En-17

PIPE INSTALLATION II

8.

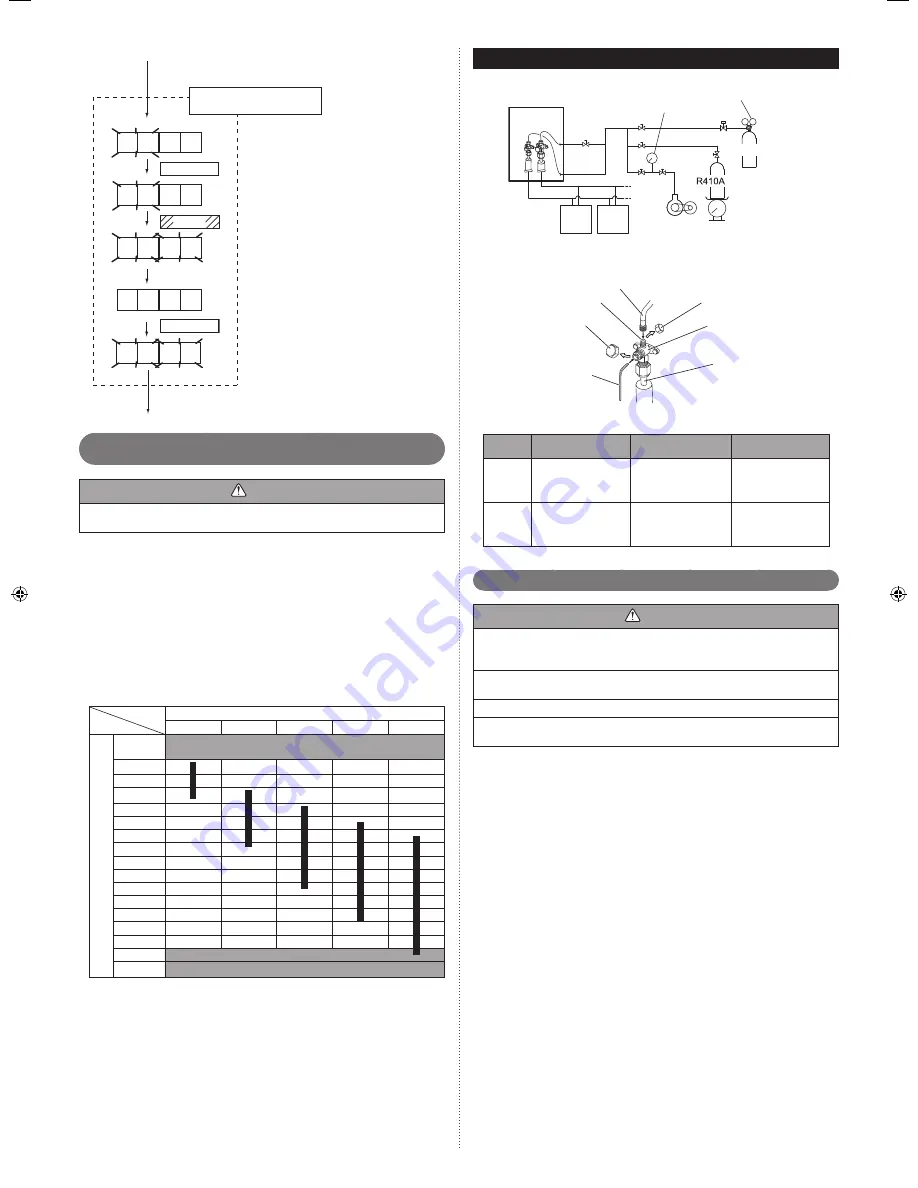

A Connection system

Fig.

Outdoor unit

Pressure gauge

Vacuum

pump

Scale

Pressure regulating valve

Nitrogen

Indoor

unit

Indoor

unit

B

Fig.

Service hose with valve core

Charging port

Charging port cap

3-way valve

Connecting pipe

Blank cap

Hexagon wrench

4mm (5/32")

A

Table.

Pipe

3-way valve

Blank cap

Charging port cap

Liquid

valve

7.0 to 9.0 N·m

(70 to 90 kgf·cm)

20.0 to 25.0 N·m

(200 to 250 kgf·cm)

12.5 to 16.0 N·m

(125 to 160 kgf·cm)

Gas

valve

11.0 to 13.0 N·m

(110 to 130 kgf·cm)

30.0 to 35.0 N·m

(300 to 350 kgf·cm)

12.5 to 16.0 N·m

(125 to 160 kgf·cm)

Sealing test

8. 1.

CAUTION

Use only nitrogen gas.

Never use refrigerant gas, oxygen, in

fl

ammable gas or poisonous gas to pressurize

the system. (If oxygen is used, there is the danger of an explosion.)

Do not apply shock during sealing test.

It can rupture the pipes and cause serious injury.

Do not turn on the power unless all operations are complete.

Do not block the walls and the ceiling until the sealing test and the charging of the

refrigerant gas have been completed.

After connecting the pipes, perform an sealing test.

Recheck that the 3-way valve are closed before performing a sealing test.

(Fig. B)

Pour nitrogen gas through both the liquid pipe and the gas pipe.

Pressurize nitrogen gas to 4.2 MPa to perform the sealing test.

Check all

fl

are connection areas and brazed areas.

Then, check that the pressure has not decreased.

Compare the pressures after pressurizing and letting it stand for 24 hours, and check

that the pressure has not decreased.

When the outdoor temperature changes 5 °C, the test pressure changes 0.05 MPa.

*

If the pressure has dropped, the pipe joints may be leaking.

If a leakage is found, immediately repair it and perform a sealing test again.

* Decrease the pressure of nitrogen gas before blazing

After completing the sealing test, release the nitrogen gas from both valves.

Release the nitrogen gas slowly.

It may take about 10 minutes for completing

the processing.

End

1

@

@

> >

4

4

ﻸ

ﻮ ﻮ

ﻮ ﻮ

ﻺ ﻶ

First 2 digits Last 2 digits

Press the “SELECT” button until

“11” is displayed.

Press the “ENTER” button for more

than 3 seconds.

Automatic address setting

for indoor units

@

@

The number of indoor units with normal set-

tings will be displayed at the

fi

rst 2 digits of

the 7 segment display. The number of indoor

units with error will be displayed at the last 2

digits.

NOTE) After the “ENTER” button is pressed, the

end processing will occur for about 30 seconds.

During this period, the 7 segment will blink.

ENTER

SELECT

ENTER

Resistance measurement of transmission cable

7. 7.

(Measure with breaker OFF)

CAUTION

Do not turn on the power if the resistance between the terminals of the transmission

cable is abnormal. Otherwise, the PC board may be damaged.

Measure the resistance between 2 terminals of a transmission cable.

Transmission cable connecting indoor units, outdoor units, and signal ampli-

(1)

fi

ers

Measure the resistance of the signal ampli

fi

er terminal and the terminal of the indoor

and outdoor units connected farthest away from the device where terminal resistor

is measured.

A value from the table is displayed, depending on the distance from the signal ampli-

fi

er and the device where the terminal resistor is set.

This value is an estimate.

Transmission cable connecting outdoor units in a refrigerant system

(2)

The resistance between the terminals of the transmission cable is 45-60

Ω

.

This value is an estimate.

Distance from termination resistor (m)

0 ~100

~ 200

~ 300

~400

~500

Approximate resistance (

Ω

)

0 ~ 50

A short circuit somewhere or 2 or more termination resistors are

connected

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190 ~

Faulty contact or wiring length over 500 m

1K ~

∞

Faulty contact, open circuit, or no termination resistor

9380545026-02_IM.indb 17

9380545026-02_IM.indb 17

19/08/2013 17:20:09

19/08/2013 17:20:09