NM 2830 e - 32 -

AUTOMATIC BUTTONHOLES

(CONTINUED)

5. Depress the foot controller and sew until the

machine stops automatically. The buttonhole is

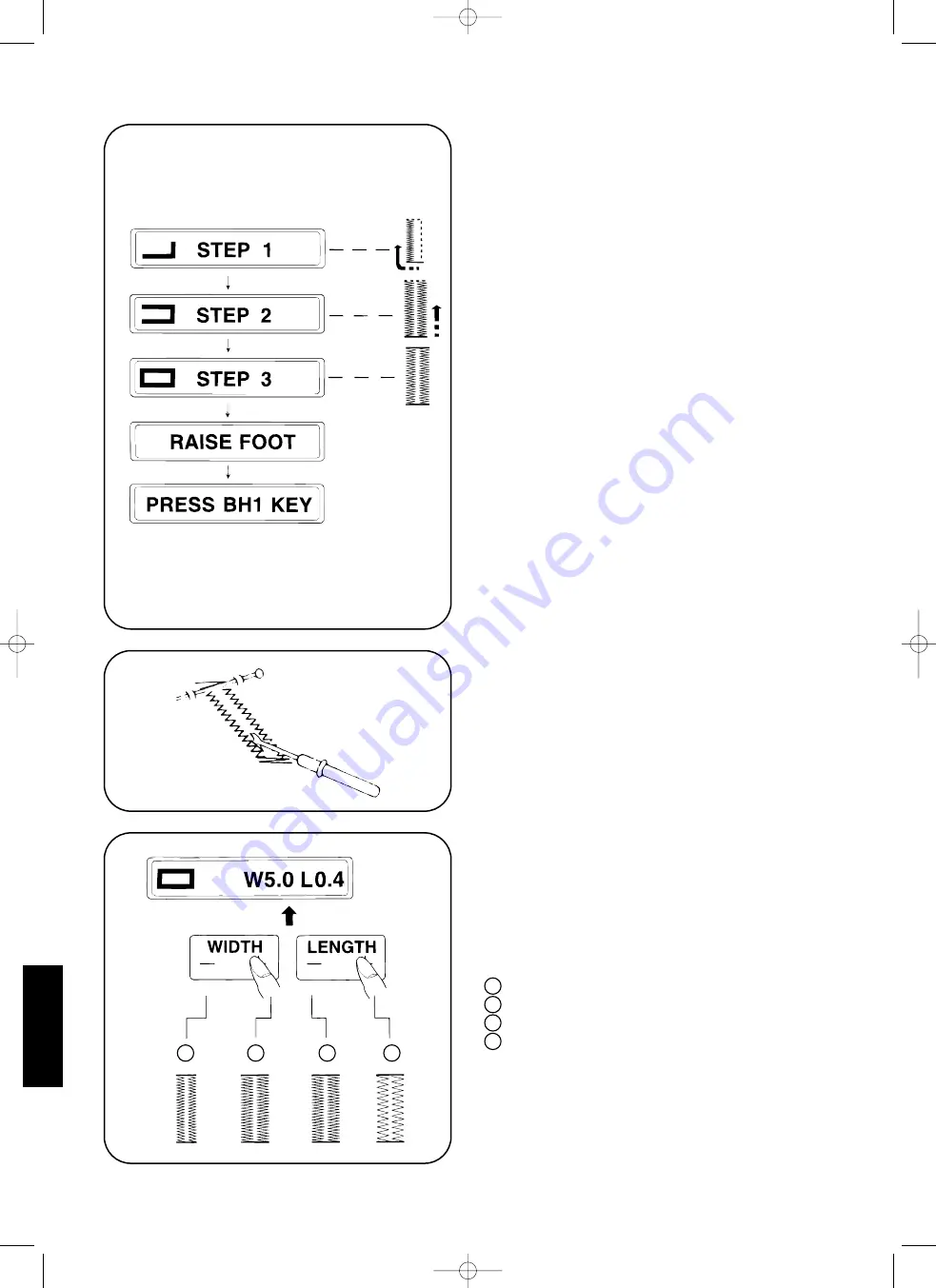

sewn automatically in the following order:

STEP 1: the front bartack and the left row

STEP 2: the right row

STEP 3: the back bartack

RAISE FOOT: the buttonhole is finished and you

can raise your foot from the foot controller.

PRESS BH1 KEY: to sew another buttonhole

press the key BH1 one more time.

6. Raise the presser foot and take the fabric out from

under the machine. Cut the threads and pull the

top thread to the left side of the fabric and secure

the threads.

7. Place a pin in the bartack and open the opening

of the buttonhole carefully with the seam ripper

without damaging the stitches.

ADJUSTING THE DENSITY OF THE ROWS OF

THE BUTTONHOLE

The pre-programmed settings are displayed on the

LCD screen. Adjust the pre-programmed settings by

pressing the "+"- and "-" parts of the keys of the stitch

width and the stitch length.

1

narrow rows (small stitch width)

2

wide rows (large stitch width)

3

dense rows (small stitch length)

4

less dense rows (large stitch length)

5.

7.

1

2

3

4

NM2830e 29/3/07 12:05 PM Page 32