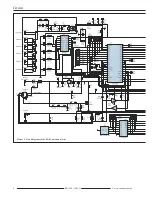

Mounting the IC’s

Now follows the mounting of IC2, IC4, IC5 and IC6. It is of

course, crucial they are mounted in the correct orientation.

The position of the indentation must correspond with the di-

agram on the circuit board. The soldered IC’s can be seen in

pictures 10 to 13.

Mounting the socket board

The approximately 1.5mm gap on the back edge of the main

board is so designed that the socket board can be inserted

later. The milled corners may however need a little further

rounding off with a small file and lastly, the socket plate

must sit flush in the main board gap as shown in picture 14.

With the dimensions of the SO239 sockets adhering to as

high a tolerance as possible it can be that a negligible

amount of filing is required afterwards. The aim is that when

the sockets are mounted and sitting in their corresponding

holes there is as little play as possible and that when the are

being screwed and unscrewed they don’t move or twist and

remain stable. In this case the flat side of the hole (shown in

picture 15) may be carefully and gradually worked so that

the fitted socket has no movement. (In practice only a few

file strokes are needed).

Now the five SO239 sockets are set in a row on the socket

board with the copper side and solder tags facing the same

direction, the nuts located and turned hand tight. Then the

socket board may be screwed to the rear panel using three

black countersunk cabinet screws and M3

×

6 nuts. The

sockets must be aligned as much as possible central to the

rear panel holes and not touching (as shown in picture 16).

With the aid of an appropriate spanner the nuts on the cop-

per coated side of the board are tightened. After which the

rear panel together with the socket board are joined together

with the main board using two metal blocks and two M3

×

4

housing screws and two M3

×

4 cylinder screws. The socket

board is now in the position it will take in the finished hous-

ing and can be mechanically fixed and electrically con-

nected.

There now comes to pass the joining together of the solder

connections of the sockets and main board by the use of a

100W soldering iron and sufficient solder for both sides to

be soldered both from the top of the board and from the un-

derside. This part is shown in a section of the top side of the

main board in picture 17.

When soldering in the corner of the main board it is easier to

have it inclined by 45 deg. Also to bear in mind is that the

insulated leg at any one time is not accidentally bridged to

the adjacent socket section. The legs are quite wide with a

limited tolerance, make sure to check the alignment.

Mounting

Automatic Antenna Selector

BX-7300 • 180403

© www.funkamateur.de

9

Picture 14. The socket board after a little filing, must fit exactly

in the gap of the main board.

Picture 15. If necessary only the flat edges of the through holes

should be carefully worked.

Picture 16. The five SO 239 sockets should be mounted such that

they are centred in the holes on the rear panel.

Picture 17. Shown here a section of soldered main board and

sockets in a row.

Summary of Contents for BX-7300

Page 20: ...BX 7300 February 2018...