11

G as c onnection (Fig. 8)

The connection to a gas tank or gas line must be made

by a qualified person in conformity to current updated

UNI-CIG 7129 and 7131 standards after making

sure that the cook top is prepared for the type of gas

available. If not, see: “Adapting to different types of gas”.

Also check that the feed pressure falls within the values

shown in the table: “User characteristics”.

Fig. 8

Metal rigid/semi-rigid h ook-ups

Make the hook-up with metal

fittings and pipes (even

flexible hoses) so as not to stress the components inside

the cook top.

Note: - After installation, use soapy water to check the

perfect seal of the entire connection system.

Important note: make the connection using only metal

fittings and pipes (flexible, continuous-wall steel hoses

or rigid copper or steel tubing) and in such a way that its

entire length can be inspected.

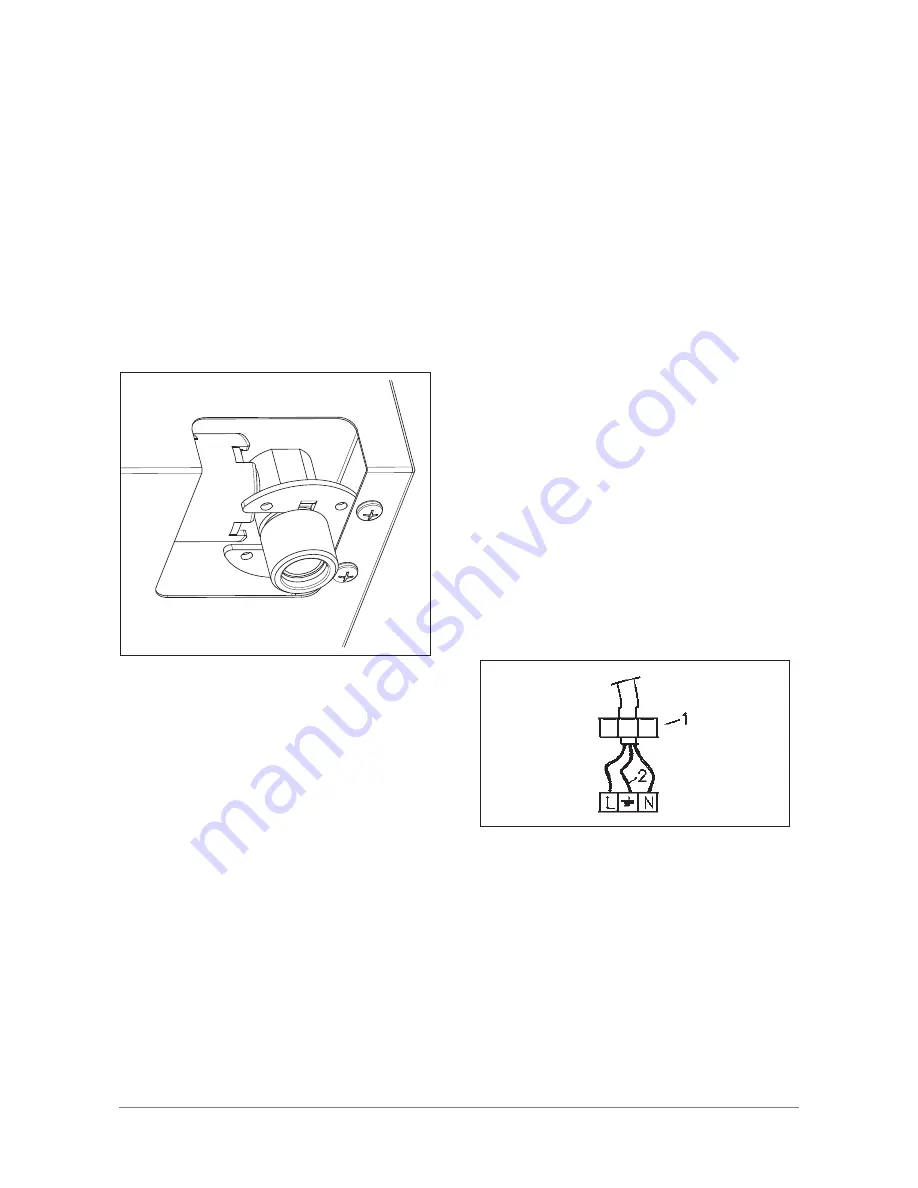

Electrical connection (Fig. 9)

The installer must be

qualified and is responsible for

correct electrical connections and following safety

standards.

Prior to carrying out the electrical connection, please

ensure that:

• the plant characteristics are such as to follow what is

indicated on the matrix plate placed at the bottom of

the working area;

• that the plant is fitted with an efficient earth connection,

following the standards and law provisions in force.

The earth connection is compulsory in terms of the

law.

Should there be no cable and/or plug on the equipment,

use suitable absorption material for the working

temperature as well, as indicated on the matrix

plate. Under no circumstance must the cable reach a

temperature above 50°C of the ambient temperature.

If connecting directly to the mains power supply, fit a

multi-pole switch of a suitable size for the rated capacity

with a clearance distance which completely disconnects

the power line under overvoltage category III conditions,

consistently with the rules of installation (the yellow/

r

o

g

u

l

p

e

h

T

.

)

d

e

t

p

u

r

r

e

t

n

i

e

b

t

o

n

t

s

u

m

e

r

i

w

h

t

r

a

e

n

e

e

r

g

omnipolar switch must be easily reached on the installed

equipment.

Fig. 9

F lexible hose must be certified to AS 1869 class B or D

hose must not be kinked or be able to touch any hot

surface. The supply connection point must be accessible

10mm in diameter and no longer than 1200mm. The

when installed.

The installer must test the operation of the appliance

including gas leakage, ignition and turndown of all

burners. If the appliance cannot be adjusted to perform

correctly refer to the following fault finding table or contact

Kleenmaid: www.kleenmaid-appliances.com.au

Summary of Contents for DG

Page 2: ...2 ...