Summary of Contents for FSV-35

Page 22: ...1 HOW TO INSTALL THE SYSTEM 1 16 This page is intentionally left blank ...

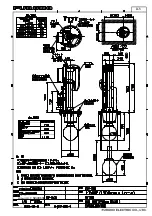

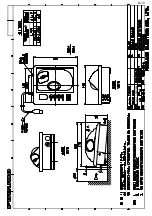

Page 55: ...D 1 13 Sep 2011 Y NISHIYAMA ...

Page 56: ...D 2 13 Sep 2011 Y NISHIYAMA ...

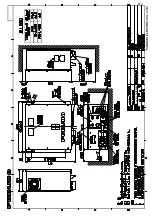

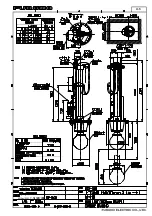

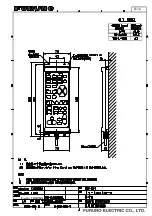

Page 57: ...D 3 5 Nov 2010 Y NISHIYAMA ...

Page 58: ...D 4 Y Hatai ...

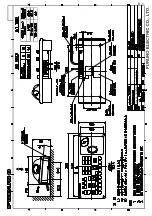

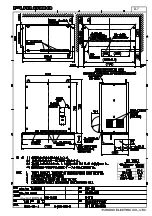

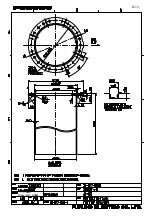

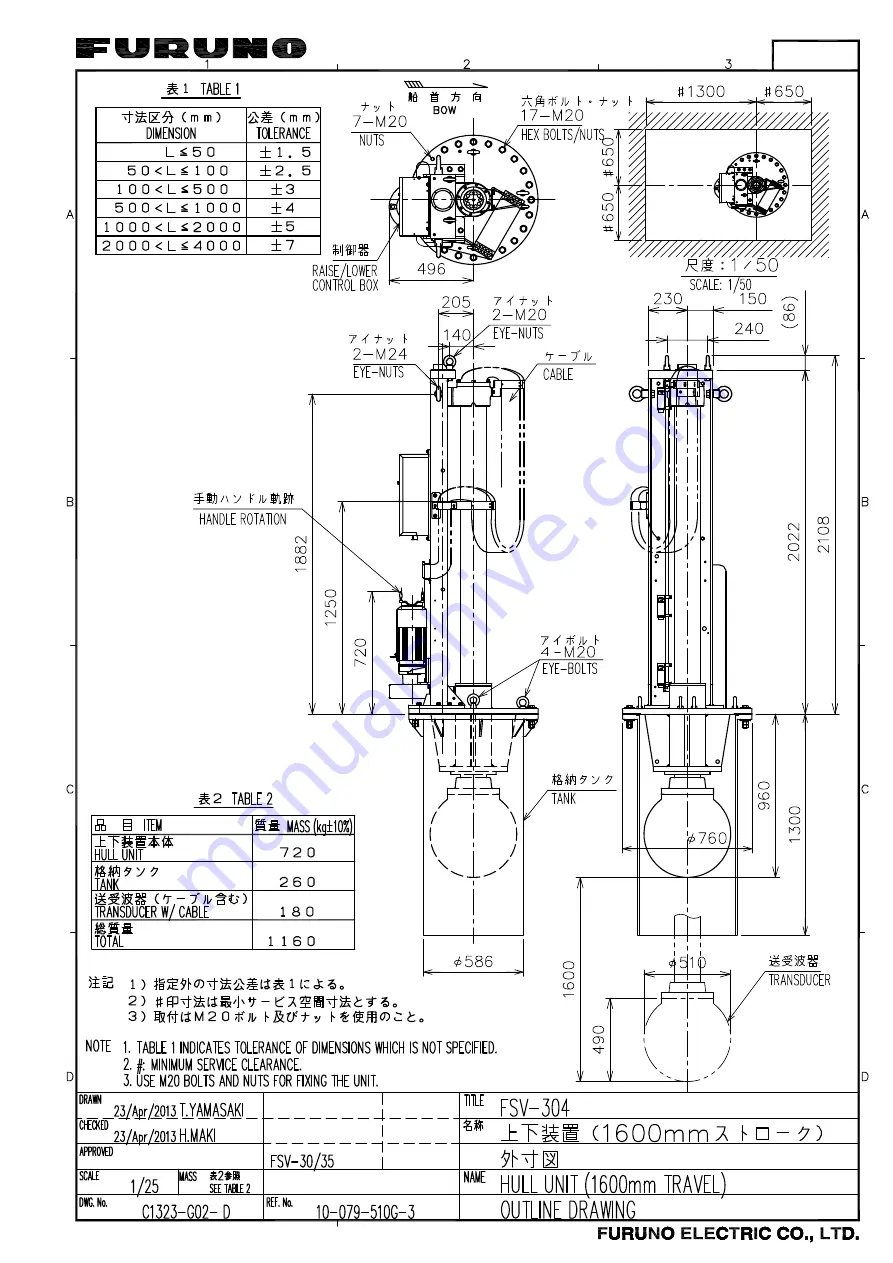

Page 59: ...23 Apr 2013 Y NISHIYAMA D 5 ...

Page 60: ...23 Apr 2013 Y NISHIYAMA D 6 ...

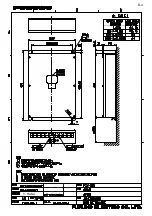

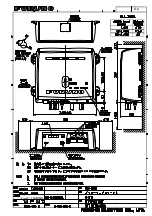

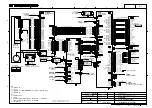

Page 61: ...D 7 13 Sep 2011 Y NISHIYAMA ...

Page 62: ...D 8 13 Sep 2011 Y NISHIYAMA ...

Page 63: ...13 Sep 2011 Y NISHIYAMA D 9 ...

Page 64: ...13 Sep 2011 Y NISHIYAMA D 10 ...

Page 65: ...13 Sep 2011 Y NISHIYAMA D 11 ...

Page 66: ...D 12 13 Sep 2011 Y NISHIYAMA ...