Summary of Contents for M3099EH

Page 1: ...M3099EX EH IMAGE SCANNER OEM MANUAL C150 E047 02EN ...

Page 2: ...M3099EX EH IMAGE SCANNER OEM MANUAL ...

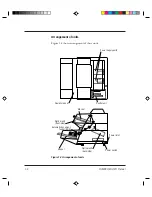

Page 15: ...M3099EX EH OEM Manual 1 3 OVERVIEW Figure 1 2 1000 sheets hopper type ...

Page 170: ...4 40 M3099EX EH OEM Manual ...

Page 176: ...5 6 M3099EX EH OEM Manual ...

Page 196: ...8 10 M3099EX EH OEM Manual ...

Page 216: ...M3099EX EH OEM Manual B 14 ...

Page 226: ...IN 4 M3099EX EH OEM Manual ...

Page 228: ......