14

INDOOR UNIT

FACTORY

PISTON

SEER RATING

OD UNIT

NOMINAL

TONS

REFRIGERANT

ORIFICE

SIZE

13

1.5

R410a 0.047

14

1.5 R410a 0.049

(-)F1P1821SPAN

0.047

13

1.5

R22

0.049

12

1.5

R22

0.051

10

1.5

R22

0.053

13

2

R410a 0.053

14

2 R410a 0.057

(-)F1P2421SPAN

0.053

13

2

R22

0.057

12

2

R22

0.061

10

2

R22

0.063

13

2.5

R410a 0.061

14

2.5 R410a 0.063

(-)F1P3024SPAN

0.061

13

2.5

R22

0.065

12

2.5

R22

0.065

10

2.5

R22

0.065

13

3

R410a 0.065

14

3 R410a 0.068

(-)F1P3624SPAN

0.065

13

3

R22

0.069

12

3

R22

0.070

10

3

R22

0.070

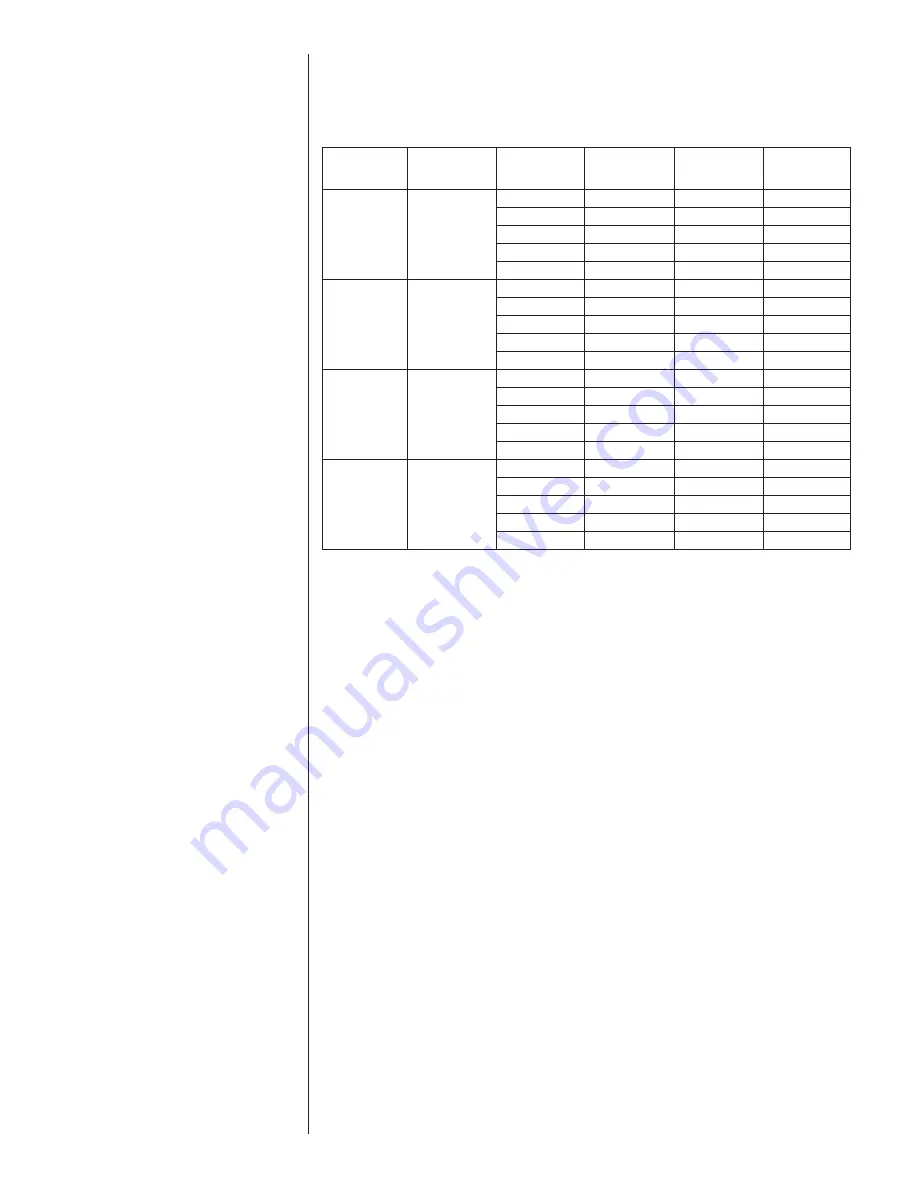

3.8 ORIFICE SIZE: (-)F1P*****P MODELS

(-)F1P*****P air-handlers are equipped with a fixed orifice (piston) sized for a typical 13

SEER R-410A outdoor unit. The piston must be changed if the outdoor unit has a higher

or lower efficiency or if the system is using R-22 as a refrigerant. The chart below shows

recommended orifice sizes for various efficiencies for R-410A and R-22.

The orifice is located in the indoor coil distributor body and can be accessed by

unscrewing the distributor body. Replacing the Teflon gasket is recommended when

changing the orifice to assure a leak free joint. Orifices and gaskets are available from

most local wholesale distributors.

3.9 REFRIGERANT LINE CONNECTIONS & CHARGING

3.9.1 PREPARATION

The coil is shipped with a low pressure (5-10 psig) charge of dry nitrogen which will be

released when the rubber plugs are removed. Leave the rubber plugs in the refrigerant

connection stubs on the air-handler until the refrigerant lines are ready to be brazed to

the refrigerant connection stubs to prevent contaminants from entering the coil. Clean

the ends of the tubing and coil connection stubs (inside and outside) with an alcohol

wipe before inserting the line set tubes into the coil connection stubs to assure a quality

leak-free braze joint.

Refer to the outdoor unit installation instructions for details on refrigerant line sizing and

installation. Be sure to follow long line length guidelines if they apply.

Route the refrigerant tubing in a manner than does not block service access to the front

of the air-handler.

3.9.2 LIQUID LINE FILTER DRIER

A new liquid filter drier must be installed every time any part of the system has been

open to the atmosphere, even if it’s for a short period of time. The filter drier should be

installed close to the air-handler for a system started up in the cooling mode and near

the outdoor unit for a heat pump system started up in the heating mode. This allows the

filter drier to catch any contaminants in the liquid line before they can enter the indoor or

outdoor TXV or piston inlet screen.

3.9.3 BRAZING

Air inside the tubing and coil should be displaced with dry nitrogen prior to the brazing

process to prevent the formation of harmful copper oxide inside the tubing. It is very

important not to pressurize the system with nitrogen while brazing or pin-hole leaks will

form in the braze joint. This is accomplished by removing the gauge port valve core on

one of the outdoor unit service valves to allow the pressure to be relieved as the heat-

ed nitrogen expands. Fill the system with dry nitrogen through the other service valve

gauge port and then turn the nitrogen flow off just before brazing is begun.