i

SAFETY INSTRUCTIONS

2

2

2

2

*1

*2

The operator and installer must read the applicable safety instructions before attempting to

install or operate the equipment.

DANGER

WARNING

Indicates a potentially hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

can result in minor or moderate injury.

Warning, Caution

Prohibitive Action

Mandatory Action

DANGER

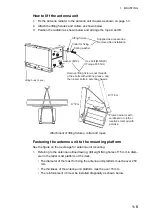

Wear a safety belt and hard hat when working on the antenna unit.

Serious injury or death can result if someone falls from the radar antenna

mast.

WARNING

Radio Frequency Radiation Hazard

The radar antenna emits electromagnetic radio frequency (RF) energy which can be

harmful, particularly to your eyes. Never look directly into the antenna aperture from a close

distance while the radar ius in operation or eexpose yourself to the transmitting antenna at a

close distance. Distances at which RF radiation level of 100, 50 and 10 W/m are given in the

table below.

Note:

if the antenna unit is installed at a close distance in front of the wheel house, your

administration may require halt of transmission within a certain sector of antenna

revolution.

This is possible. Ask your FURUNO representive or dealer to provide this feature.

Mode

Magnetron

Antenna

100W/m

50W/m

10W/m

FCR-2139S-BB /

FCR-2839S

RTR-080

(S-30 kw)

MG5223F

SN36AF

0.1 m

0.7 m

2.0 m

*1

*2

SN36AF: 12 ft

FCR-2139S-BB: available in blackbox configuration.

Transceiver

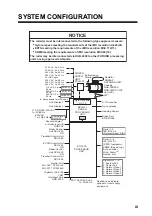

Summary of Contents for FCR-2139S-BB

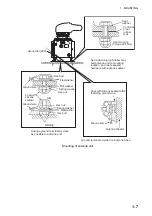

Page 74: ...2 WIRING 2 48 This page is intentionally left blank ...

Page 136: ...D 1 14 Feb 2011 Y NISHIYAMA ...

Page 137: ...D 2 Y Hatai ...

Page 138: ...May17 07 R Esumi D 3 ...

Page 139: ...13 Feb 2014 H MAKI D 4 ...

Page 140: ...D 5 24 May 2012 Y NISHIYAMA ...

Page 141: ...D 6 24 May 2012 Y NISHIYAMA ...

Page 142: ...D 7 24 May 2012 Y NISHIYAMA ...

Page 143: ...D 8 ...

Page 144: ...D 9 ...

Page 145: ...D 10 ...

Page 148: ...13 Jan 2012 Y NISHIYAMA 西山義浩 D 13 ...

Page 149: ...13 Jan 2012 Y NISHIYAMA D 14 ...

Page 150: ...D 15 ...