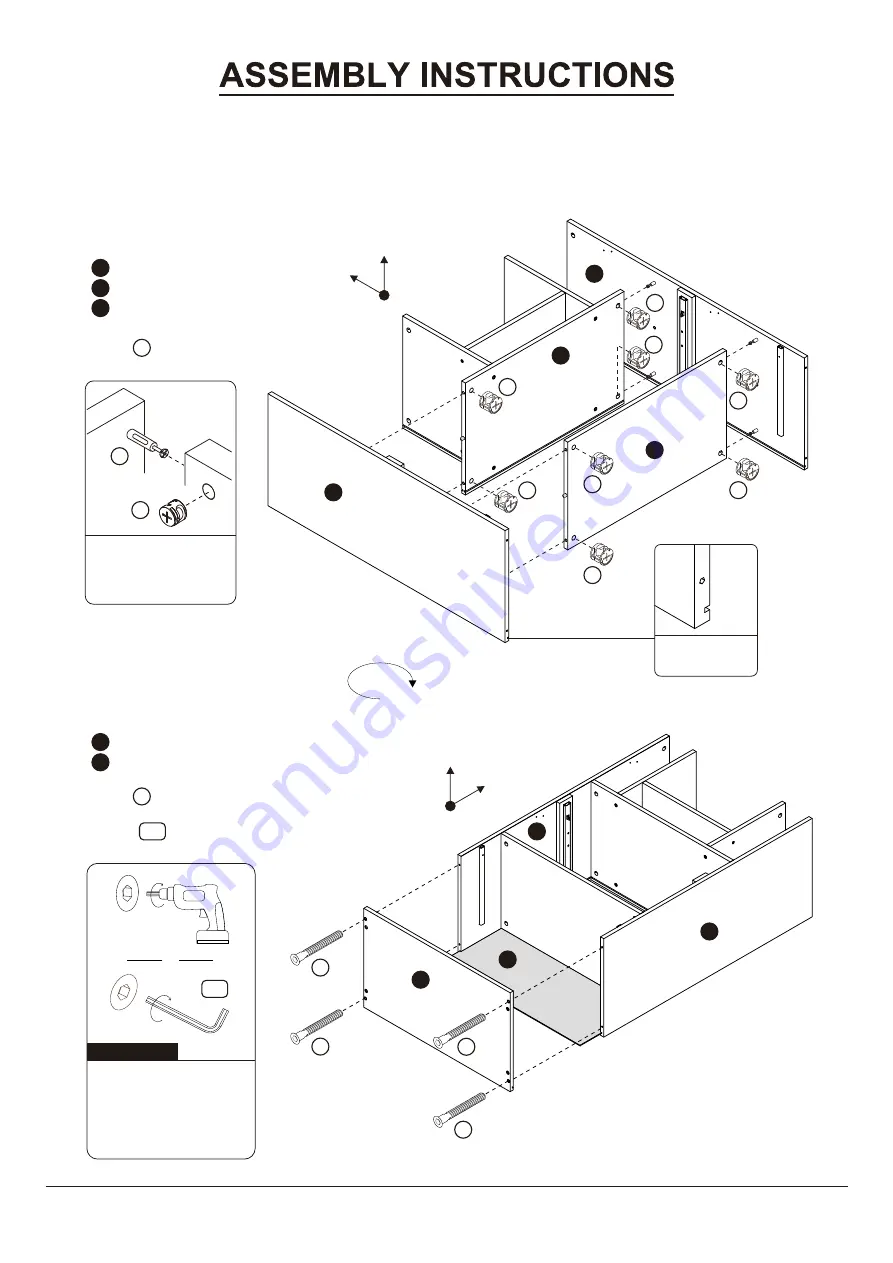

7

8

Part

x1PC

H

Accessory

x1PC

A2

Part

x1PC

Y

Hardware x4PCS

5

Hardware x8PCS

2

Part

x1PC

J

or

A2

Recommend using a power

tool to only tighten

hardware (#5) faster.

Accessory (#A2) could also

work for hardware (#5) if a

power tool is not present.

RECOMMEND

Please refer to page 5 for

detailed instructions on

how to fasten cam locks

(#

2) to cam bolts (#1).

1

2

Part

x1PC

G

Part

x1PC

I

2

2

2

2

2

2

2

2

G

J

F

I

Front

Top

Front

Top

Rotate

90°

5

5

5

5

H

Y

J

I

Thin line gap of

panel (#I) here.