i

SAFETY INSTRUCTIONS

WARNING

Turn off the power at the switchboard

before beginning the installation.

Fire or electrical shock can result if the

power is left on.

Do not install the equipment where it

may get wet from rain or water splash.

Water in the equipment can result in fire,

electrical shock or equipment damage.

Be sure no water leaks in at the trans-

ducer mounting location.

Water leakage can sink the vessel. Also,

confirm that the transducer will not loosen

by ship's vibration. The installer of the

equipment is solely responsible for the

proper installation of the equipment.

FURUNO will assume no responsibility for

any damage associated with improper

installation.

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or equipment damage. The

voltage rating of the equipment appears

on the label above the power connector.

ELECTRICAL SHOCK HAZARD

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

Only qualified personnel

should work inside the

equipment.

WARNING

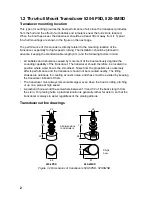

Install the transducer according

to the installation instructions.

Failure to install the transducer correctly

may result in water leakage and damage to

the ship's hull.