42

Functions

Fail Safe Function/FAIL SAFE

(This function can only be used with HRS system.)

Fail safe function

This function moves the steering, throttle and channel 3 servos to a preset position

when the receiver cannot receive the signal from the transmitter for some reason.

When the servo operation position is not set, this function operates so that the servos

remain in the position they were in immediately before reception was lost. When the

signal from the transmitter can be received again, this function automatically resets.

- For gasoline engine cars, it is recommended that the throttle channel be set to the

direction that applies the brakes.

Battery fail safe function

When the receiver battery voltage drops to a certain voltage or less, this function

moves the throttle servo to the position set by fail safe function. When the voltage

recovers, this function automatically resets.

Setup items

F/S-ST: Steering setting

F/S-TH: Throttle setting

F/S-3C: Channel 3 setting

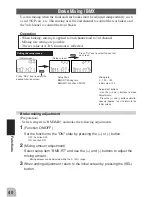

Fail safe function setup

(Preparation)

- Select the desired channel setup item and make the following adjustments.

1

(Servo position setup)

When the fail safe function operates, the steering stick, the throttle stick or

channel 3 lever remains in the desired operation position. When the (+)

and (-) buttons are pressed simultaneously for about 1 second, the servo

position is displayed and you can confirm that the function was set.

When you want to release the setting, press the (+) or (-) button. "OFF" is

displayed.

(Each channel can be set similarly.)

2

When ending adjustment, return to the initial screen by pressing the (SEL).

The servo position is

displayed when the

fail safe function

was set up.

(Initial screen)

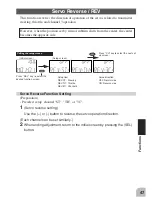

Press "SEL" key to select the

desired function screen.

Calling the setup screen

(Setup screen)

Press "CH" key to select the next set-

up screen.