5/14/2018

Fuling Inverter User Manual - slidepdf.com

http://slidepdf.com/reader/full/fuling-inverter-user-manual

7/54

Chapter 3 Mechanical and Electrical Installation

3. 1

Mechanical Installation

1) Ambient temperature: Ambient temperature influences the inverter life greatly, so it should be within

the range of -10 ~50 .

2) Mount the inverter in a flame retardant s urface and the clearance around the inverter shall be enough

because the inverter will generate lots of heat during runni ng, besides mount the inverter on the base

vertically with screws.

3) Mount in the location where vibration is le ss than 0.6G; the inverter shall be far away from impact ing

lathe.

4) Please do not install the inverter in the place with direct sunlight, high humidit y and water.

5) Mount the inverter in the location free o f corrosive gas, explosive gas or combustible gas.

6) Mount the inverter in the location free of oi l dirt, dust, and metal powder.

1. Installation Environment

2.Installation Location

℃

℃

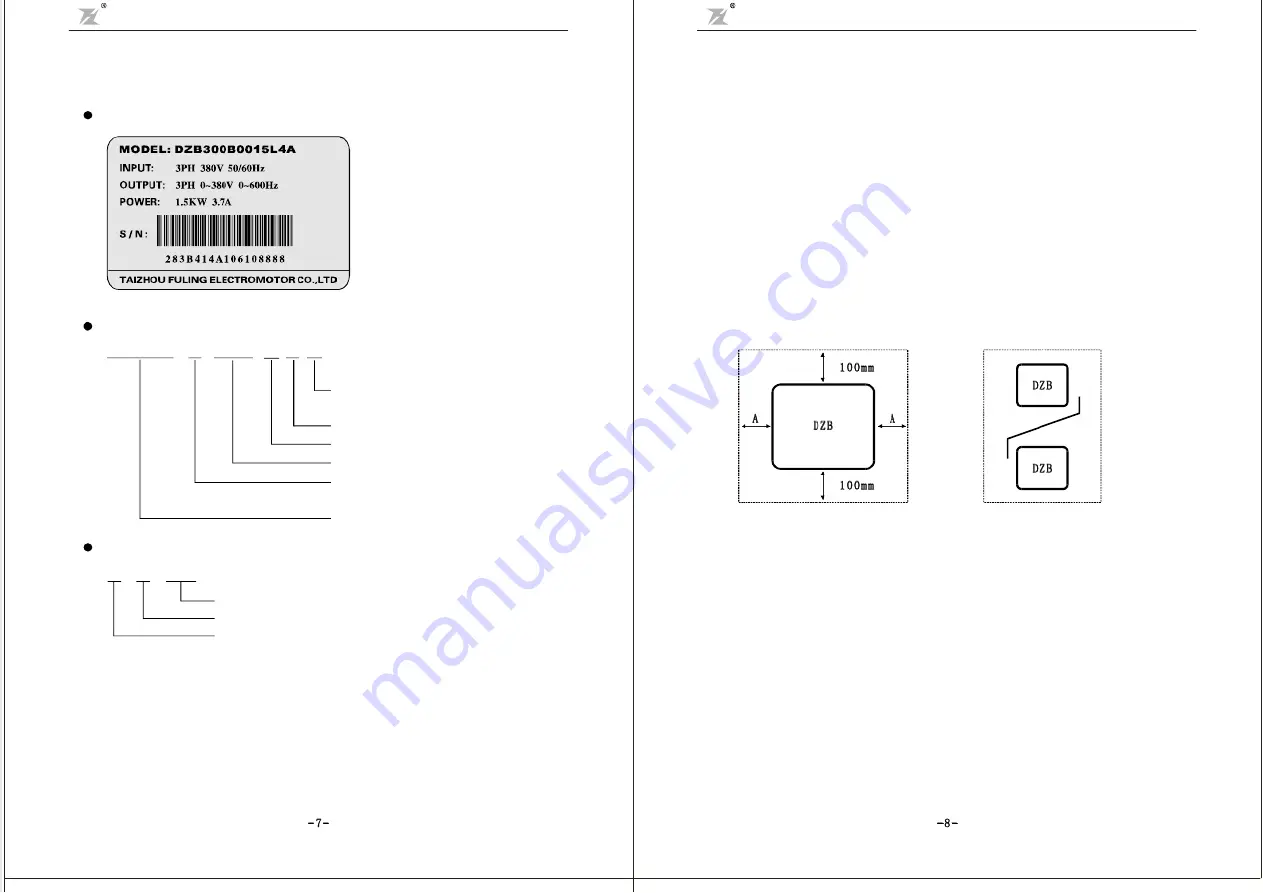

D Z B

up

right

A

≥

1 0 0 m m

≥

1 0 0 m m

A

D Z B

D Z B

Note: No need to consider the dimension

A for inverter of 22kW or below.

A shall be bigger than 50mm for the

inverter of 22kW or above

Note: Install an airflow- guidance

plate for the up and down installation

of inverters.

Fig.3-1 DZB Series Inverter Installation Location

The user shall focus on the heat dissipation issues when installing the inverter, and pay attention to the

following points:

1) Install the inverter vertically so th at the heat may be expelled from the top, but do not install the

inverter upside down. When two Variable Speed Drives are mou nted up and dow n, an air flow

diverting plate should be fixed in between as shown in Fig. 3-1.

2) Installation space is shown in Fig.3-1 so as to ensur e the heat dissipation space, but consider the

heat dissipation of other components when placing the i nverter.

3) The installation bracket must be flame retardant.

4) Install the heat sink outside of the cabinet if the i nverter is installed in the area with metal powder.

And in this case, the space inside the sealing cabi net shall be big enough.

Nameplate

D Z B 3 0 0

B

0 0 1 5

L

4 A

Function level code: A -braking unit inside

B -non braking unit

Input voltage

Freq. Range

Applicable motor capacity

Series

General-Purpose Model

Fan&Pump Model

Seri es name

Serie s

2-220V 4-400V 6-660V

L 0-600.0Hz

0 01 5 1 . 5K W

B:

P:

: DZB300

:

: :

:

为

:

Description ofACMotor Drive Model:

Production number

Production month

Production year

8 8 8 8

1 0

0 6

Description of Serial Number::

2.2 Nameplate Information

- 7 -

- 8 -

I ns ta ll at ion o f s i ng le i nv er te r

U p a nd d ow n i nst al la ti on o f i nv er te rs

Chapter 2 Product Introduction

DZB Series

Chapter 3 Mechanical and Electrical Installation

DZB Series