64

Operating manual

TX300

S4

Connecting devices to the server

Hardware installation

4.4

Connecting devices to the server

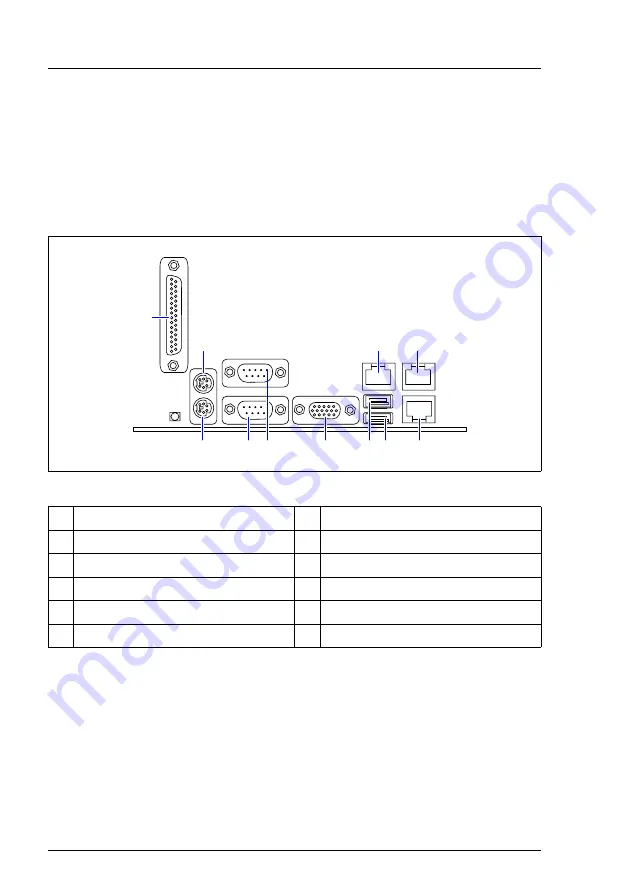

The ports for external devices are on the rear of the server. The additional ports

available on your server depend on the expansion cards installed.

The standard ports (figure

) are marked with symbols, and some are colour-

coded.

Figure 19: Connector panel on the back (floorstand and rack models)

1

Parallel port (optional)

7

USB port 4

2

PS/2 mouse port

8

Monitor port

3

Service LAN port

9

Serial port COM2

4

LAN port 2

10 Serial port COM1 *

5

LAN port 1

11 PS/2 keyboard port

6

USB port 3

*

The serial interface COM1 can be used as the standard interface or for

communication with iRMC.

6

5

8

7

10

9

11

3

4

1

2