12

OPERATION

Electric shock protection

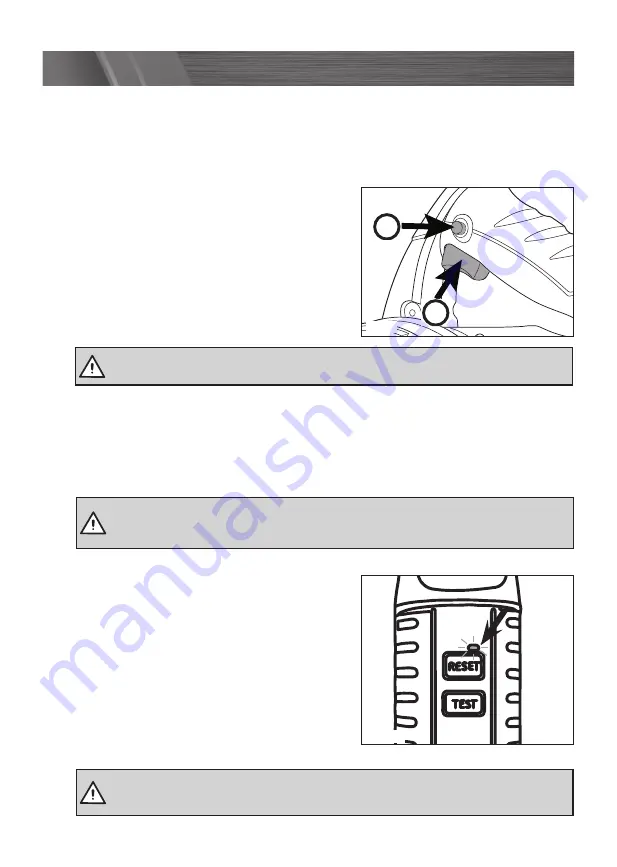

The power cord of the tile cutter includes a Residual Current Device (RCD) (6),

which protects the user against electric shock by interrupting the circuit when a

leakage current of 10 mA or greater is detected.

1.

If the On/Off trigger (2) does not switch on

the tool, press the RESET (8) on the RCD (6).

2.

The LED (7) on the RCD (6) should light up

confirming power is connected to the tool

(fig. 9).

3.

You can test the RCD (6) by pressing the

TEST (9) whilst the tool is running. The

power circuit should be broken and the tile

cutter will stop operation.

WARNING!

Do not use the tool if the RCD (6) does not function properly.

For the RCD to work, the tool must be connected to an earthed power

supply.

Fig. 9

WARNING!

If in the test mode the RCD (6) does not break the circuit, DO

NOT USE THE TOOL. Never use the RCD as a mains switch.

On/off trigger (2)

Always firmly hold the tool by handle (4) during operations. The tile cutter is fitted

with a lock-off button (1) to avoid accidental start up.

1.

First press and hold the lock-off button (1),

then squeeze the On/off trigger (2) to start

the tool. Hold the trigger in this position for

continuous use (fig. 8).

Note:

Once the tool has started, you can

release the lock-off button (1).

2.

To stop the tool, simply release the on/off

trigger (2).

1

2

Fig. 8

WARNING!

Always allow the blade (13) to reach full speed before

performing any cutting operations.