2. WIRING

2-5

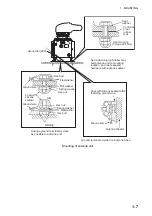

10. Connect the coaxial cable to TB802 on the TB board and clamp the shield with the

cable clamp on the TB board.

11. Remount the TB board assembly.

12. Connect the shield wire to the grounding point as shown in the figure above.

13. Seal the cable gland with putty.

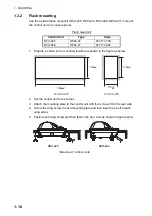

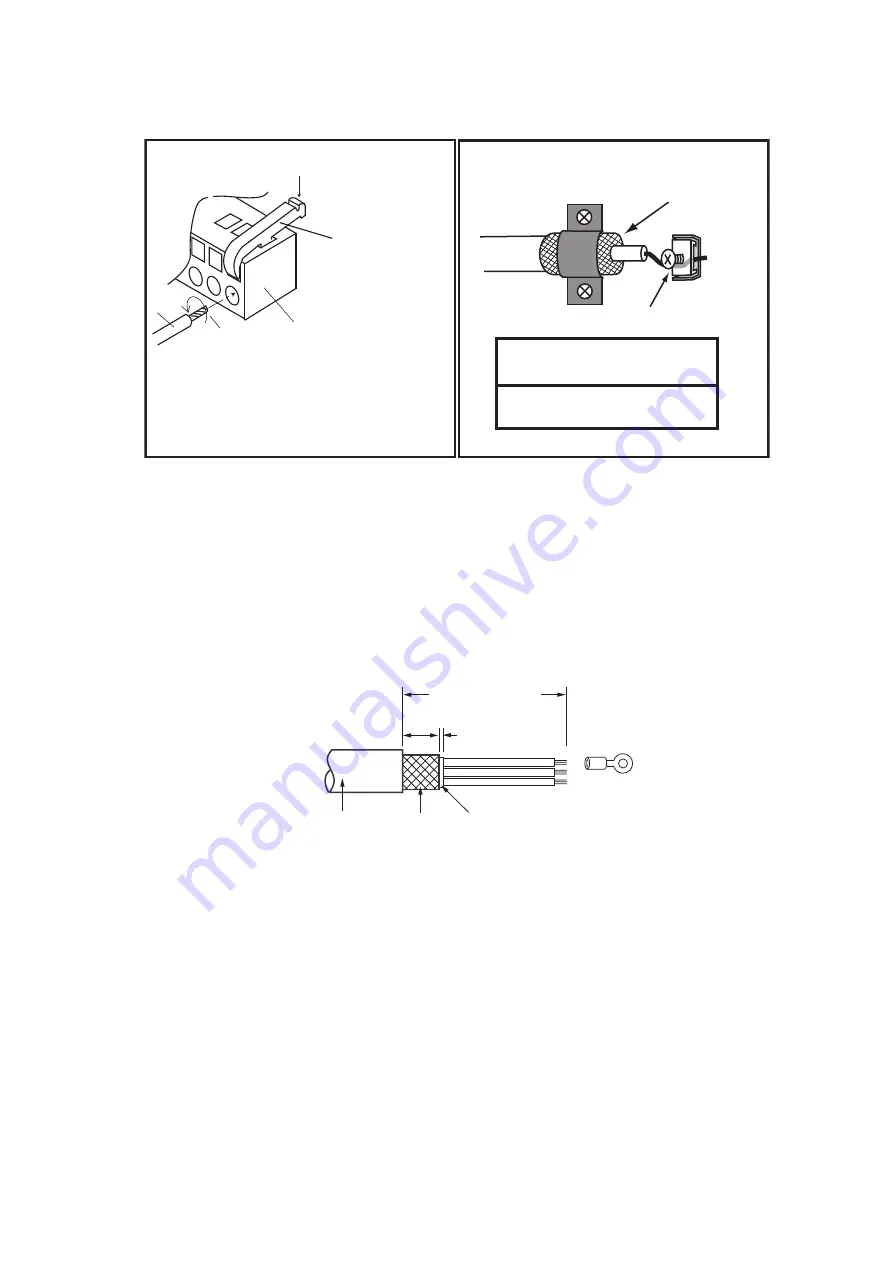

Fabricating power cable TPYCY-2.5

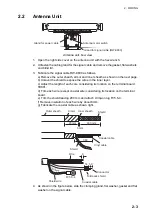

1. Open the left side cover on the antenna unit with the hex wrench.

2. Fabricate the cable as shown below. Use TPYCY-2.5 (Japan Industry Standard)

cable or equivalent.

Fabricating the power cable TPYCY-2.5

3. At the power cable gland on the antenna unit, unfasten the clamping gland and

remove gasket, flat washers and blind lid.

Wiring for Coaxial cable

CAUTION

Clamp shied with bracket.

Tighten conductor with screw.

Procedures

1. Twist the conductor.

2. Press the terminal opener downward.

3. Insert the wire to hole.

4. Remove the terminal opener.

5. Pull the wire to confirm that it is ecure.

Terminal opener

Wiring for WAGO connector

WAGO connector

Wire

Twist

Press downward.

Do not use crimp-on lug to prevent

contact resistance from increasing.

25 mm

5 mm

FV2-4

Sheath

Armor

Anti-corrosive

Vinyl sheath

Approx. 170 mm

Summary of Contents for FCR-2139S-BB

Page 74: ...2 WIRING 2 48 This page is intentionally left blank ...

Page 136: ...D 1 14 Feb 2011 Y NISHIYAMA ...

Page 137: ...D 2 Y Hatai ...

Page 138: ...May17 07 R Esumi D 3 ...

Page 139: ...13 Feb 2014 H MAKI D 4 ...

Page 140: ...D 5 24 May 2012 Y NISHIYAMA ...

Page 141: ...D 6 24 May 2012 Y NISHIYAMA ...

Page 142: ...D 7 24 May 2012 Y NISHIYAMA ...

Page 143: ...D 8 ...

Page 144: ...D 9 ...

Page 145: ...D 10 ...

Page 148: ...13 Jan 2012 Y NISHIYAMA 西山義浩 D 13 ...

Page 149: ...13 Jan 2012 Y NISHIYAMA D 14 ...

Page 150: ...D 15 ...