2-2

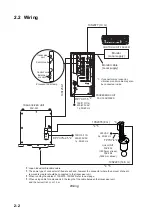

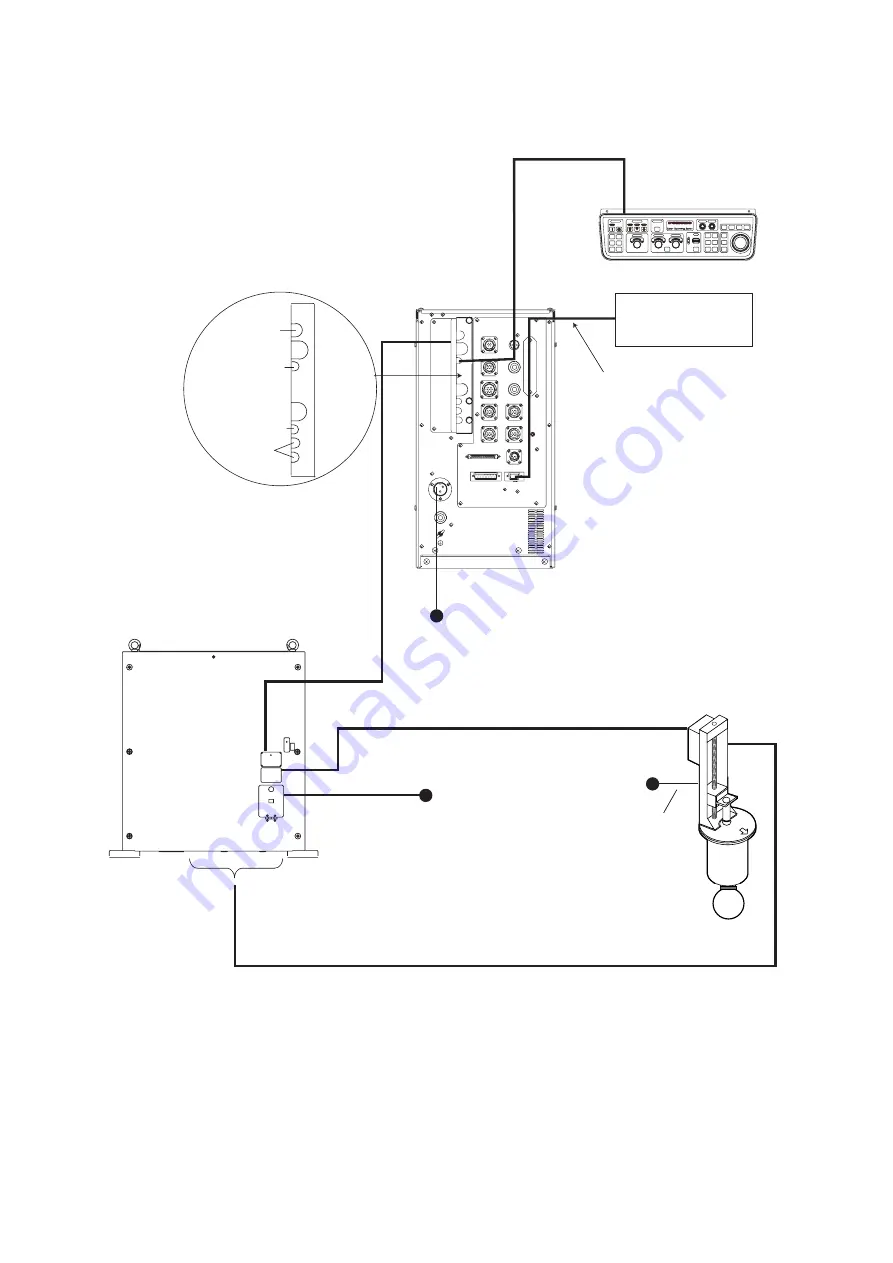

2.2 Wiring

Monitor

(Local supply)

CONTROL UNIT FSV-3001

PROCESSOR UNIT

FSV-3002/3002S

TRANSCEIVER UNIT

FSV-301

HULL UNIT

FSV-303

(1200 mm stroke)

FSV-304

(1600 mm stroke)

10S1258-1

Monitor cable

(Local supply)

10S2223 (14.6 m)

10S2078 (8 m)

100/110/115/

220/230 VAC

1

φ

, 50/60 Hz

*1

*1: If connector may loosen by

vibration monitor cable may also

be connected inside.

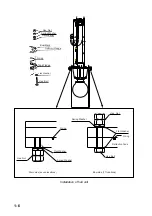

Processor unit clamp

Transceiver

unit

Control unit

Control unit

External

monitor

220 VAC

3

φ

, 50/60 Hz

10S2077 (10 m)

DPYCY-1.5 *2

TPYCY-4 *2

*3

*2: Japan Industrial Standard cable

*3: The same type of connector is fitted at each end, however the connector where the amount of sheath

removed is greater should be connected to the transceiver unit.

*4: When running the cables of 10S2078, 10S2223 refer to next page.

*5: When using cable for extension kit, the length of the cable between the transceiver unit

and the hull unit is 5 m or 10 m.

*4 *5

*4 *5

FSV-30

100/110/115/

220/230 VAC

1

φ

, 50/60 Hz

DPYCYS-2.5 *2

Wiring

Summary of Contents for FSV-30

Page 56: ...3 16 This page intentionally left blank ...

Page 60: ...4 4 This page intentionally left blank ...

Page 68: ...D 1 ...

Page 69: ...D 2 ...

Page 70: ...D 3 ...

Page 71: ...Y Hatai D 4 ...

Page 72: ...Y Hatai D 5 ...

Page 73: ...Takahashi T Y Hatai D 6 ...

Page 74: ...Takahashi T Y Hatai D 7 ...

Page 75: ...Y Hatai D 8 ...

Page 76: ...D 9 ...

Page 77: ...D 10 ...