En-5

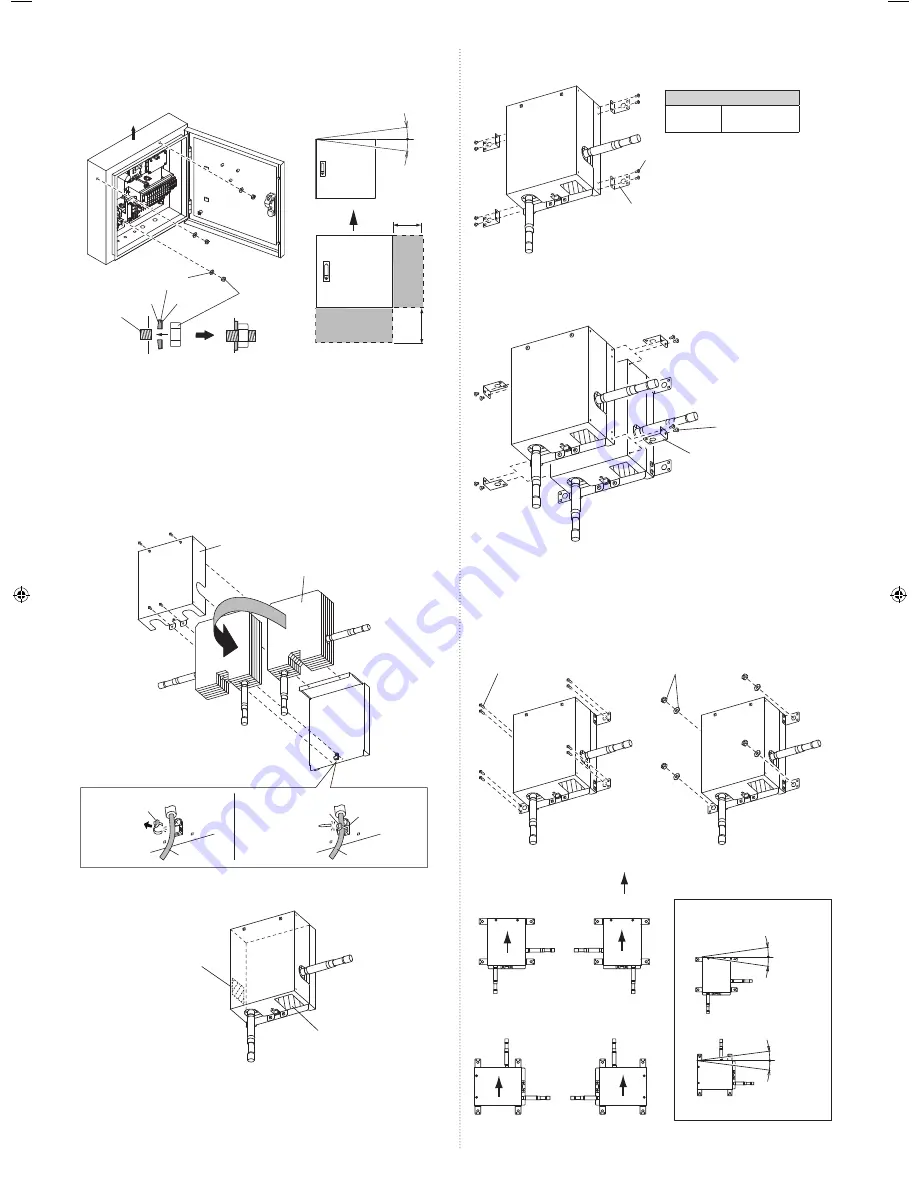

4.3.2.3. Mounting Secure Fittings (If Using 1 EEV unit)

(1) Use the 8 screws (accessories) to secure the secure

fi

ttings (accessories).

Secure

fi

tting (Accessories)

Screws M4×L10 (Accessories)

Tightening torque

M4 screw

0.8 to 2.8 Nm

(8 to 28 kgf·cm)

4.3.2.4. Mounting Secure Fittings (If Using 2 EEV units)

(1) If using 2 EEV units, stacking the 2 kits is recommended.

If stacking 2 EEV units, secure using the secure

fi

ttings (accessories) and screws

(accessories).

Secure

fi

tting (Accessories)

Screws M4×L10

(Accessories)

4.3.2.5. Installing EEV units

Mount the EEV unit to the wall.

Select the securing method according to the installation environment.

Method 1: Use the 8 screws (accessories) to secure the unit.

Method 2: Mount the 4 anchor bolts (

fi

eld supply) to the wall, and then secure the unit.

Screws M4×L16

(Accessories)

Method 1

Method 2

Nuts and washers

(Field supply)

Installable EEV unit orientations

A

A

A

A

B

B

B

B

Orient the arrow upwards

Installable both indoors and outdoors

Installable indoors only

(Cannot be installed outdoors)

EEV unit inclination limits

±10° or

less

±10° or

less

4.3.1. Installing the Control unit

• If installing outdoors, make sure to orient A upwards.

• Using a template (accessory) is recommended when positioning the holes for mounting

the control unit.

±5° or

less

Inclination limits

Sealing washers

(×3, Accessories)

M8 Nuts

(×3, Accessories)

A

A

Contorl

unit

200 mm or more

Service

space

200 mm or more

Service

space

Rubber inside the washer is contacted

tightly with the Control unit.

anchor

bolt

Rubber

Steel

4.3.2. Installing the EEV unit

4.3.2.1. Changing Pipe Orientation

• EEV unit pipe orientation can be changed according to the installation conditions.

(1) Remove the 4 screws and remove the cover.

(2) Cut the cable tie

fi

xing the cable.

(3) Invert both the pipes and heat insulation.

(4) Pass the cable tie (accessory) through the cable clamp, and

fi

rmly secure the cable,

and then cut any unnecessary part of cable tie.

(5) Use the 4 screws to mount the cover.

Cable

Cable

Cable clamp

Cable tie

Cable tie

(accessory)

(2)

(1), (5)

Cover

Heat insulation

(4)

(3)

4.3.2.2. Pasting Seals to the piping holes

Use the seals (accessories) to cover any unused piping holes.

Seal

(Accessories)

Seal

(Accessories)

9381279005_IM.indb 5

9381279005_IM.indb 5

6/30/2014 11:31:18 AM

6/30/2014 11:31:18 AM