M

M

D

D

2

2

2

2

7

7

8

8

H

H

i

i

g

g

h

h

P

P

e

e

r

r

f

f

o

o

r

r

m

m

a

a

n

n

c

c

e

e

M

M

i

i

c

c

r

r

o

o

s

s

t

t

e

e

p

p

p

p

i

i

n

n

g

g

D

D

r

r

i

i

v

v

e

e

r

r

V

V

1

1

.

.

0

0

8

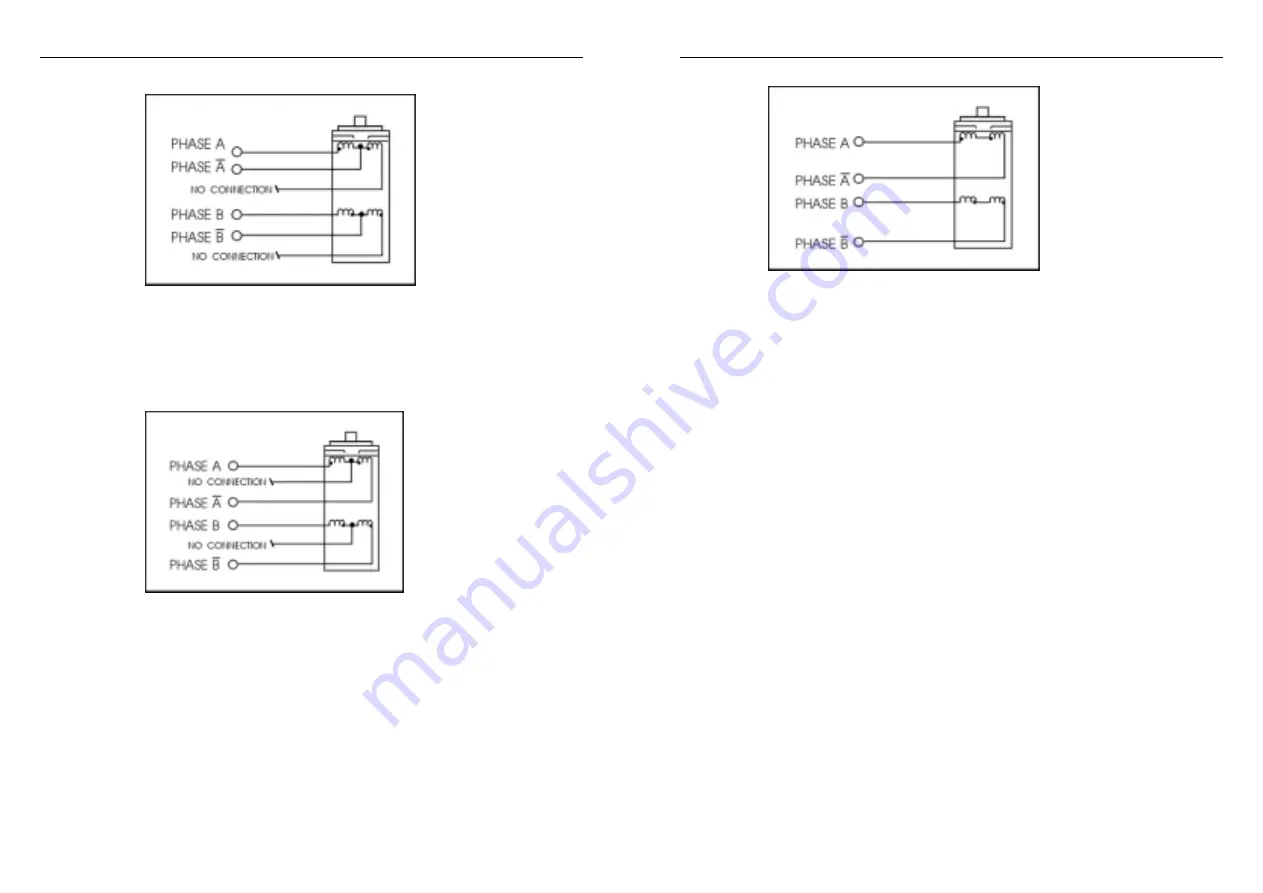

Figure 6: 6 Lead Half Coil (Higher Speed) Motor Connections

Full Coil Confuguration

The full coil configuration on a six lead motor should be used in applications where higher torque

at lower speeds is desired. This configuration is also referred to as full copper. Use the per phase

(or unipolar) current rating as the peak output current.

Figure 7: 6 Lead Full Coil (Higher Torque) Motor

5.3

Connection to 4-Lead Motors

4 lead motors are the least flexible but easiest to wire. Speed and torque will depend on winding

inductance. In setting the driver output current, multiply the specified phase current by 1.4 to

determine the peak output current.

M

M

D

D

2

2

2

2

7

7

8

8

H

H

i

i

g

g

h

h

P

P

e

e

r

r

f

f

o

o

r

r

m

m

a

a

n

n

c

c

e

e

M

M

i

i

c

c

r

r

o

o

s

s

t

t

e

e

p

p

p

p

i

i

n

n

g

g

D

D

r

r

i

i

v

v

e

e

r

r

V

V

1

1

.

.

0

0

9

Figure 8: 4 Lead Motor Connections

6. Power supply Selection, Driver Voltage and Current

Selection

6.1 Power Supply Selection

It is important to choose appropriate power supply to make the driver operate properly and

deliver optimal performance.

Maximum Voltage Input:

The power MOSFETS inside the driver can actually operate 80

-

+220VAC, including

power input fluctuation and back EMF voltage generated by motor coils during motor shaft

deceleration. Higher voltage will damage the driver. Therefore, it is suggested to use power

supplies with theoretical output voltage of no more than +220V, leaving room for power line

fluatuation and Back EMF.

Regulated or Unregulated power supply:

Both regulated and unregulated power supplies can be used to supply DC power to the driver.

However, unregulated power supplies are preferred due to their ability to withstand current

surge. If regulated power supply (such as most switching supplies.) is indeed used, it is

important to have large current output rating to avoid problems like current clamp, for example

using 4A supply for 3A motor-driver operation. On the other hand, if unregulated supply is

used, one may use a power supply of lower current rating than that of motor (typically 50%

~

70% of motor current). The reason is that the driver draws current from the power supply

capacitor of the unregulated supply only during the ON duration of the PWM cycle, but not

during OFF duration. Therefore, the average current withdrawn from power supply is

considerably less than motor current. For example, two 3A motors can be well supplied by one

power supply of 4A rating.