4.1 Mounting Requirements

C141-E234

4-5

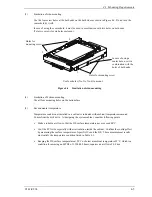

(3)

Limitation of side-mounting

Use the four screw holes at the both ends on the both sides as shown in Figure 4.4. Do not use the

center hole by itself.

In case of using the center hole, it must be used in combination with two holes on both ends.

(Total six screws for six holes enclosed)

Holes for

mounting screw

1

2

3

4

In case of using a

center hole, use it in

combination with the

holes of both ends.

Holes for mounting screw

Use four holes (No.1 to No.4) to mount.

Figure 4.4

Limitation of side-mounting

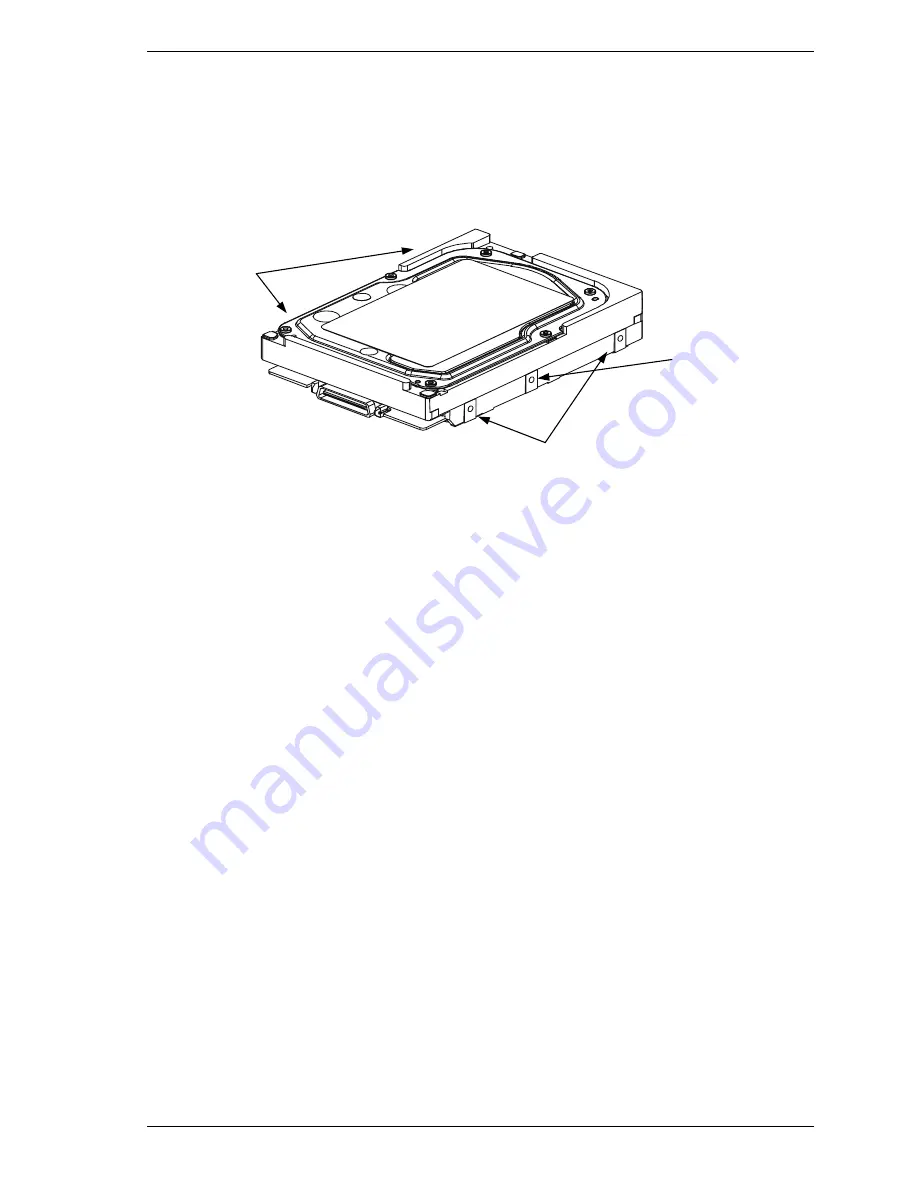

(4)

Limitation of bottom-mounting

Use all four mounting holes on the bottom face.

(5) Environmental

temperature

Temperature condition at installed in a cabinet is indicated with ambient temperature measured

30 mm from the disk drive. At designing the system cabinet, consider following points.

•

Make a suitable air flow so that the DE surface temperature never exceed 60°C.

•

Cool the PCA side especially with air circulation inside the cabinet. Confirm the cooling effect

by measuring the surface temperature of specific ICs and the DE. These measurement results

must satisfy the temperature condition listed in Table 4.1.

•

Keeping the DE surface temperature at 50

°

C or below at ambient temperature 25

°

C, which is a

condition for assuring an MTBF of 1,200,000 hours, requires an air flow of 0.8 m/s.

Summary of Contents for MAX3036FC

Page 1: ...C141 E234 01EN MAX3147FC MAX3073FC MAX3036FC HARD DISK DRIVES PRODUCT MAINTENANCE MANUAL ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...This page is intentionally left blank ...

Page 16: ...This page is intentionally left blank ...

Page 22: ...This page is intentionally left blank ...

Page 30: ...This page is intentionally left blank ...

Page 38: ...This page is intentionally left blank ...

Page 94: ...This page is intentionally left blank ...

Page 108: ...This page is intentionally left blank ...

Page 110: ...This page is intentionally left blank ...

Page 111: ......

Page 112: ......