APPENDIX 2 INSTALLATION OF TEMPERATURE SENSORS

AP-4

Maintenance & Replacement

Aquatic growth can accumulate rapidly on the sensor’s surface

reducing its performance within weeks. Clean the surface with a

Scotch-Brite

®

scour pad and mild household detergent taking

care to avoid making scratches. If the fouling is severe, lightly wet

sand with fine grade wet/dry paper.

Anti-fou

l

ing Paint

Surfaces exposed to salt water must be coated with anti-fouling

paint.

Use water-based anti-fouling paint only

. Never use ketone-

based paint since ketones can attack many plastics possibly

damaging the sensor. Reapply anti-fouling paint every 6 months

or at the beginning of each boating season.

Rep

l

acement Sensor & Parts

The information needed to order a replacement sensor is printed

on the cable tag. Do not remove this tag. When ordering, specify

the part number and date. For convenient reference, record this

information at the top of page one.

Lost, broken, or worn parts should be replaced immediately.

Hull nut

02-031-3

Obtain parts from your instrument manufacturer or marine dealer.

Gemeco

Tel: 803-693-0777

7

7

4

0

-

3

9

6

-

3

0

8

:

x

a

F

)

A

S

U

(

email: sales@gemeco.com

Airmar EMEA

Tel:

+33.(0)2.23.52.06.48

(Europe, Middle East, Africa) Fax:

+33.(0)2.23.52.06.49

email: sales@airmar-emea.com

3

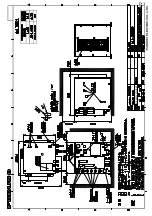

Summary of Contents for FCV-1900/B/G

Page 46: ...D 1 14 Apr 2015 H MAKI...

Page 47: ...D 2 15 Apr 2015 H MAKI...

Page 48: ...D 3 15 Jan 2015 H MAKI...

Page 50: ......

Page 51: ......