2-1-1

U25MEN

STANDARD MAINTENANCE

Service Schedule of Components

Notes:

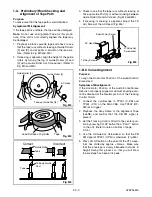

1.Clean all parts for the tape transport (Upper Drum with Video Head / Pinch Roller / Audio Control Head / Full

Erase Head) using 90% lsopropyl Alcohol.

2.After cleaning the parts, do all DECK ADJUSTMENTS.

3.For the reference numbers listed above, refer to Deck Exploded Views.

* B73 ------ Recording Model only

H: Hours : Check

I

: Change

Deck

Periodic Service Schedule

Ref.No.

Part Name

1,000 H

2,000 H

3,000 H

4,000 H

B2

Cylinder Assembly

I

I

B3

Loading Motor Assembly

I

B8

Pulley Assembly

I

I

B27

Tension Lever Sub Assembly

I

I

B31

AC Head Assembly

I

B573,B574

Reel S, Reel T

I

B37

Capstan Motor

I

I

B52

Cap Belt

I

I

*B73

FE Head

I

B133

Idler Assembly

I

I

B410

Pinch Arm (A) Assembly

I

I

B414

M Brake S Assembly

I

I

B416

M Brake T Assembly

I

I

B525

LDG Belt

I

I

Summary of Contents for 25A-664

Page 22: ...1 8 3 1 8 4 1 8 5 HC4S4SCM1 Main 1 5 Schematic Diagram ...

Page 23: ...1 8 6 1 8 7 1 8 8 HC4S4SCM2 Main 2 5 Schematic Diagram ...

Page 24: ...1 8 9 1 8 10 1 8 11 HC4S4SCM3 Main 3 5 Schematic Diagram ...

Page 26: ...Main 5 5 Schematic Diagram 1 8 15 1 8 16 HC4S4SCM5 ...

Page 27: ...VPS Schematic Diagram 1 8 17 1 8 18 HC4S4SCV ...

Page 28: ...1 8 19 1 8 20 HC4S4SCF Function Schematic Diagram ...

Page 29: ...AFV Schematic Diagram 1 8 21 1 8 22 HC4S4SCAFV ...

Page 30: ...Jack Schematic Diagram 1 8 23 1 8 24 HC4S4SCJ ...

Page 31: ...1 8 25 1 8 26 Function CBA Top View Function CBA Bottom View BHC400F01018 B ...

Page 33: ...1 8 29 1 8 30 Jack CBA Top View Jack CBA Bottom View BHC400F01018 E ...

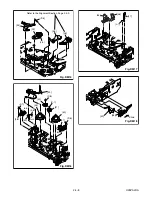

Page 54: ...2 4 6 U25PALDA S 12 19 Cap Belt Fig DM11 Fig DM12 20 C 1 21 ...

Page 60: ...3 1 1 HC4C0FEX A1X EXPLODED VIEWS Front Panel ...

Page 81: ...25A 664 HC4S4ED ...