2. WIRING

2-12

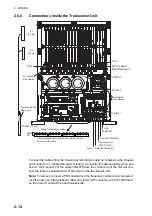

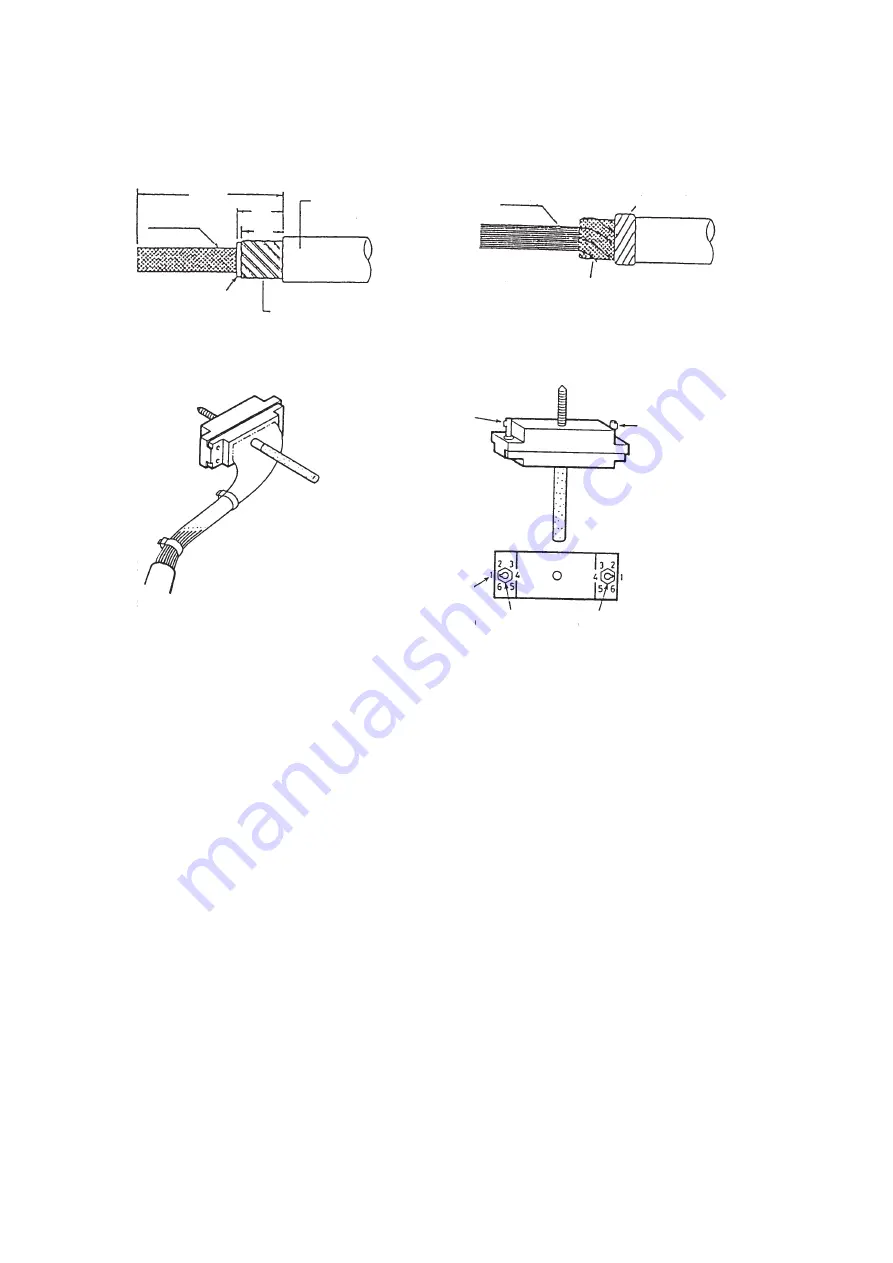

2.6

Transceiver Unit

2.6.1

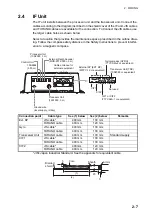

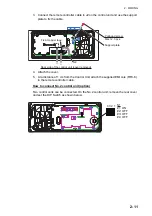

38P connector 00-8016-038-313761HVF (CN-B102)

How to fabricate 38P connector

How to assemble 38P connector

400

Shield

45

40

Anticorrosive

sheath

Armor

Vinyl Sheath

Core

Insulating tape

Expose cores then wind

shield around armor.

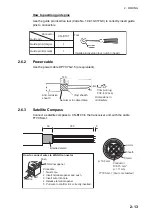

Guide Pin A

Guide Pin B

Guide Pin B

(Small)

Guide Pin A

(Large)

Position No.

Summary of Contents for FSV-85

Page 28: ...1 HOW TO INSTALL THE SYSTEM 1 20 This page is intentionally left blank ...

Page 56: ...3 ADJUSTMENTS AND CHECKS 3 10 This page is intentionally left blank ...

Page 67: ...12 Nov 2010 Y NISHIYAMA D 1 ...

Page 68: ...4 Feb 2011 Y NISHIYAMA D 2 ...

Page 69: ...5 Nov 2010 Y NISHIYAMA D 3 ...

Page 70: ...4 Apr 2014 H MAKI D 4 ...

Page 71: ...6 Jul 2012 Y NISHIYAMA D 5 ...

Page 72: ...Nov 22 06 T Matsuguchi D 6 ...

Page 73: ...22 Apr 2013 Y NISHIYAMA D 7 ...

Page 74: ...22 Apr 2013 Y NISHIYAMA D 8 ...

Page 75: ...26 Nov 2010 Y NISHIYAMA D 9 ...

Page 76: ...27 Dec 2010 Y NISHIYAMA D 10 ...

Page 77: ...Nov 22 06T Matsuguchi D 11 ...

Page 78: ...D 12 ...

Page 79: ...29 Mar 2011 Y NISHIYAMA D 13 ...

Page 80: ...13 Sep 2011 Y NISHIYAMA D 14 ...

Page 81: ...13 Sep 2011 Y NISHIYAMA D 15 ...

Page 82: ...Mar 14 07 R Esumi D 16 ...