8

SET-UP & PREPARATION

WARNING!

Ensure the tool is turned off and disconnected from the power supply before

performing any of the following operations.

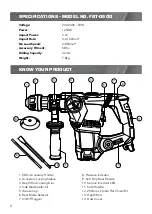

Using the Depth Rod

The Full Boar FBT-0500 comes with a depth rod that allows you

to drill to a pre-determined depth.

1.

Loosen the depth rod securing nut then insert the depth

rod (Fig. 1).

2.

Adjust the depth rod so the drill bit extends beyond the end

of the depth rod to the required drilling depth (Fig. 2).

3.

Tighten the depth rod securing nut to lock the depth rod

into place.

4.

Drill the hole until the end of the depth rod touches the

workpiece.

Fitting SDS+ Accessories

1.

Prior to insertion into the chuck, remove any dust and

debris from the SDS+ accessory, then apply some lubricant

to the end of the accessory.

2.

Pull and hold the locking sleeve back. Insert the SDS+

accessory (Fig. 3).

3.

Rotate the accessory and continue to insert as far as possible

into the chuck. Release the locking sleeve

4.

Check the SDS+ accessory is properly secured in the chuck

by pulling on the accessory. Note: It should have approx.

10-20mm of movement. This is normal. (Fig. 1).

5.

To remove the SDS+ accessory, pull back the locking sleeve and then pull the accessory

out of the chuck.

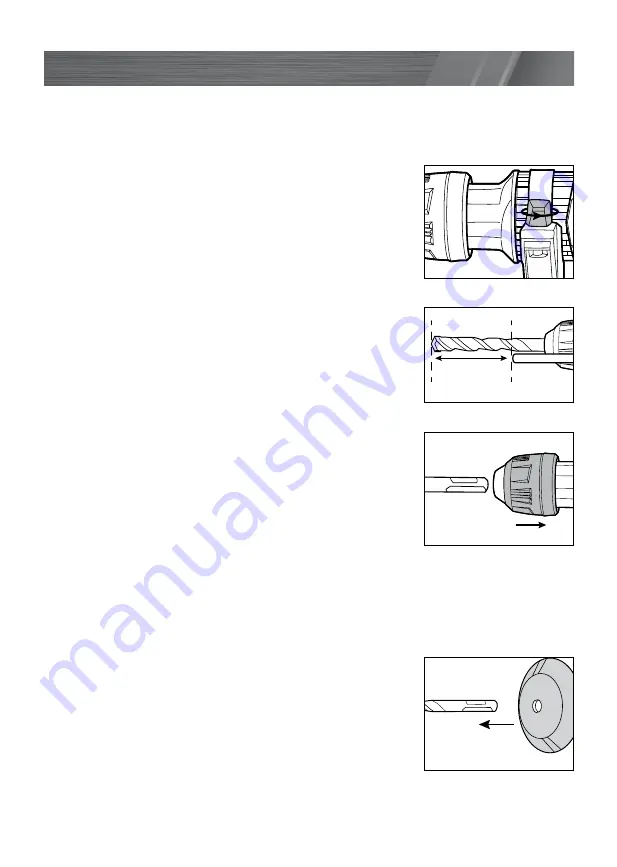

Fitting the Dust Cover

The dust cover catches dust and debris while using the drill in an upright or overhead

positon, helping to avoid dust entering the air vents.

1.

Slide the dust cover over the accessory to be fitted (Fig. 4).

Add lubrication to the end of accessory before inserting into

the SDS+ chuck.

2.

Pull back the accessory locking sleeve and insert the

accessory. Release the locking sleeve.

3.

Press the dust cover into the end of the locking sleeve.

Required Drilling

Depth

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Summary of Contents for FBT-0500

Page 15: ...15...