11

Each end of each axis must be checked for calibration. If

needed, the axis can be calibrated using the remote

control.

You can also take the laser to a service center for

calibration.

Check and calibrate in this order:

Check both sides of X axis.

-- If X is within spec, proceed to check both sides of Y.

-- If X needs calibration, calibrate X.

Check both sides of Y axis.

-- If Y is within spec, proceed to final X to Y check

-- If Y needs calibration, calibrate Y; proceed to X to Y

check

Final X to Y check: cX, -X, +Y, -Y

Check Z and calibrate if necessary.

U

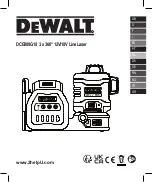

Checking X axis

1. Place the laser on a flat surface or tripod 50 or 100

ft. (30 m) away from a wall. Position so that -X is

facing the wall (this is the side of the laser with the

On/Off key).

2. Turn on the laser and remote control. There must be

no grade set in the laser. Both X and Y grade

displays must be at 0%.

3. Mark the location of the center of the beam. If it’s too

bright to see the beam, use a detector, or put in scan

mode.

4. Rotate the laser 180 degrees so that +X faces the

wall.

+Y

+X

-X

-

Y