APPENDIX 2 INSTALLATION FOR TRANSDUCER (THRU-HULL MOUNT)

AP-7

Maintenance & Replacement

6. Sand and clean the area around the hole, inside and

outside, to ensure that the marine sealant will adhere

properly to the hull. If there is any petroleum residue inside

the hull, remove it with either mild household detergent or

a weak solvent (alcohol) before sanding.

7. Proceed with “Bedding” on page AP-5.

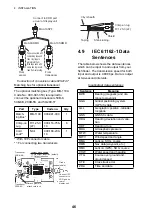

Figure 6. Preparing a cored fiberglass hull

Copyright © 2005 Airmar Technology Corp.

Checking for Leaks

When the boat is placed in the water,

immediately

check around the transducer for leaks. Note that very

small leaks may not be readily observed. Do not leave

the boat in the water for more than 3 hours before

checking it again. If there is a small leak, there may be

considerable bilge water accumulation after 24 hours. If

a leak is observed, repeat “Bedding” and “Installing”

immediately

(see pages AP-5 to AP-6).

Anti-fouling Paint

Model

Hull Nut

Washer

Isolation

Bushing

P19

04-004

09-452

-

B60

02-133-01

09-813-01

-

B150M

B619

02-143-01

09-1012-01

-

SS60

02-030

09-452

-

B75H/M/L

02-563-01

09-813-01

04-660-01

SS150M

SS619

02-520-02

09-452

04-186-1

Hull thickness

9-12 mm

(3/8-1/2") larger

than the hole

through the hull’s

outer skin

Inner skin

Core

Outer skin

Solid or hollow cylinder

Pour in

casting epoxy

Installation in a Cored Fiberglass Hull

The core (wood or foam) must be cut and sealed carefully.

The core must be protected from water seepage, and the

hull must be reinforced to prevent it from crushing under

the hull nut allowing the housing to become loose.

CAUTION

: Completely seal the hull to prevent water seepage

into the core.

1. Drill a 3 mm or 1/8" pilot hole from inside the hull (see

Figure 6). If there is a rib, strut, or other hull irregularity

near the selected mounting location, drill from the outside.

(If the hole is drilled in the wrong location, drill a second

hole in a better location. Apply masking tape to the outside

of the hull over the incorrect hole and fill it with epoxy.)

2. Using the appropriate size outside hull hole saw, cut a hole

from outside the hull through the outer skin only (see table

on page AP-5).

3. From inside the hull, using the appropriate size hull interior

hole saw, cut through the inner skin and most of the core.

The core material can be very soft. Apply only light

pressure to the hole saw after cutting through the inner

skin to avoid accidentally cutting the outer skin.

4. Remove the plug of core material, so the inside of the

outer skin and the inner core of the hull is fully exposed.

Sand and clean the inner skin, core, and the outer skin

around the hole.

5. If you are skilled with fiberglass, saturate a layer of

fiberglass cloth with a suitable resin and lay it inside the

hole to seal and strengthen the core. Add layers until the

hole is the correct diameter.

Alternatively, a hollow or solid cylinder of the correct

diameter can be coated with wax and taped in place. Fill

the gap between the cylinder and hull with casting epoxy.

After the epoxy has set, remove the cylinder.

Surfaces exposed to salt water must be coated with

anti-fouling paint. Use water-based anti-fouling paint only.

Never use ketone-based paint, since ketones can attack

many plastics possibly damaging the transducer. Reapply

anti-fouling paint every 6 months or at the beginning of

each boating season.

Cleaning

Aquatic growth can accumulate rapidly on the

transducer’s face, reducing its performance within weeks.

Clean the surface with a Scotch-Brite® scour pad and

mild household detergent, being careful to avoid making

scratches. If the fouling is severe, lightly wet sand it with

fine grade wet/dry paper.

Replacement Transducer & Parts

The information needed to order a replacement

transducer is printed on the cable tag. Do not remove this

tag. When ordering, specify the part number, date, and

frequency in kHz. For convenient reference, record this

information on the top of page AP-4.

Lost, broken, and worn parts should be replaced

immediately.

04-589-01

SS565

02-563-01

09-813-01

Spacer

-

-

-

04-646-01

-

04-646-01

-

Obtain parts from your instrument manufacturer or

marine dealer.

Gemeco

Tel:803-693-0777

(USA)

Fax:803-693-0477

email:sales@gemeco.com

Airmar EMEA

Tel:+33.(0)2.23.52.06.48

(Europe, Middle East, Africa)

Fax:+33.(0)2.23.52.06.49

email:sales@airmar-emea.com

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

www.airmar.com

Copyright © 2005 - 2013 Airmar Technology Corporation. All rights reserved.

Summary of Contents for FCV-588

Page 1: ...B R I L L GAIN...

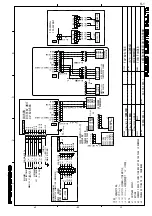

Page 72: ...D 1 13 Jan 2012 Y NISHIYAMA...

Page 73: ...D 2 13 Jan 2012 Y NISHIYAMA...

Page 74: ...D 3 13 Jan 2012 Y NISHIYAMA...

Page 75: ...D 4 13 Jan 2012 Y NISHIYAMA...

Page 76: ...D...