15

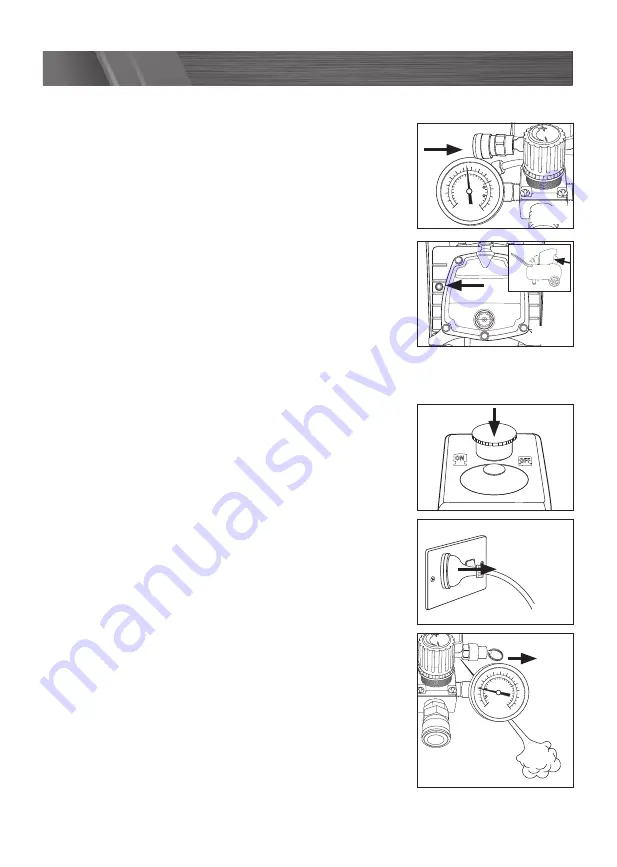

Unregulated quick lock coupling

Air tools can also be attached to the unregulated quick lock

coupling (14) (Fig. 26), but the output pressure level may

fluctuate.

Overload switch

The motor is fitted with an overload switch (17). If the

compressor overloads, the overload switch turns off the

equipment automatically to protect the compressor. If the

overload switch triggers, switch off the compressor using the

ON/OFF switch (9) and wait until the compressor cools down.

Then press the overload switch (17) and restart the compressor

(Fig. 27).

Note.

Long supply cables, extensions, cable reels etc. cause a drop in voltage and can

impede motor start-up.

Turning off

1. After the task has been completed, switch off the

compressor by pressing down the on/off switch (9) (Fig. 28).

2. Wait for the pressurised air to bleed from the release valve

under the pressure switch cover.

3 Switch off the power supply and remove the electrical

plug (Fig. 29).

4. Pull the ring on the safety valve (11) outwards, releasing

the remaining compressed air in the tank. Release the ring

so that the safety valve closes (Fig. 30).

Psi

Bar

10

8

6

4

2

0

50

100

150

200

12

14

Psi

Bar

10

8

6

4

2

0

50

100

150

200

12

14

OPERATION

Psi

Bar

10

8

6

4

2

0

50

100

150

200

12

14

Psi

Bar

10

8

6

4

2

0

50

100

150

200

12

14

Psi

Bar

10

8

6

4

2

0

50

100

150

200

12

14

Psi

Bar

10

8

6

4

2

0

50

100

150

200

12

14

Fig. 26

Fig. 27

Fig. 28

Fig. 29

Fig. 30