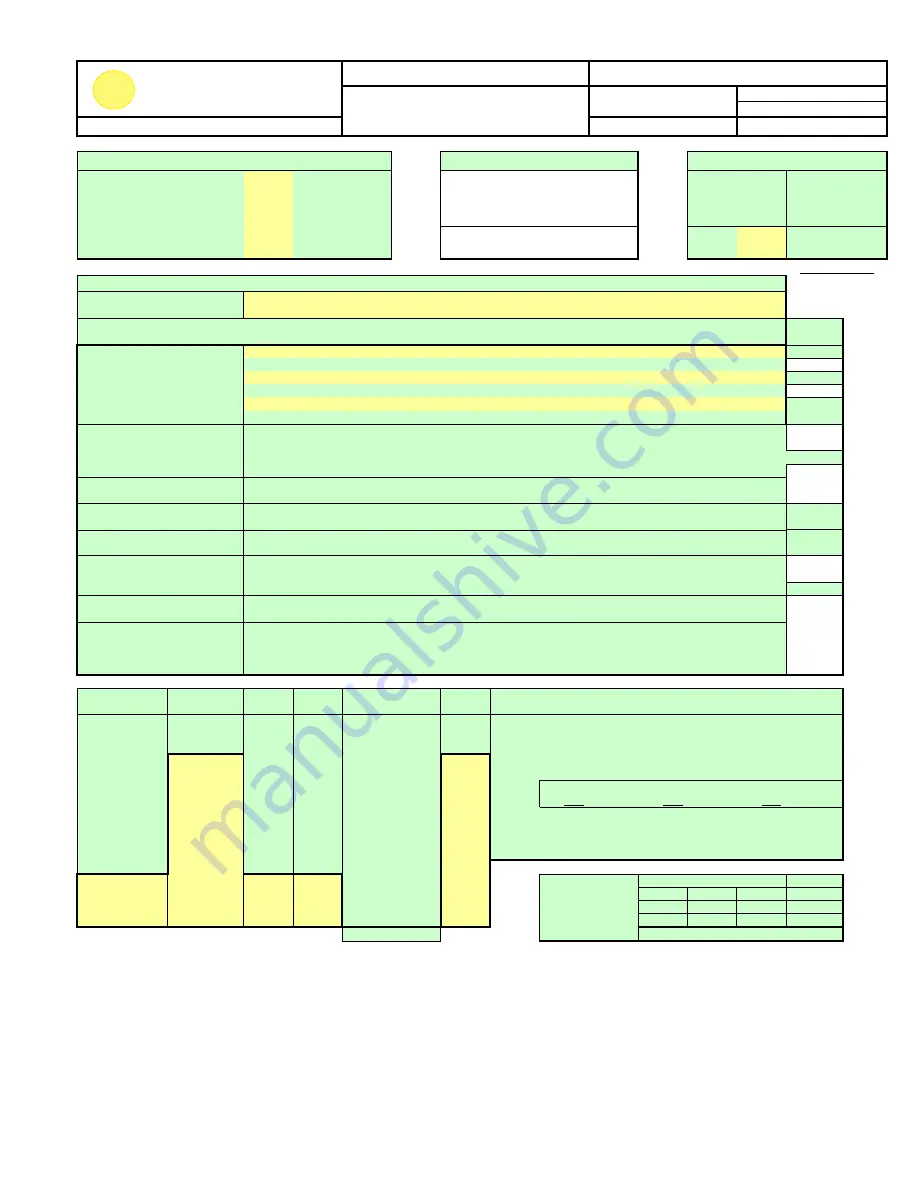

DOC NBR:

802-101500

R 1

MODEL:

APVL

SLB

9/2/09

SERIAL NBR:

PRNT

Customer:

OMS RATTO

DATE:

of

1

INPUT TABLE

Entry OK?

VALID

380

Vac

TRUE

Max Power:

23.6 kW

Lamps: 28

SCRs: 8

N

TRUE

50

Hz

TRUE

9

inches

TRUE

Typical Power:

8.6 kW

Nbr Lamps

AOV-25: 4

35

%

TRUE

Typical Current:

13.1 A

in 10" zone:

AITM: 2

SCR PHASE

Zone Entry OK?

VALID

VALID

VALID

Phase 1: 5.9

1

2

3

Phase 2: 8.9

1

2

3

Phase 3: 5.9

Zone

Zone

Zone

Zone

Zone

Zone

Zone

Zone

Zone

Zone

Zone

SCR POWER

1

2

3

4

5

6

7

8

9

10

11

Totals

7.5

15

7.5

30 in.

TRUE

TRUE

TRUE

F

F

F

3

TRUE

TRUE

TRUE

2

2

2

Plenum:

TRUE

TRUE

TRUE

120

Rated Lamp Voltage

216

216

216

Max. Lamp Wired Voltage

190

190

190

50% Power SCR Cal Span Setting

268

268

268

<-- Vrms

Max. Lamp Wired Power (W)

739

739

739

No. Strings per SCR

2

3

2

Max. Current per String (A)

3.9

3.9

3.9

No. Lamps in Zone

8

12

8

28

No. Lamp SCRs in Zone

2

2

2

6

No. Strings in Furnace Zones

4

6

4

14

4

Top Lamp Power (kW)

3.0

4.4

3.0

Bottom Lamp Power (kW)

3.0

4.4

3.0

Total Power/Zone (kW)

5.9

8.9

5.9

20.7

Current Required Top SCR (A)

7.8

11.7

7.8

Current Required Bottom SCR (A)

7.8

11.7

7.8

Color Temp (K) (nominal: 2500K)

2384

2384

2384

Peak Wavelength (µm)

1.22

1.22

1.22

Estimated Lamp Life (hrs)

Long

Long

Long

Lumen Output vs. Rated (%)

66

66

66

Number of

Voltage

Current

Phase

Item?

(Vac)

(Amps)

Max

Typical Assigned

Lamps

28

380

as above

20.7

7.2 as above

10" Cabinet or CACT Fans, 117 Vac, 0.30/0.29 A for 50/60 Hz

PC, Monitor

1

117

1.3

0.2

0.2

1

4" Box (Muffin) Fans, product cooling, 117 Vac, 0.16 A

Belt, Opto22, EM

1

117

2.1

0.2

0.2

1

Cross-flow Fans, product cooling, 230 Vac, 1.27 A max

UC (Pump & Gen)

117

10.0

Lower Cabinet Blowers (Impellers), 230 Vac, 0.72 A max

UC (Tank Heater)

117

8.4

UCD (Blower)

117

2.0

No more than 8 SCRs/phase per TRx xfmr 24 Vac secondary

UCD (Heater)

380

12.7

TR1: 4

TR2: 2

TR3: 2

Edg Htr 1

Length

30

380

6.2

2.3

0.8

1

OK

Max Curr/EH1 SCR:

3 A

Edg Htr 2

Length

Max Curr/EH2 SCR:

Edg Htr 3

Length

Max Curr/EH3 SCR:

Cabinet Fans 10"

2

117

0.3

0.1

0.1

1

OK

Cabinet/CACT Fans:

1.2 A

CACT Fans 10"

2

117

0.3

0.1

0.1

1

OK

Cooling Fans 4"

117

0.16

TOTAL

Cross-flow Fans

230

1.27

1

2

3

ALL

Cabinet Blowers

230

0.72

5.9

8.9

5.9

20.7

EH/OTHER

1.4

0.0

0.0

1.4

23.6

8.6

TOTAL

7.3

8.9

5.9

22.0

Furnace Totals:

6

No. Lamps in Series/String (1-5)

Lamps/String OK?

No. Furnace Element Monitors

LAMP PWR, kW

3

Lamp Balance (kW)

Top Lamp Phase (1/2/3):

Bottom Lamp Phase (1/2/3):

A

Max Current:

EMs: 4

TCs:

Length (7.5/10/15/20/30) in inches

PHASE BALANCING

PHASE

Furnace Total

Power (kW)

Other Items

Limit Lamps to Max Rating?

(Y/N)

Line Frequency

(50/60)

Lamp Length

(6, 9, 15, 24, 36)

Typical Operating %

Wed, Oct 06, 2010

SHT

1

Enter Power Line Tap Voltage:

(208, 220, 240, 277, 380, 415, 440, 480)

SUMMARY OF RESULTS

HARDWARE

(F)urn., Furn. (1) SCR-Zn, (D)ryer

Zone Type OK?

10-004

IR FURNACE SYSTEM

POWER & CURRENT

DATA SHEET

1303091001

LA-309

05/18/10

35.8

Length Entry OK?

FurnacePros

DIVISION OF LOCHABER CORNWALL, INC.

Furnace Power ©LOCHABER CORNWALL, INC.

Summary of Contents for LA-309

Page 5: ...10 004 676 110000 v WARRANTY Warranty goes here ...

Page 6: ...vi LA 309 Owner s Manual ...

Page 12: ...Contents xii LA 309 Owner s Manual ...

Page 20: ...Section 1 1 8 LA 309 Owner s Manual ...

Page 68: ...Section 3 3 28 LA 309 Owner s Manual ...

Page 70: ...Section 4 4 2 LA 309 Owner s Manual ...

Page 72: ...Section 4 4 4 LA 309 Owner s Manual ...

Page 98: ...Section 5 5 2 LA 309 Owner s Manual ...

Page 100: ...Section 5 5 4 LA 309 Owner s Manual ...

Page 106: ...Section 5 5 10 LA 309 Owner s Manual ...

Page 108: ...Section 5 5 12 LA 309 Owner s Manual ...

Page 110: ...Section 5 5 14 LA 309 Owner s Manual ...

Page 112: ...Section 6 6 2 LA 309 Owner s Manual ...

Page 114: ......

Page 115: ......

Page 126: ...Section 7 1 Fiberfrax Cements MSDS 042006 Owner s Manual ...

Page 139: ...MSDS 2 Fiberfrax Duraboard MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 140: ...Section 7 2 Fiberfrax Duraboard MSDS 042006 Owner s Manual ...

Page 153: ...MSDS 3 Fiberfrax Fibers MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 154: ...Section 7 3 Fiberfrax Fibers MSDS 042006 Owner s Manual ...

Page 167: ...MSDS 4 Fiberfrax Papers MSDS 042006 MATERIAL SAFETY DATA SHEETS ...

Page 168: ...Section 7 4 Fiberfrax Papers MSDS 042006 Owner s Manual ...

Page 181: ...MSDS 5 Magnaform MSDS 050406 MATERIAL SAFETY DATA SHEETS ...

Page 182: ...Section 7 5 Magnaform MSDS 050406 Owner s Manual ...

Page 183: ......

Page 184: ......

Page 185: ...Section 7 6 RTU Silicone Red Hi Temp 042006 Owner s Manual ...

Page 186: ...MSDS 6 RTU Silicone Red Hi Temp 042006 MATERIAL SAFETY DATA SHEETS ...

Page 189: ...Section 7 7 Kaowool Insulation MSDS 050406 Owner s Manual ...

Page 190: ...MSDS 7 Kaowool Insulation MSDS 050406 MATERIAL SAFETY DATA SHEETS ...

Page 201: ...Material Safety Data Sheets 7 15 Notes ...

Page 202: ...Section 7 7 16 Owner s Manual ...

Page 204: ...Section 8 Owner s Manual ...

Page 206: ...Section 8 Owner s Manual ...

Page 212: ...iv Operation and Troubleshooting ...

Page 214: ...vi Operation and Troubleshooting ...

Page 224: ...Page 10 Operation and Troubleshooting ...

Page 231: ...9 1 Section 9 APPENDIX B 9 1 EC913 CALIBRATION REPORT 9 2 SERIES EC900 OXYGEN ANALYZERS ...

Page 232: ...Section 8 Owner s Manual ...

Page 233: ......

Page 234: ...Section 8 Owner s Manual ...

Page 279: ...Section 8 Owner s Manual ...

Page 281: ...MSDS MATERIAL SAFETY DATA SHEETS ...

Page 282: ...16 Notes ...