AP-8

APPENDIX 3 INSTALLATION OF

TEMPERATURE SENSORS

The installation instructions in this chapter are copied from the manufacturer's (AIRMAR

®

Tech-

nology Corporation) installation guide, which is included with your sensor.

The model numbers mentioned within the documentation should be read as follows:

• T42

T-04MSB

• T80

T-04MTB

17

-4

37

-0

2 re

v.

0

1

05

/28

/14

Thru-Hull, Analog

High-Precision Temperature Sensor

Model

T42

Tools & Materials

Safety goggles

Dust mask

Electric drill

Drill bit/hole saw/spade bit:

Pilot hole

3mm

or

1/8"

m

m

2

2

2

4

T

or

7/8"

Sandpaper

Mild household detergent

or

weak solvent (alcohol)

Marine sealant (suitable for below waterline)

Slip-joint pliers

Installation in a cored fiberglass hull (see page 2)

Hole saw for hull interior:

30mm

or

1-1/4"

Cylinder, wax, tape, and casting epoxy

Water-based anti-fouling paint (

mandatory in salt water

)

Sensor Installation

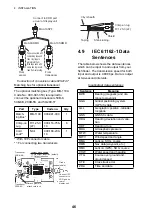

Hole Drilling

Cored fiberglass hull

— Follow separate instructions on page 2.

1. Drill a 3mm or 1/8" pilot hole from inside the hull. If there is a rib,

strut, or other hull irregularity near the selected mounting

location, drill from the outside.

2. Using the appropriate drill bit, cut a hole perpendicular to the

hull from outside the boat.

3. Sand and clean the area around the hole, inside and outside, to

ensure that the marine sealant will adhere properly to the hull. If

there is any petroleum residue inside the hull, remove it with

either mild household detergent or a weak solvent (alcohol)

before sanding.

Record the information found on the cable tag for future reference.

Part No._________________Date___________

Follow the precautions below for optimal

product performance and to reduce the risk of

property damage, personal injury, and/or death.

WARNING

: Always wear safety goggles and a dust

mask when installing.

WARNING

: Immediately check for leaks when the

boat is placed in the water. Do not leave the boat

unchecked for more than three hours. Even a small

leak can allow considerable water to accumulate.

CAUTION

: Never install a bronze sensor in a metal

hull because electrolytic corrosion will occur.

CAUTION

: Never install a metal sensor on a vessel

with a positive ground system.

CAUTION

: Never pull, carry, or hold the sensor by its

cable; this may sever internal connections.

CAUTION

: Never use solvents. Cleaner, fuel, sealant,

paint, and other products may contain solvents that can

damage plastic parts, especially the sensor’s face.

IMPORTANT

:

Read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

T42

INSTALLATION INSTRUCTIONS

OWNER’S GUIDE &

Applications

• Bronze sensor recommended for fiberglass or wood hull only.

• The hull must be a minimum of 8mm (5/16") thick at the

mounting location.

Mounting Location

Choose a location where the temperature sensor will be in contact

with the water at all times.

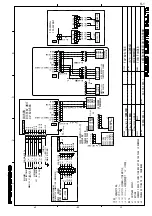

Summary of Contents for FCV-588

Page 1: ...B R I L L GAIN...

Page 72: ...D 1 13 Jan 2012 Y NISHIYAMA...

Page 73: ...D 2 13 Jan 2012 Y NISHIYAMA...

Page 74: ...D 3 13 Jan 2012 Y NISHIYAMA...

Page 75: ...D 4 13 Jan 2012 Y NISHIYAMA...

Page 76: ...D...