- (01-33) -

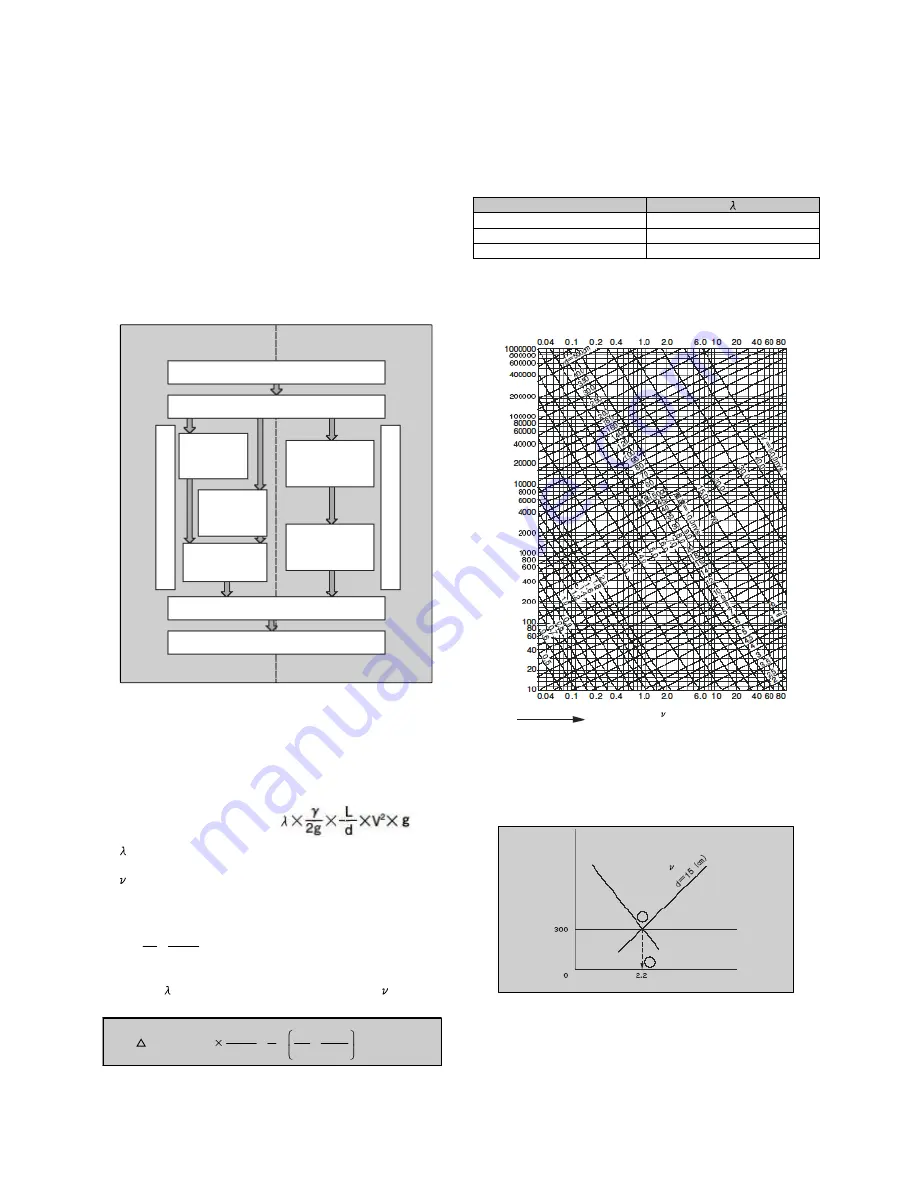

4-6. DUCT DESIGN

4-6-1. CALCULATION OF PRESSURE LOSSES DUE TO VENTILATION

THROUGH DUCT

Ventilation is always conducted through ducts in ventilation

fans for ducts and oven hoods (pressure type). To determine

the ventilation quantity, pressure losses due to the lengths,

the number of bends, and external installation components,

etc., should be accurately calculated, so that proper

ventilation quantities can be determined.

PROCEDURES FROM DUCT

CALCULATION TO MODEL

SELECTION

Equal Pressure Method

Simplified Method

Calculation of Required Ventilation Quantity

Duct Design (Duct Diameter, Duct Type, Piping Route,

Length, Bending)

S

im

pl

ifi

ed

M

et

ho

d

ba

se

d

on

“S

tra

ig

ht

D

uc

t

E

qu

iv

al

en

t L

en

gt

h”

M

et

ho

d

ba

se

d

on

“F

ric

tio

na

l R

es

is

ta

nc

e

D

ia

gr

am

”

To determine

ressure loss in the

straight duct with

“Frictional Resis-

ance Diagram.”

t

t

To determine the “straight

duct equivalent length” for

he entire duct by using the

straight duct equivalent

length table for the

component.

p

To determine the

local pressure loss

with the “local loss

coefficient.”

To determine the intersec-

tion by plotting the “loss

resistance curve” in the

“Static Curve - Quantity

Characteristic Curve.”

To determine the

pressure loss of the

entire duct system.

The required static pressure is determined by adding

10-20% tolerances to the obtained pressure loss.

To select a model satisfying the characteristics with the

“Static Curve - Quantity Characteristic Curve.”

Fig. 7-1

CALCULATION BASED ON

EQUAL PRESSURE METHOD

[1] Circular Duct

(1)

Duct resistance can be calculated from the following formula.

To determine the pressure loss caused in air flowing through

a straight duct (ΔP), the following formula is generally used.

Duct Resistance ΔP (Pa) =

: Friction Coefficient of Duct (0.01 - 0.25)

g: Gravitational Acceleration (9.8m/sec

2

)

: Air Density (kg/m

3

) 1.20kg/m

3

L: Duct Length (m)

d: Duct Diameter (m)

v: Wind Velocity in Duct (m/sec)

v =

3600

π

4

d

Q

2

×

Q: Quantity (Airflow) (m

3

/h)

Where,

= 0.02 (Galvanized Steel Pipe) = 9.8 = 1.2 is

substituted to produce the following.

P (Pa) = 0.02

9.80665

2

3600

π

4

2

d

Q

d

L

9.8

2

1.2

×

×

×

×

×

Friction coefficients of common ducts

(references)

Duct Materials

Aluminum flexible duct

0.03-0.04

PVC pipe

0.01-0.02

Galvanized steel pipe

0.016-0.025

(2) Method based on “Frictional Resistance Chart of Duct”

Frictional Loss Calculation Chart for Circular Ducts

(Part)

<Galvanized Steel Pipe, Internal Roughness ( ε ) = 0.18mm>

Quantity (

Q

, Airflow Volume) [m

3

/h

]

3

Friction Loss Rate ( ) [Pa/m]

Friction Loss Resistance Chart for Galvanized Steel Pipe

Fig. 7-2

<How to Use Chart>

(Conditions)

Ceiling-Mounted Ventilation Fan

Required Ventilation Quantity: 300m

3

/h

Duct Diameter: ø15cm

Duct Length: 5m

Quanti

ty

(Q

, Air

flo

w

Volume)

[m

3

/h

]

3

Fig. 7-3

Wind Velocity ( )

(m/s)

A

Friction Loss Ratio (Pa/m)

B

(1) To determine the intersection (A) of the duct diameter (d)

(15cm) and the quantity of wind running through the duct (Q:

airflow) (300m

3

/h).

(2)

To determine Point (B) by dropping (A) perpendicularly.

(3)

To determine the reading of (B) (2.2 Pa/m in this case), multiply

it with the duct length (5m) to produce 11 Pa.