25

The air distribution system has the greatest effect

on airflow. The duct system is totally controlled

by the contractor. For this reason, the contractor

should use only industry-recognized procedures.

The correct air quantity is critical to air conditioning

systems. Proper operation, efficiency, compressor

life, and humidity control depend on the correct

balance between indoor load and outdoor unit

capacity. Excessive indoor airflow increases the

possibility of high humidity problems. Low indoor

airflow reduces total capacity and can cause coil

icing. Serious harm can be done to the compressor

by low airflow, such as that caused by refrigerant

flooding.

Heat pump systems require a specified airflow.

Each ton of cooling requires between 320 and

450 cubic feet of air per minute (CFM). See the

PDQXIDFWXUHU·VVSHFVKHHWIRUUDWHGDLUIORZIRUWKH

system being installed.

Duct design and construction should be carefully

done. System performance can be lowered

dramatically through bad planning or workmanship.

Air supply diffusers must be selected and located

carefully. They must be sized and positioned to

deliver treated air along the perimeter of the space.

If they are too small for their intended airflow, they

become noisy. If they are not located properly, they

cause drafts. Return air grilles must be properly

sized to carry air back to the blower. If they are too

small, they also cause noise.

The installers should balance the air distribution

system to ensure proper quiet airflow to all rooms in

the home. This ensures a comfortable living space.

These simple mathematical formulas can be used

to determine the CFM in a residential or light

commercial system.

Electric resistance heaters can use:

CFM = volts × amps × 3.413

SHC × temp rise

Gas furnaces can use:

CFM = Output Capacity in BTUH*

SHC × temp rise

*Refer to furnace data plate for furnace output capacity.

SHC = Sensible Heat Constant (see table below)

An air velocity meter or airflow hood can give a

more accurate reading of the system CFM.

The measurement for temperature rise should

be performed at the indoor coil inlet and near the

outlet, but out of direct line of sight of the heater

element or heat exchanger. For best results,

measure air temperature at multiple points and

average the measurements to obtain coil inlet and

outlet temperatures.

Star

t-Up

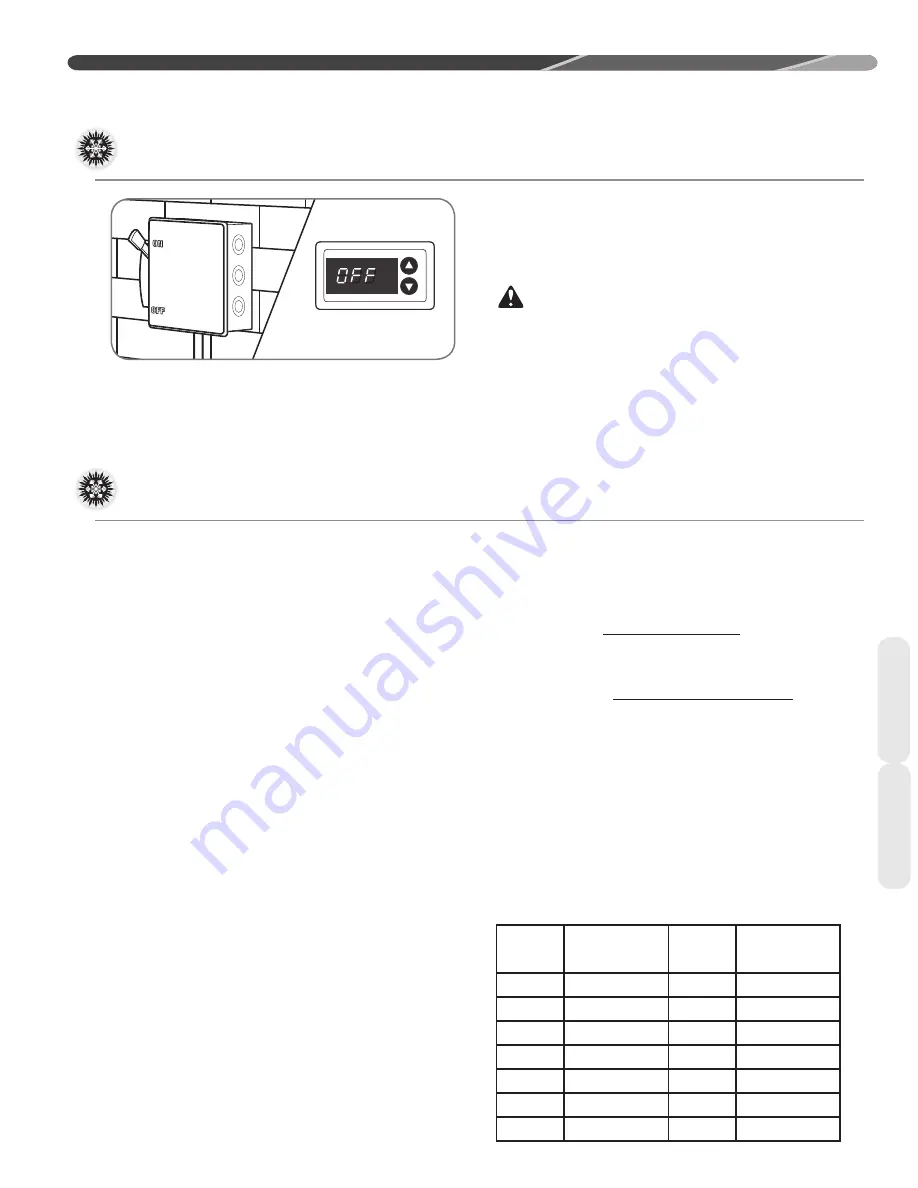

At initial start-up or after extended shutdown

periods, make sure the crankcase heater is

energized for at least 12 hours before the

compressor is started. (Disconnect switch is

on and wall thermostat is off.)

Even though the unit is factory-charged with

Refrigerant-410A, the charge must be checked

to the charge table attached to the service panel

and adjusted, if required. Allow a minimum of

15 minutes of run time before analyzing charge.

CAUTION:

Single-pole contactors

are used on all standard single-phase units

through 5 tons. Caution must be exercised when

servicing as only one leg of the power supply is

broken by the contactor.

9ajÛg

o

ALTITUDE

(FEET)

SENSIBLE HEAT

CONSTANT

(SHC)

ALTITUDE

(FEET)

SENSIBLE HEAT

CONSTANT

(SHC)

Sea Level

1.08

6000

0.87

500

1.07

7000

0.84

1000

1.05

8000

0.81

2000

1.01

9000

0.78

3000

0.97

10000

0.75

4000

0.94

15000

0.61

5000

0.90

20000

0.50

START-UP

Start-Up

Checking Airflow