Chapter 2 How to Load Documents

51

Conditions for Mixed Batch Scanning

The following conditions apply when scanning a mixed batch

of documents with different paper weights/friction coefficients/

sizes.

Make sure to test a few sheets first to check if the documents

can be scanned.

For details, refer to

"Documents with Different Widths" (page

Paper direction

Align the direction of the paper fiber with the feed direction.

Paper weight

The following paper weights can be used:

27 to 413 g/m

2

(7.2 to 110 lb)

Friction coefficient

It is recommended to use the same type of paper from the same

manufacturer.

When papers of different manufacturers/brands are mixed, it affects the

feeding performance as the difference in the friction coefficient

increases.

The following friction coefficients are recommended:

0.35 to 0.60 (reference value for paper friction coefficient)

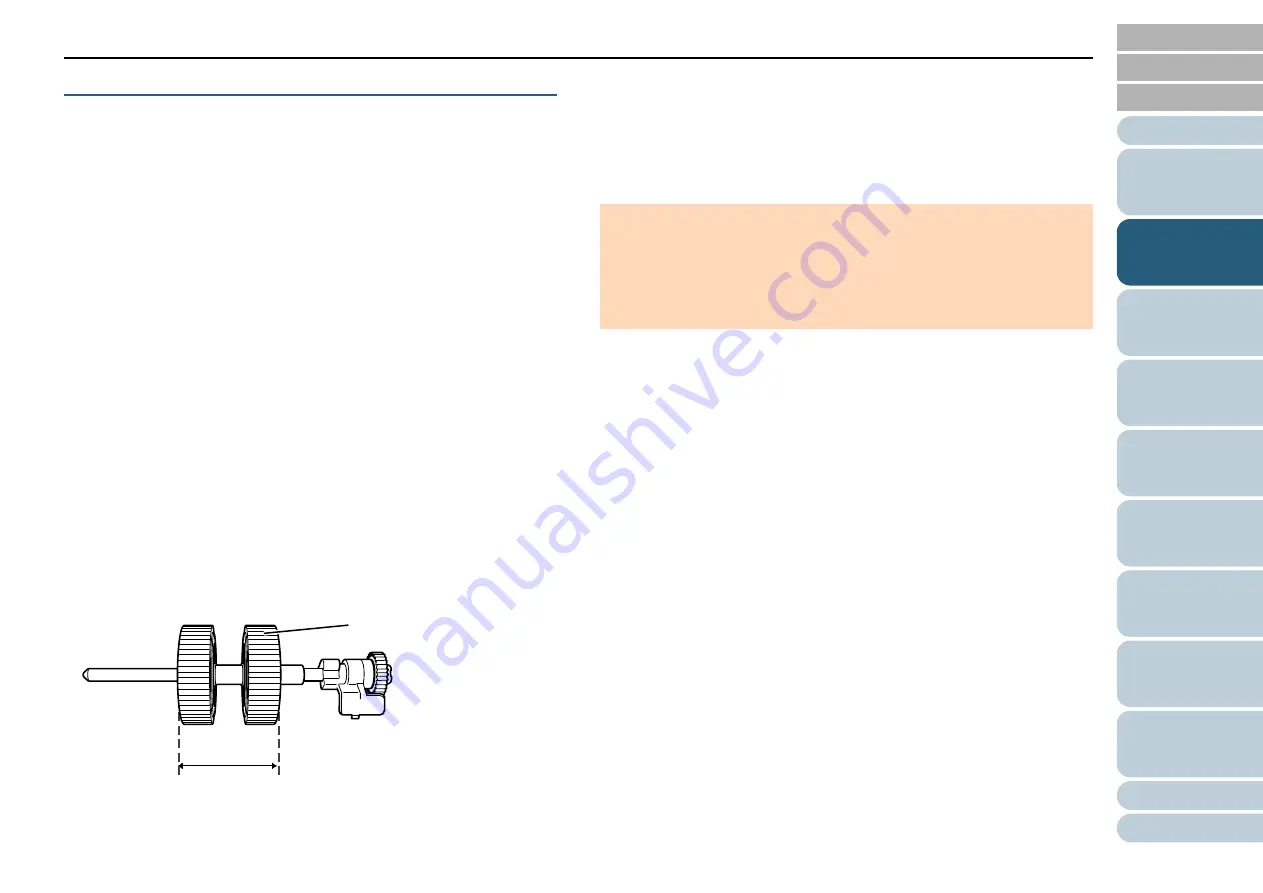

Document position

Use paper sizes that fit the 39 mm width of the pick roller in the center.

Paper size

When you scan a mixed batch with different sizes, not feeding the

documents straight may cause troubles such as paper jams or part of

the image to appear missing.

It is recommended to check the documents thoroughly before scanning

and also check the image if the document was skewed.

Documents that cannot be scanned in a mixed batch

The following types of documents cannot be mixed in the same batch:

z

Carbonless paper

z

Bond paper

z

Perforated documents

z

Thermal paper

z

Carbon-backed paper

z

OHP film

z

Tracing paper

39 mm

Pick roller

ATTENTION

z

When scanning a mixed batch with different sizes, documents are

more likely to skew because the side guides do not contact every

sheet.

z

Do not use [Check Length] or [Check Overlapping and Length] for

multifeed detection.