Contents

Control box . . . . . . . . . . . . . . . . . . . 4

Specifications . . . . . . . . . . . . . . . . . . . . . 4

Description. . . . . . . . . . . . . . . . . . . . . . . 5

Operating principle . . . . . . . . . . . . . . . . . . 6

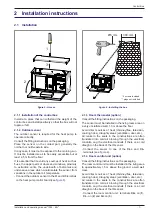

Installation . . . . . . . . . . . . . . . . . . . . . . . 7

Installation of the control box . . . . . . . . . . 7

Outdoor sensor . . . . . . . . . . . . . . . . . 7

Room thermostat (option). . . . . . . . . . . . 7

Room control unit (option) . . . . . . . . . . . 7

DHW sensor (option) . . . . . . . . . . . . . . 8

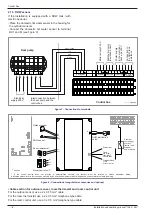

Electrical connections . . . . . . . . . . . . . . . . . 9

Start-up . . . . . . . . . . . . . . . . . . . . . . . 10

Configuring room thermostat . . . . . . . . . . . . 10

Configuring room control unit . . . . . . . . . . . . 10

User interface, room control unit (option)

and room thermostat (option) . . . . . . . . . . . . 12

Setting the slope of heating . . . . . . . . . . . . . 14

Parametering the setting . . . . . . . . . . . . . . 16

General . . . . . . . . . . . . . . . . . . . . 16

Setting parameters . . . . . . . . . . . . . . 16

List of function lines (settings, diagnosis, status) . . 16

Configuring the installation 28

Configuration 1, 2, 5 or 7 : . . . . . . . . . . . . . 29

Faults displayed on the control box . . . . . . . . . 35

Information display . . . . . . . . . . . . . . . . . 35

Before starting-up . . . . . . . . . . . . . . . 36

Starting-up . . . . . . . . . . . . . . . . . . 37

Settings sheet . . . . . . . . . . . . . . . . . . . . 38

Start-up data sheet . . . . . . . . . . . . . . . . . 39

Installation and operating manual "1395 - EN"

- 3 -

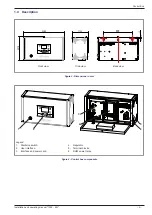

Control Box