16

MAINTENANCE (cont.)

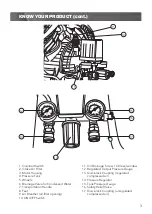

Changing the oil

1.

Switch off the compressor and pull the mains plug out of the

socket.

2.

After releasing any air pressure, you can unscrew the oil drainage

screw (11) from the compressor pump (Fig. 13).

Note:

To prevent the oil from running out in an uncontrolled

manner, hold a funnel under the opening and collect the oil in a

vessel. If the oil does not drain out completely, we recommend

tilting the compressor slightly.

3.

Dispose of the used oil in accordance with local laws.

4.

When the oil has drained out, re-fit the oil drainage screw. Remove the air breather and fill new

oil through the oil filler opening until it comes up to the required level.

5.

Then replace the air breather.

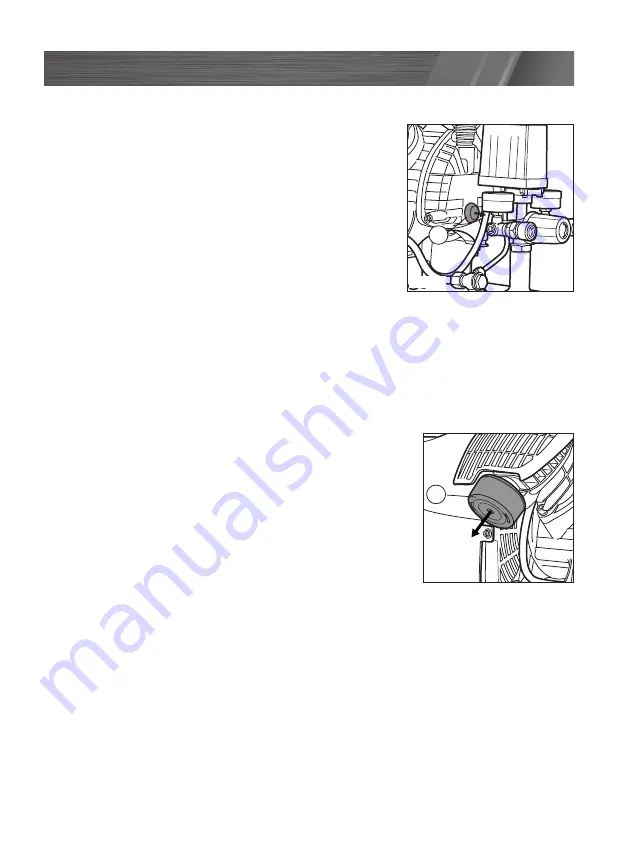

Cleaning the intake air filter (2)

The air intake filter prevents dust and dirt being drawn in. It is essential

to clean this filter after at least every 300 hours in service. A clogged

intake filter will decrease the compressors performance dramatically.

1.

Remove the air intake filter from the compressor and undo the screw

on the top of the air filter as shown in Fig. 14.

2.

You can then remove the filter pad from the two halves of the

plastic housing, tap it to remove the dirt, blast it down with low-

pressure compressed air (approx. 3 bar) and re-insert it.

Refer to page 12, Fig. 4, "Assembly of the air filter" for further information.

Storage

Pull the mains plug out of the socket and ventilate the appliance and all connected pneumatic

tools. Switch off the compressor and make sure that it is secured in such a way that it cannot be

started up again by any unauthorised person.

Store the compressor only in a dry location which is not accessible to unauthorised persons.

Always store upright, never tilted!

Note:

Ozito Industries will not be responsible for any damage or injuries caused by the repair of

the tool by an unauthorised person or by mishandling of the tool.

Fig. 13

Fig. 14

11

2

Summary of Contents for FBACVT-5030

Page 19: ......