CONTENTS

Warnings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

Load Rating

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

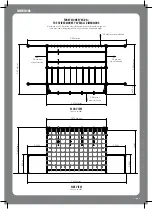

Dimensions .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

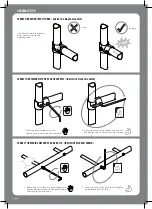

Assembly Tips

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Inventory

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

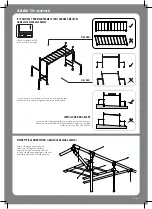

Assembly Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

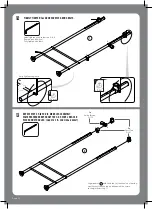

Ladder Bar Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

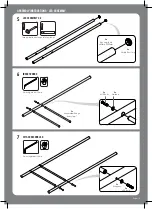

Leg Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

Main Monkey Bar Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

Swing Bar Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 19

Accessories Bar Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21

Cargo Net Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 22

Floating Accessories Bar Assembly.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 25

Twirly Whirly Bar Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

Load Twirly Whirly Bars .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

Sticker Placement Guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 33

Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 34

Page 1

SAFETY NOTICE

1. Any person handling or using the Funky Monkey Bars® products must follow the instructions as described

in this document. The person in charge of assembling and using the equipment must ensure that the

recommendations for use given in this document are seen by all users.

2. Only use the Funky Monkey Bars® after they have been fully assembled and after checking that the

fittings are tightened properly (

refer to page 5 - Correct Tightening Method

).

3. DO NOT install your Funky Monkey Bars® over concrete, asphalt, packed earth, wood decking or any

other hard surface. A fall onto a hard surface can result in serious injury or death.

4. Inspect all grub screws, bolts and nuts at the beginning of each play session to ensure your Funky Monkey

Bars® are tight and secure.

5. Ensure all tubes are fully inserted into fittings until you hear the magic “CLUNK” sound.

6. Ensure your Funky Monkey Bars® are properly secure at ALL times. Pegs are in place and inserted fully into

the ground.

7. DO NOT exceed the maximum load/weight limit as recommended by Funky Monkey Bars®.

8. Children should be supervised by an adult at all times.

9. Installing a gym/crash mat under the fall zone area of your Funky Monkey Bars® would be recommended

for children learning this new skill. This will reduce the chance of injury and build the child’s confidence

while they build strength and master the skill.

10. Ensure you have thoroughly read your assembly and installation instructions and viewed our on-line

installation videos at

https://www.funkymonkeybars.com/blogs/installation-maintenance-videos

11. DO NOT climb, sit or stand on top of the monkey bar (horizontal ladder) section.

12. DO NOT jump from the top of any section of the monkey bar.

13. DO NOT use your Funky Monkey Bars® when wet as the steel will be slippery.

14. DO NOT attach items to your frame that are not designed specifically to be used with Funky Monkey

Bars®, especially lower quality products that have not been approved by Funky Monkey Bars®.

15. Ensure the height of your Funky Monkey Bars® (horizontal ladder) are set at a level that is age appropriate.

16. DO NOT install your Funky Monkey Bars® over or near objects that could interfere with users in an unsafe

way. Maintain a clear area around your Funky Monkey Bars®.

17. DO NOT use your Funky Monkey Bars® while under the influence of drugs and alcohol.

18. Wear clothing free of drawstrings, hooks, loops or anything that could get caught while using your Funky

Monkey Bars® and result in entanglement and/or strangulation.

WARNING

PLEASE CAREFULLY READ ALL INFORMATION CONTAINED IN THIS ASSEMBLY MANUAL BEFORE

YOU INSTALL AND USE YOUR FUNKY MONKEY BARS®.

WARNINGS