2-3-4

U25PALMA

6. Press CH DOWN button on the unit until the CTL

waveform has shifted from its original position (not

the position achieved in step 5, but the position of

CTL waveform in step 4) by approximately -2msec.

Make sure that the envelope is simply attenuated

(shrinks in height) once CTL waveform passes its

original position and is further brought in the minus

direction.

7. Set the Tracking Control Circuit to the center posi-

tion by pressing CH UP button and then “ PLAY ”

button.

1-C. Checking/Adjustment of Envelope

Waveform

Purpose:

To achieve a satisfactory picture and precise tracking.

Symptom of Misalignment:

If the envelope output is poor, noise will appear in the

picture. The tracking will then lose precision and the

playback picture will be distorted by any slight varia-

tion of the Tracking Control Circuit.

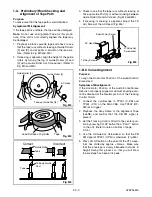

1. Connect the oscilloscope to TP301 (C-PB) on the

Main CBA. Use TP502 (RF-SW) as a trigger.

2. Playback the Gray Scale on the Alignment Tape

(FL6N8). Set the Tracking Control Circuit to the

center position by pressing CH UP button and then

“ PLAY ” button on the unit. Adjust the height of

Guide Rollers [2] and [3] (Fig. M3, Page 2-3-3)

watching the oscilloscope display so that the enve-

lope becomes as flat as possible. To do this adjust-

ment, turn the top of the Guide Roller with the

Guide Roller Adj. Screwdriver.

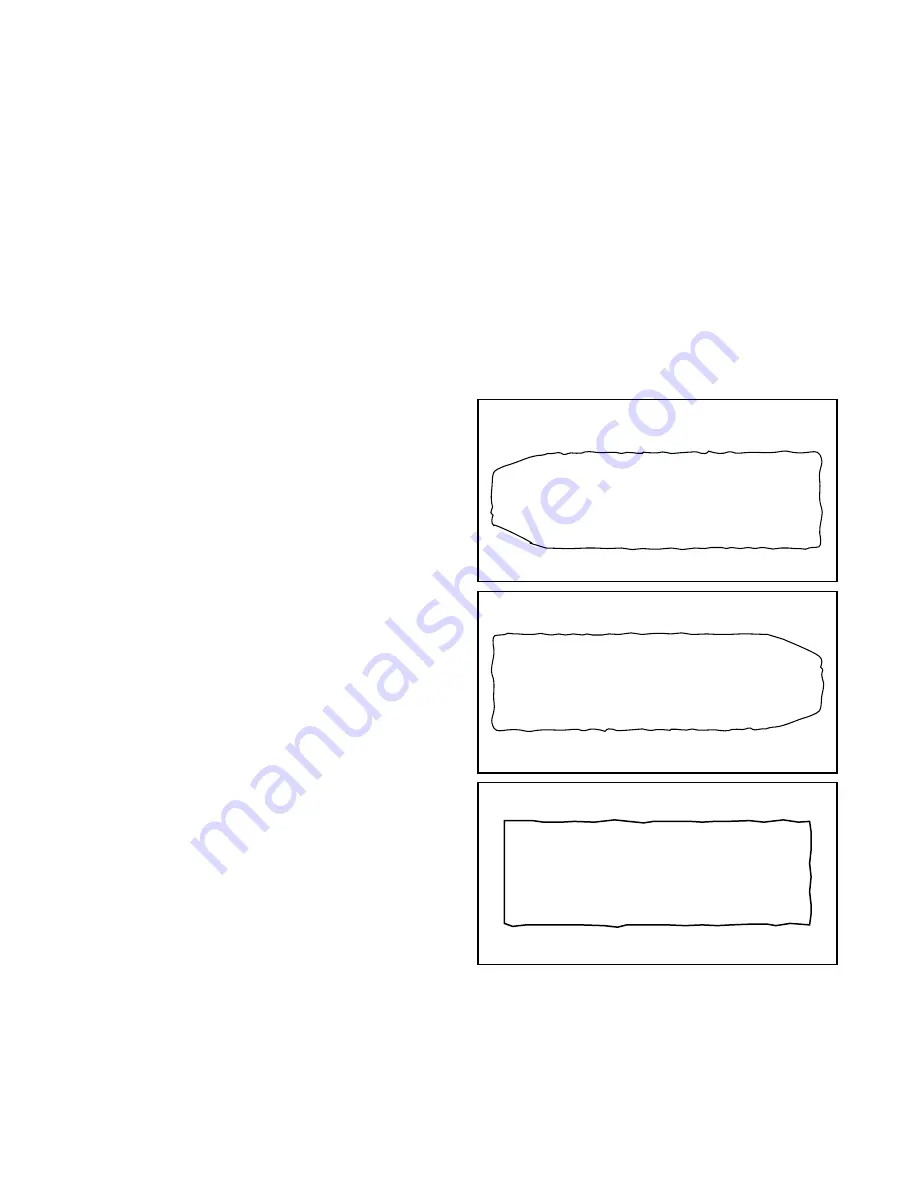

3. If the envelope is as shown in Fig. M7, adjust the

height of Guide Roller [2] (Refer to Fig. M3) so that

the waveform looks like the one shown in Fig. M9.

4. If the envelope is as shown in Fig. M8, adjust the

height of Guide Roller [3] (Refer to Fig. M3) so that

the waveform looks like the one shown in Fig. M9.

5. When Guide Rollers [2] and [3] (Refer to Fig.M3)

are aligned properly, there is no envelope drop

either at the beginning or end of track as shown in

Fig. M9.

Note: Upon completion of the adjustment of Guide

Rollers [2] and [3] (Refer to Fig. M3), check the X

Value by pushing the CH UP or DOWN buttons alter-

nately, to check the symmetry of the envelope. Check

the number of pushes to ensure center position. The

number of pushes CH UP button to achieve 1/2 level

of envelope should match the number of pushes CH

DOWN button from center. If required, redo the “X

Value Alignment.”

1-D. Azimuth Alignment of Audio/Control/

Erase Head

Purpose:

To correct the Azimuth alignment so that the Audio/

Control/Erase Head meets tape tracks properly.

Symptom of Misalignment:

If the position of the Audio/Control/Erase Head is not

properly aligned, the Audio S/N Ratio or Frequency

Response will be poor.

1. Connect the oscilloscope to the audio output jack

on the rear side of the deck.

2. Playback the alignment tape (FL6N8) and confirm

that the audio signal output level is 8kHz.

3. Adjust Azimuth Adj. Screw so that the output level

on the AC Voltmeter or the waveform on the oscil-

loscope is at maximum. (Fig. M6)

Dropping envelope level at the beginning of track.

Fig. M7

Dropping envelope level at the end of track.

Fig. M8

Envelope is adjusted properly. (No envelope drop)

Fig. M9

Summary of Contents for 25A-664

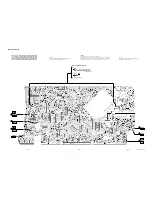

Page 22: ...1 8 3 1 8 4 1 8 5 HC4S4SCM1 Main 1 5 Schematic Diagram ...

Page 23: ...1 8 6 1 8 7 1 8 8 HC4S4SCM2 Main 2 5 Schematic Diagram ...

Page 24: ...1 8 9 1 8 10 1 8 11 HC4S4SCM3 Main 3 5 Schematic Diagram ...

Page 26: ...Main 5 5 Schematic Diagram 1 8 15 1 8 16 HC4S4SCM5 ...

Page 27: ...VPS Schematic Diagram 1 8 17 1 8 18 HC4S4SCV ...

Page 28: ...1 8 19 1 8 20 HC4S4SCF Function Schematic Diagram ...

Page 29: ...AFV Schematic Diagram 1 8 21 1 8 22 HC4S4SCAFV ...

Page 30: ...Jack Schematic Diagram 1 8 23 1 8 24 HC4S4SCJ ...

Page 31: ...1 8 25 1 8 26 Function CBA Top View Function CBA Bottom View BHC400F01018 B ...

Page 33: ...1 8 29 1 8 30 Jack CBA Top View Jack CBA Bottom View BHC400F01018 E ...

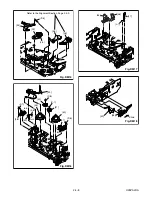

Page 54: ...2 4 6 U25PALDA S 12 19 Cap Belt Fig DM11 Fig DM12 20 C 1 21 ...

Page 60: ...3 1 1 HC4C0FEX A1X EXPLODED VIEWS Front Panel ...

Page 81: ...25A 664 HC4S4ED ...