© www.funkamateur.de

Automatic Antenna Selector

Housing

12

BX-7300 • 180403

Housing

To join the main board and the metal blocks, M3

×

4 cylinder

screws are used while the case housing uses M3

×

4 black

cross head countersunk screws. Next to be assembled are six

metal blocks to the underside and two to the topside of the

board. Attention must be paid that the counter sunk holes on

the blocks are placed facing outwards rather than in, where

later the housing pieces will be screwed in (pictures 20 and

26).

Two blocks are screwed into the ground plate and also the

four rubber feet, for which we use M3

×

10 cross head

screws, M3 nuts for which M3 washers are provided, the lat-

ter used for augmenting the rubberfoot squashing depth and

serve to give a better bearing surface for the screw head

(picture 28).

Then the front panel and the rear panel with the fixed ele-

ments of the main board are screwed together (don’t forget

the three M3

×

6 with nuts to fix the socket board). Finally

the whole assembly is placed on the ground plate and fixed

with the case housing screws. With the case now open, the

lid should be correctly orientated according to the FA-AS

configuration, and screwed in.

The FA-AS requires an earth connection to the rear panel

(picture 25), for which there is an M3

×

8 crosshead screw a

toothed washer and two M3 plain washers provided, further-

more the kit also comes with a soldering eyelet.

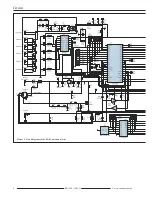

Picture 26. Board underside with the six metal blocks screwed in.

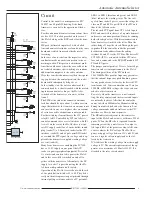

Picture 27. These two blocks on the base plate are used later to

fix the sides.

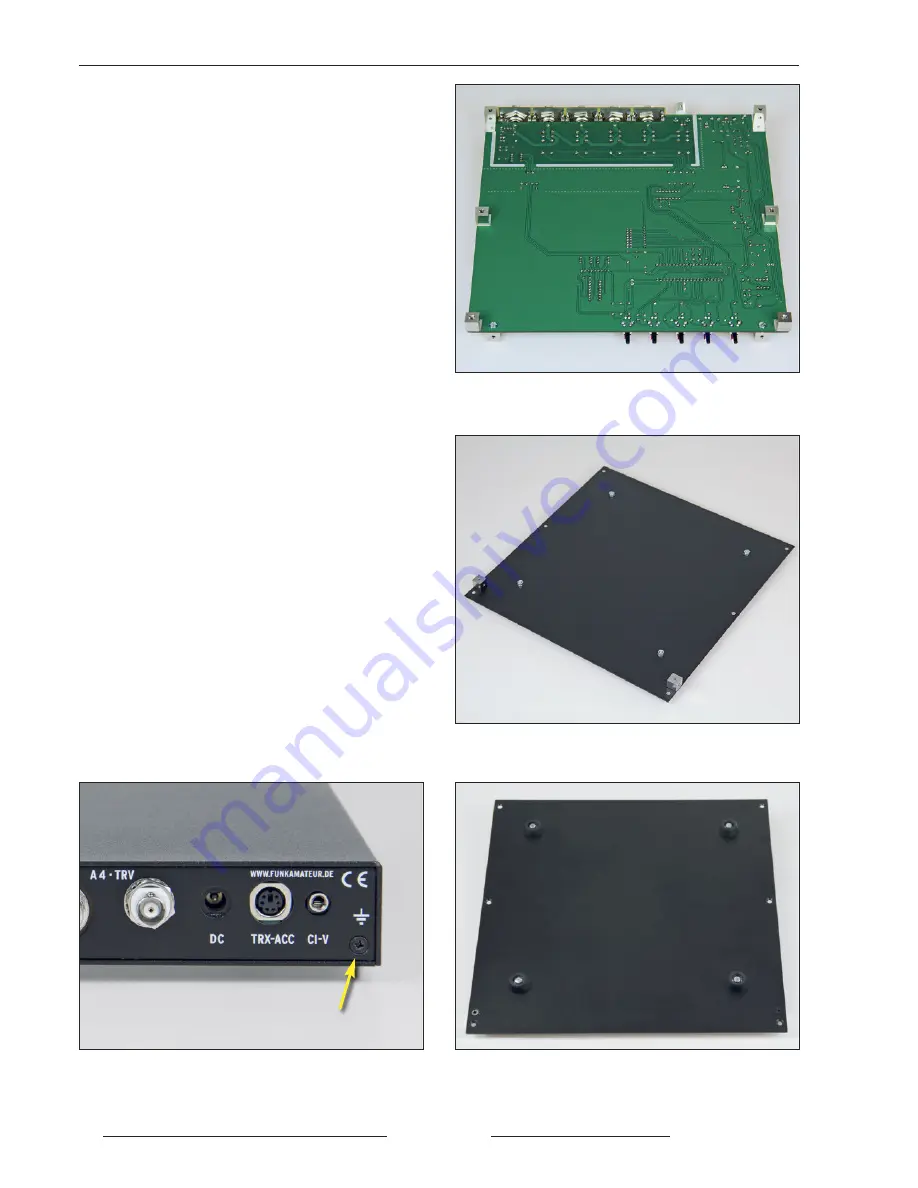

Picture 28. The four rubber feet on the underside of the base

plate are useful later for a steadier stand.

Picture 25. Rear view of the fully built FA- AS; the earth symbol

marks the housing screw which serves as the earthing point.

Summary of Contents for BX-7300

Page 20: ...BX 7300 February 2018...