En-4

If children under 10 years old may approach the unit, take preventive measures so

that they cannot reach the unit.

Take precautions to prevent the unit from falling.

(1) Install the DX-kit on a place having a suf

fi

cient strength so that it withstands against

the weight of the DX-kit.

(2) Leave the space required to service the DX-kit.

(3) Install the unit where connection to the outdoor unit (or RB unit) is easy.

(4) Install the unit where the connection pipe can be easily installed.

(5) Install the unit where noise and vibrations are not ampli

fi

ed.

(6) Take servicing, etc., into consideration and leave the spaces.

(7) Do not install the unit where it will be exposed to direct sunlight.

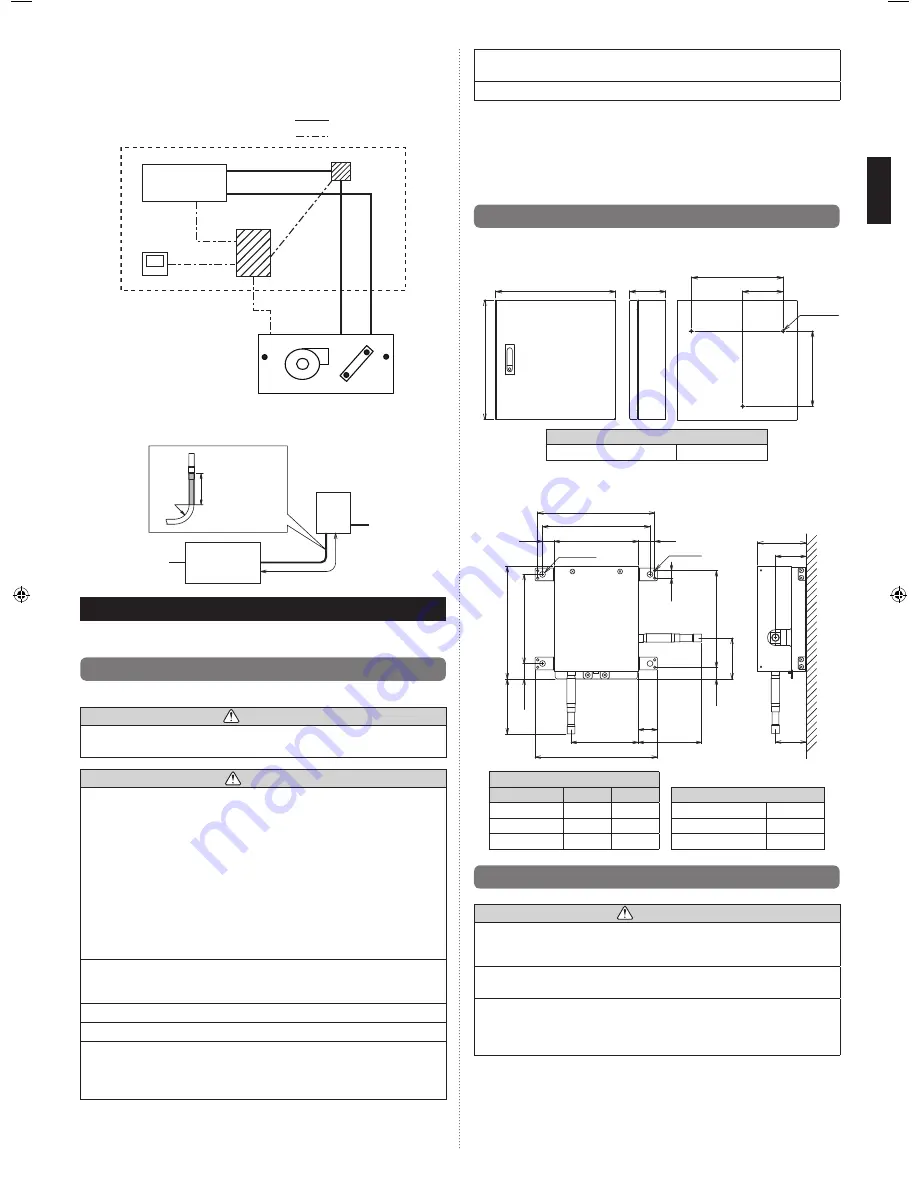

4.2. Installation dimensions

4.2.1. Control unit

400

120

134

306

3 × Ø10

(Unit: mm)

400

251

Weight of the Control unit (kg)

UTY-VDGX

10

4.2.2. EEV unit

EEV unit Dimensions

221

203

159

4 × Ø11

8 × Ø5

22

31

90

58

58

(120)

(127)

168

212.4

(104)

29.2

182

14

22.2

(78)

231

A

B

36

(Unit: mm)

Connection pipe diameter (mm)

Model

A

B

Weight of the EEV unit (kg)

UTP-VX30A

9.52

9.52

UTP-VX30A

2

UTP-VX60A

9.52

9.52

UTP-VX60A

2

UTP-VX90A

12.7

12.7

UTP-VX90A

2

4.3. Installing the unit

WARNING

Install the DX-kit in a location which can withstand a load of at least 5 times the weight

of the main unit and which will not amplify sound or vibration. If the installation location

is not strong enough, the DX-kit may fall and cause injuries.

If the job is done with the panel frame only, there is a risk that the unit will come loose.

Please take care.

Carrying in and installation of the unit should be performed by a suf

fi

cient number

of people and with suf

fi

cient equipment that is adequate for the weight of the unit.

Performing such work by an insufficient number of people or with inadequate

equipment could result in dropping of the unit or personal injury.

(2) Pattern 2

Fujitsu general remote controllers and control devices directly control Fujitsu general out-

door units and indoor units (refrigerant cycle devices, etc.) not manufactured by Fujitsu

general. A system con

fi

guration example is shown below.

System Con

fi

guration Diagram

Fujitsu general-approved devices

Outdoor unit

Indoor unit

Control unit

Liquid pipe

Gas pipe

Control line

Thermistor × 4

Wired remote

controller

Piping

Wiring

EEV unit

3.2.3. Pipe Conditions

EEV

unit

Heat

Exchanger

R

Straight pipe =

200 mm or more

Liquid pipe

Gas pipe

4. INSTALLATION WORK

Correct initial installation location is important because it is dif

fi

cult to move unit after it is

installed.

4.1. Selecting an installation location

Decide the mounting position together with the customer as follows.

WARNING

Select installation locations that can properly support the weight of the DX-kit. Install

the units securely so that they do not topple or fall.

CAUTION

Do not install the DX-kit in the following areas:

• Area with high salt content, such as at the seaside. It will deteriorate metal parts,

causing the parts to fail or the unit to leak water.

• Area

fi

lled with mineral oil or containing a large amount of splashed oil or steam,

such as a kitchen. It will deteriorate plastic parts, causing the parts to fail or the unit

to leak water.

• Area that generates substances that adversely affect the equipment, such as sulfuric

gas, chlorine gas, acid, or alkali. It will cause the copper pipes and brazed joints to

corrode, which can cause refrigerant leakage.

• Area that can cause combustible gas to leak, contains suspended carbon

fi

bers or

fl

ammable dust, or volatile in

fl

ammables such as paint thinner or gasoline. If gas

leaks and settles around the unit, it can cause a

fi

re.

• Area where animals may urinate on the unit or ammonia may be generated.

Do not use the unit for special purposes, such as storing food, raising animals,

growing plants, or preserving precision devices or art objects.

It can degrade the quality of the preserved or stored objects.

Do not install where there is the danger of combustible gas leakage.

Do not install the unit near a source of heat, steam, or

fl

ammable gas.

Install the DX-kit, power supply cable, transmission cable, and remote controller cable

at least 1 m away from a television or radio receivers. The purpose of this is to prevent

TV reception interference or radio noise. (Even if they are installed more than 1 m

apart, you could still receive noise under some signal conditions.)

9381279005_IM.indb 4

9381279005_IM.indb 4

6/30/2014 11:31:17 AM

6/30/2014 11:31:17 AM