Product Specification

Page 6 of 18

1303090MS01

LA-309 Controlled Atmosphere Infrared Furnace

April 15, 2009

5.0 MECHANICAL

SYSTEMS

5.1

OVERALL SIZE

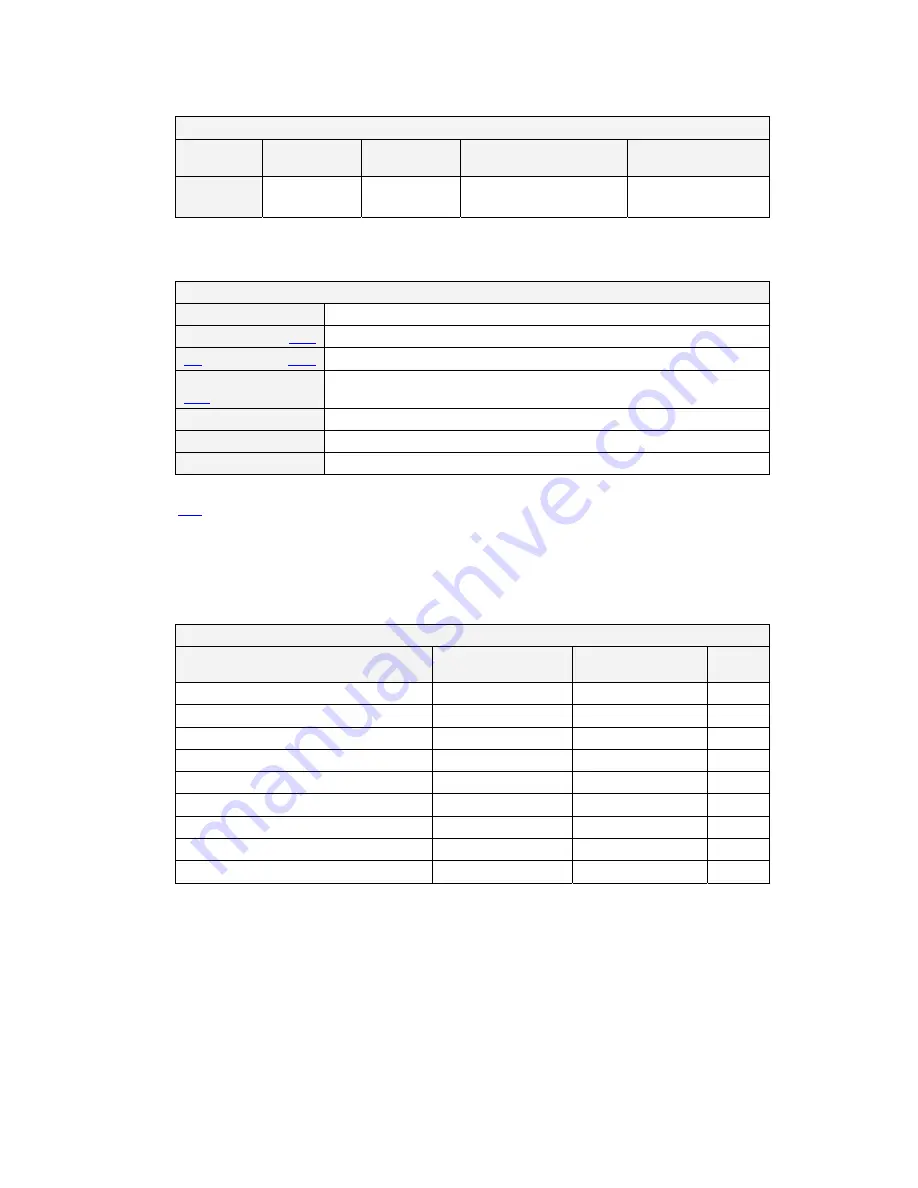

Table 5-1. Furnace Dimensions

Model

Length

(overall)*

Width

(overall)

Height

(overall)

Net Weight (approx.)

LA-309

128 in

(3.13 m)

37.9 in

(0.963 m)

67 ± 1.5 in adjustable

(1.702 ± .038 m)

1600 LB

(730 kg)

*length includes optional IR-E & IR-X interface rollers at entrance and exit respectively.

5.2

TRANSPORT SYSTEM

Table 5-2. Transport System

Belt width

9 in (23 cm)

Std belt material,

316 Stainless Steel, balanced spiral weave.

Nichrome V, 80%Ni / 20%Cr alloy (<1% Fe), balanced spiral weave.

Product clearance,

0.4-2 in (1-5.1 cm) above belt level. The entrance and exit throat, baffle

plates, and zone dividers shall be set to provide this clearance.

Belt support

Quartz rods in process chamber, UHMW-PE on belt return.

Belt speed range

2-20 ipm (5.1-51 cm/min)

Conveyor height

36 in ± 1.5 in (91.4 ± 3.8 cm); user adjustable.

5.3

MECHANICAL INDEPENDENT ZONE GAS CONTROL

5.3.1

Flowmeters.

A system of variable rate flowmeters and piping shall enable operators to

control introduction of Process Gas into the furnace diffused through porous ceramic refractory

chamber walls. Variable rate flowmeters shall also control flow to other equipment shown in

Table 5-3.

Table 5-3. Furnace Atmosphere Gas Flow Control

Location

Flow Meter Range

Scale Graduation

Flow Meter Range

Scale Graduation

Gas

Entrance Exhaust Eductor

0-20 L/min

0-50 scfh

CDA

Entrance Baffle

0-50 L/min

0-100 scfh

N

2

Heating Chamber, Zone 1

0-50 L/min

0-100 scfh

N

2

Heating Chamber, Zones 2 & 3

0-50 L/min

0-100 scfh

N

2

Exit Baffle - Insulated Transition Tunnel

0-50 L/min

0-100 scfh

N

2

Transition Tunnel Exhaust Eductor

0-20 L/min

0-50 scfh

CDA

CACT Cooling Air Rakes

0-90 L/min

0-200 scfh

N

2

Lamp Plenum Seals

0-50 L/min

0-100 scfh

N

2

Total – LA-309

380 L/min

800 scfh

5.3.2

Security.

The variable rate flowmeters shall be enclosed behind a clear panel. Customer can

restrict access to the flowmeters by one of three methods: Keyed lock, mechanical latch or

fastened by screws (lock and latch shall both be provided).

5.3.3

Atmosphere shall be controlled by manual adjustment of the flowmeters.

Summary of Contents for LA-309

Page 5: ...10 004 676 110000 v WARRANTY Warranty goes here ...

Page 6: ...vi LA 309 Owner s Manual ...

Page 12: ...Contents xii LA 309 Owner s Manual ...

Page 20: ...Section 1 1 8 LA 309 Owner s Manual ...

Page 68: ...Section 3 3 28 LA 309 Owner s Manual ...

Page 70: ...Section 4 4 2 LA 309 Owner s Manual ...

Page 72: ...Section 4 4 4 LA 309 Owner s Manual ...

Page 98: ...Section 5 5 2 LA 309 Owner s Manual ...

Page 100: ...Section 5 5 4 LA 309 Owner s Manual ...

Page 106: ...Section 5 5 10 LA 309 Owner s Manual ...

Page 108: ...Section 5 5 12 LA 309 Owner s Manual ...

Page 110: ...Section 5 5 14 LA 309 Owner s Manual ...

Page 112: ...Section 6 6 2 LA 309 Owner s Manual ...

Page 114: ......

Page 115: ......

Page 126: ...Section 7 1 Fiberfrax Cements MSDS 042006 Owner s Manual ...

Page 139: ...MSDS 2 Fiberfrax Duraboard MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 140: ...Section 7 2 Fiberfrax Duraboard MSDS 042006 Owner s Manual ...

Page 153: ...MSDS 3 Fiberfrax Fibers MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 154: ...Section 7 3 Fiberfrax Fibers MSDS 042006 Owner s Manual ...

Page 167: ...MSDS 4 Fiberfrax Papers MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 168: ...Section 7 4 Fiberfrax Papers MSDS 042006 Owner s Manual ...

Page 181: ...MSDS 5 Magnaform MSDS 050406 MATERIAL SAFETY DATA SHEETS ...

Page 182: ...Section 7 5 Magnaform MSDS 050406 Owner s Manual ...

Page 183: ......

Page 184: ......

Page 185: ...Section 7 6 RTU Silicone Red Hi Temp 042006 Owner s Manual ...

Page 186: ...MSDS 6 RTU Silicone Red Hi Temp 042006 MATERIAL SAFETY DATA SHEETS ...

Page 189: ...Section 7 7 Kaowool Insulation MSDS 050406 Owner s Manual ...

Page 190: ...MSDS 7 Kaowool Insulation MSDS 050406 MATERIAL SAFETY DATA SHEETS ...

Page 201: ...Material Safety Data Sheets 7 15 Notes ...

Page 202: ...Section 7 7 16 Owner s Manual ...

Page 204: ...Section 8 Owner s Manual ...

Page 206: ...Section 8 Owner s Manual ...

Page 212: ...iv Operation and Troubleshooting ...

Page 214: ...vi Operation and Troubleshooting ...

Page 224: ...Page 10 Operation and Troubleshooting ...

Page 231: ...9 1 Section 9 APPENDIX B 9 1 EC913 CALIBRATION REPORT 9 2 SERIES EC900 OXYGEN ANALYZERS ...

Page 232: ...Section 8 Owner s Manual ...

Page 233: ......

Page 234: ...Section 8 Owner s Manual ...

Page 279: ...Section 8 Owner s Manual ...

Page 281: ...MSDS MATERIAL SAFETY DATA SHEETS ...

Page 282: ...16 Notes ...