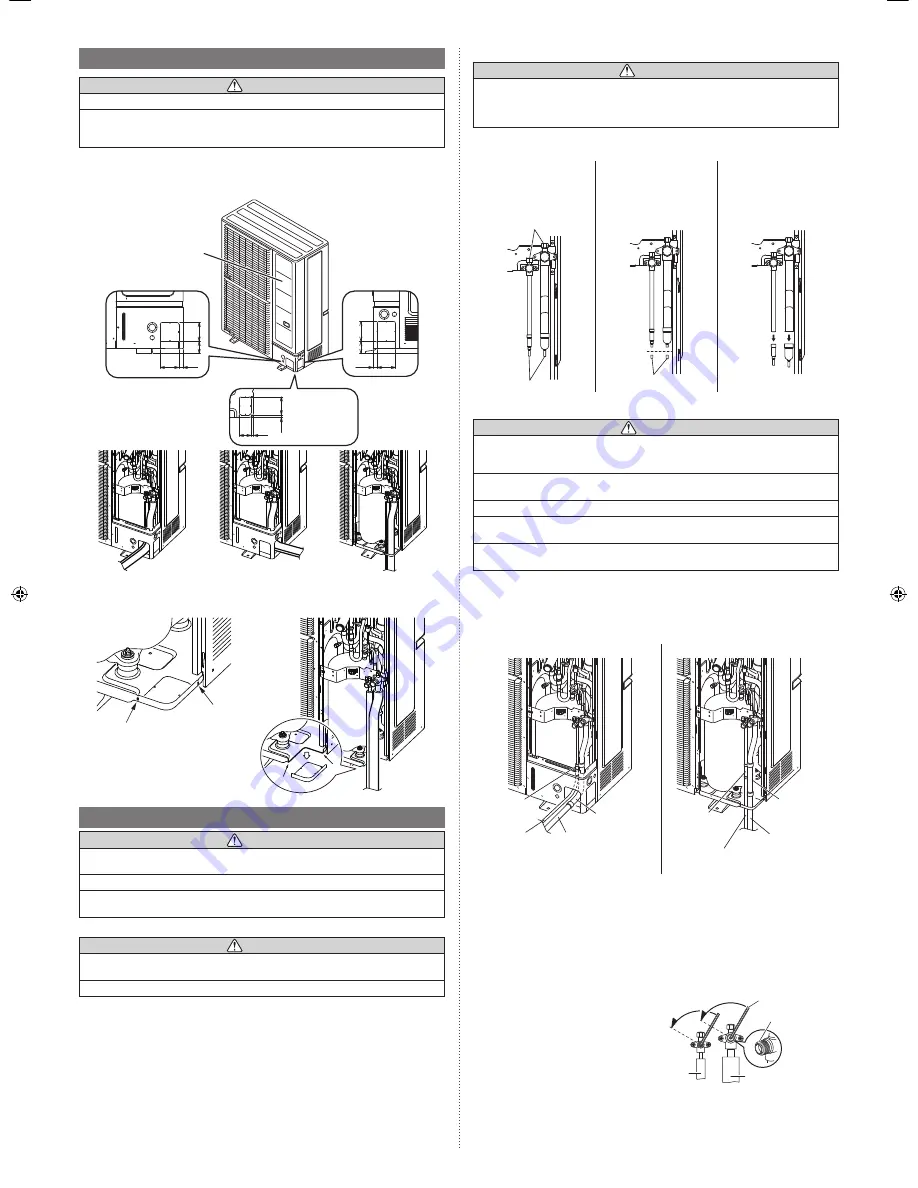

5.4.2 Removing the pinch pipe

WARNING

Remove the pinch pipe only when the internal gas is completely drained as shown on

the below instructions.

If gas still remains inside, the piping may crack if you melt the brazing filler metal of the

junction area with a burner.

Before connecting the piping, remove the pinch pipe in accordance with the following

instructions:

1) Verify that the liquid

side and gas side 3-way

valves are closed.

2) Cut the end of the liquid

side and gas side pinch

pipe and vent the gas

inside the pinch pipe.

3) After all the gas is vented,

melt the brazing filler

metal on connecting part

using a torch and remove

the pinch pipe.

3-way valves

Pinch pipes

End of pinch pipes

5.4.3 Pipe connection

CAUTION

Seal the pipe route hole with putty (locally purchased) such that there are no gaps.

Small insects or animals that are trapped in the outdoor unit may cause a short circuit in

the electrical component box.

To prevent pipe damage; do not make sharp bends.

Bend the pipe at a radius of 70 mm or greater.

Do not bent pipe many times at same part to prevent break.

After completing all the pipe connection by brazing, perform the indoor unit pipe connec-

tion with a flare joint.

When removing the pinch pipe or brazing the joint pipe, carry out the work while cooling

down the 3-way valve sufficiently.

• Braze the joint pipe onto the 3-way valves at the liquid and gas side. Install the joint pipe

appropriately so that it can be connected easily with the main pipe.

• Braze the joint pipe at the liquid and gas side with the main pipe.

* Be sure to supply nitrogen when brazing.

Connection example

Front connection

Bottom connection

Liquid pipe

(locally

purchased)

Gas pipe

(locally

purchased)

Joint pipe A

(accessory) *1

Joint pipe C

(accessory) *2

Liquid pipe

(locally purchased)

Gas pipe

(locally

purchased)

Joint pipe B

(accessory) *1

Joint pipe C

(accessory) *2

*1: 090/108 model only, *2: 090 model only

5.4.4 Handling precautions for the valves

• Mounted part of Blank cap is sealed for protection.

• Fasten blank cap tightly after opening valves.

Operating the valves

• Use a hexagon wrench (size 3/16 in (4 mm)).

Opening:

(1) Insert the hexagon wrench into the

valve shaft, and turn it counterclock-

wise.

(2) Stop turning when the valve shaft can

no longer be turned. (Open position)

Closing:

(1) Insert the hexagon wrench into the

valve shaft, and turn it clockwise.

(2) Stop turning when the valve shaft can

no longer be turned. (Closed position)

Opening

direction

Hexagon wrench

Seal

(blank

cap

installation

portion)

Liquid

pipe

Gas pipe

Opening

direction

5.3. Opening the knockout hole

CAUTION

Be careful not to deform or scratch the panel while opening the knockout holes.

To protect the piping insulation after opening a knockout hole, remove any burrs from

the edge of the hole. It is recommended to apply rust prevention paint to the edge of the

hole.

• Pipes can be connected from 3 directions, front, lateral side and bottom. (Fig. A)

• When connecting at the bottom, remove the service panel and piping cover on the front

of the outdoor unit, and open the knockout hole provided at the bottom corner of the

piping outlet.

92

21

61

100

94

21

61

94

60 12

14

90

Unit: mm

Fig. A

Service panel

Top view of

the base

Front connection

Lateral connection

Bottom connection

• It can be installed as shown on “Fig. B” cutting out the 2 slits as indicated on “Fig. C”.

(When cutting slits, use a steel saw.)

Slit

Slit

Fig. B

Bottom

connection

Fig. C

5.4. Pipe

connection

CAUTION

Do not use mineral oil on a flared part. Prevent mineral oil from getting into the system

as this would reduce the lifetime of the units.

While brazing the pipes, be sure to blow dry nitrogen gas through them.

The maximum lengths of this product are shown in the table. If the units are further

apart than this, correct operation cannot be guaranteed.

5.4.1 Bending pipes

CAUTION

To prevent breaking of the pipe, avoid sharp bends. Bend the pipe with a radius of

curvature of 4 in (100 mm) or more.

If the pipe is bent repeatedly at the same place, it will break.

• If pipes are shaped by hand, be careful not to collapse them.

• Do not bend the pipes at an angle of more than 90°.

• When pipes are repeatedly bent or stretched, the material will harden, making it difficult

to bend or stretch them any more.

• Do not bend or stretch the pipes more than 3 times.

9380545200-03_IM.indb 7

9380545200-03_IM.indb 7

4/6/2017 3:20:34 PM

4/6/2017 3:20:34 PM