10. MAINTENANCE

10-17

10.11 Hull Unit (for Technicians Only)

The following procedures (outlined in this section) should only be conducted by a qual-

ified technician:

• Hull unit maintenance: section 10.11.1.

• Raising/lowering the transducer: section 10.11.2.

• Testing the brake in the hull unit: section 10.11.3.

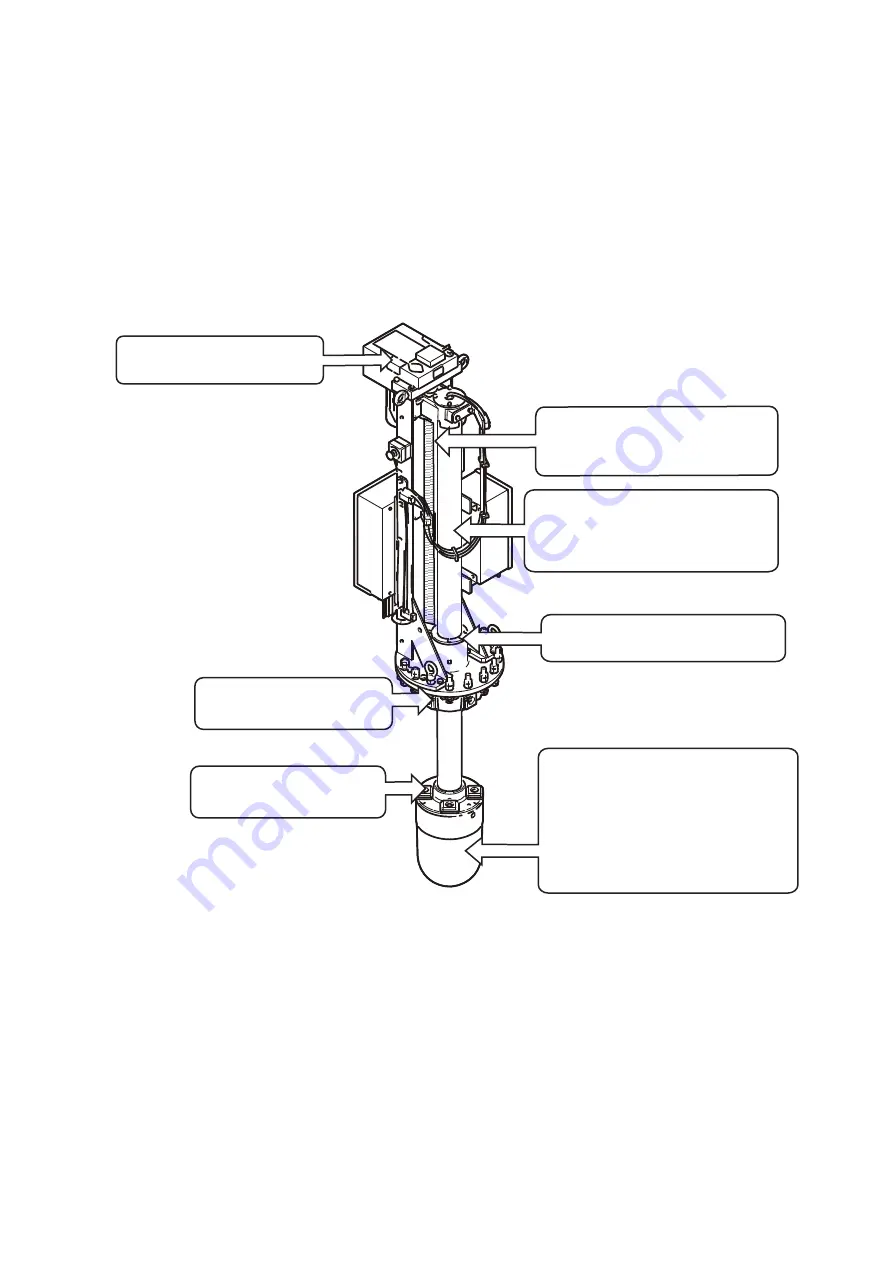

10.11.1 Hull unit maintenance

Note:

For how to change the sonar oil, see section 10.4.

Apply MOLYTONE Grease

#2 every six months.

Dry dock ship and clean transducer

face yearly. Apply single coat of

"SEATENDER 20"*

2

anti-foulant to

transducer face to keep marine life

off the transducer. Do not paint

metallic parts such as the

transducer flange.

Replace anti-corrosion

zinc plates yearly.

Replace anti-corrosion

zinc plates yearly.

Replace gasket if water is leaking

from the main shaft.

Coat the drive shaft with Daphne

Grease MP No.2 (IDEMITSU

KOSAN CO.,LTD.*

1

) every six

months.

Raise transducer and coat main

shaft with Daphne Grease MP

No.2 (IDEMITSU KOSAN

CO.,LTD.*

1

) every six months.

*

1

Equivalent greases:

SHOWA SHELL OIL: Shell Albania Grease S No.2

EXXON MOBIL: Mobilux EP No.2

NIPPON OIL CORPORATION: Multinox Grease No. 2

*

2

Equivalent coating:

CHUGOKU MARINE PAINTS, Ltd.: SEA GRANDPRIX 660HS

Summary of Contents for FSV-75

Page 1: ...OPERATOR S MANUAL www furuno com HALF CIRCLE COLOR SCANNING SONAR Model FSV 75 FSV 75 3D ...

Page 78: ...2 SLANT MODE 2 44 This page is intentionally left blank ...

Page 110: ...4 FISH FINDER MODE 4 12 This page is intentionally left blank ...

Page 144: ...5 3D MODE 5 34 This page is intentionally left blank ...

Page 148: ...6 NUMERIC GRAPHIC DATA DISPLAY 6 4 This page is intentionally left blank ...

Page 158: ...7 HOW TO CUSTOMIZE THE SONAR 7 10 This page is intentionally left blank ...

Page 216: ...10 MAINTENANCE 10 28 This page is intentionally left blank ...

Page 234: ...INDEX IN 3 W Warning messages 10 5 X XSECT ON OFF button 5 6 Z Zoom in out 5 4 ...

Page 235: ......