Summary of Contents for FSV-85-MARK-2

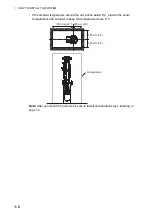

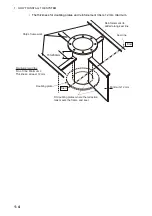

Page 34: ...1 HOW TO INSTALL THE SYSTEM 1 26 This page is intentionally left blank ...

Page 58: ...2 WIRING 2 24 This page is intentionally left blank ...

Page 86: ...D 1 7 Jul 2021 H MAKI ...

Page 87: ...D 2 7 Jul 2021 H MAKI ...

Page 88: ...D 3 7 Jul 2021 H MAKI ...

Page 89: ...D 4 7 Jul 2021 H MAKI ...

Page 90: ...D 5 7 Jul 2021 H MAKI ...

Page 91: ...D 6 7 Jul 2021 H MAKI ...

Page 92: ...22 Apr 2014 H MAKI D 7 ...

Page 93: ...D 8 24 Jun 2021 H MAKI ...

Page 94: ...D 9 24 Mar 2021 H MAKI ...

Page 95: ...D 10 24 Jun 2021 H MAKI ...

Page 96: ...D 11 24 Jun 2021 H MAKI ...

Page 98: ...D 13 17 Feb 2021 H MAKI ...

Page 99: ...28 Apr 2018 H MAKI D 14 ...

Page 100: ...D 15 13 Sep 2011 Y NISHIYAMA ...

Page 101: ...D 16 13 Sep 2011 Y NISHIYAMA ...

Page 102: ...D 17 13 Sep 2011 Y NISHIYAMA ...